When it comes to ensuring the safety and integrity of industrial pipes and containers, the Troxler leak test has proven to be a highly effective and reliable method. This non-destructive testing technique allows professionals to detect and locate even the smallest leaks in a variety of materials, including metals, plastics, and composites.

The Troxler leak test utilizes a combination of specialized equipment and advanced technologies to accurately identify leaks. By introducing a tracer gas into the system under test and scanning the surface with a sensitive detector, the presence of any leaks can be quickly detected. The equipment is designed to detect the smallest leaks, including those that are invisible to the naked eye.

What sets the Troxler leak test apart from other leak detection methods is its ability to provide accurate results in a timely manner. With this method, inspectors can perform a thorough examination of the entire system and pinpoint the exact location of any leaks, without the need for invasive procedures or extensive dismantling. This not only saves time and resources but also ensures that the system can be repaired or maintained promptly.

Regardless of the industry, the Troxler leak test is widely used for a variety of applications, including oil and gas pipelines, chemical storage tanks, and HVAC systems. Its reliable and efficient nature makes it an invaluable tool in preventing potential leaks, reducing downtime, and ensuring the safety of workers and the environment.

In conclusion, the Troxler leak test is a highly reliable and efficient method for detecting and locating leaks in industrial pipes and containers. Its non-destructive nature, coupled with its ability to detect even the smallest leaks, makes it an essential tool for maintaining the integrity and safety of various systems. By utilizing this method, industries can proactively address potential issues and prevent costly damages or accidents.

Troxler Leak Test: A Comprehensive Guide to Ensuring Leak-Free Systems

When it comes to maintaining integrity in industrial systems, ensuring that there are no leaks is of utmost importance. Leaks can lead to significant losses in terms of productivity, efficiency, and even safety. That’s why the Troxler leak test has become a widely used method for identifying and fixing leaks in various systems, from pipelines to storage tanks.

The Troxler leak test is a comprehensive and reliable method for detecting leaks in systems. It involves using a Troxler leak tester, which is a portable device that measures the pressure and flow rate of a gas or liquid within a system. By comparing the measurements before and after the test, any variations can indicate the presence of a leak.

The process of conducting a Troxler leak test involves several steps. First, the system to be tested needs to be isolated and prepared for the test. This may involve closing valves, draining fluids, or creating a temporary seal on openings. Once prepared, the Troxler leak tester is connected to the system, and the test is initiated. The tester will measure the pressure and flow rate, providing real-time data for analysis.

Interpreting the results of a Troxler leak test requires good understanding and analysis. Any variations in pressure or flow rate can indicate the presence of a leak, but it’s important to differentiate them from natural variations or other factors that may affect the test results. It’s also crucial to determine the severity of the leak and prioritize repairs accordingly.

Benefits of using Troxler leak test are numerous. By identifying and fixing leaks promptly, companies can prevent costly downtime and production losses. They can also improve safety by minimizing the risk of accidents or environmental contamination. Additionally, regular leak testing can help companies comply with regulatory requirements and demonstrate their commitment to environmental sustainability.

In conclusion, the Troxler leak test is an essential tool for ensuring leak-free systems in various industries. With its reliable measurements and comprehensive analysis, it provides companies with the means to identify and fix leaks promptly, improving productivity, safety, and environmental sustainability.

Understanding Troxler Leak Test: What is it and Why is it Important?

The Troxler leak test is a method used to determine if a sealed package or container is leaking. It is an important test in various industries, including food and pharmaceuticals, where the integrity of packaging is crucial to ensure product quality and safety. This test helps identify any potential leaks in packaging, which could lead to contamination, spoilage, or loss of product.

In the Troxler leak test, the package or container is pressurized with air or a specific gas, and any leaks are detected by measuring the rate at which the pressure decreases over a certain period of time. This test can be performed using different equipment, such as leak detection instruments or systems.

Why is the Troxler leak test important?

- Quality Assurance: The Troxler leak test is an essential part of quality assurance processes. It helps ensure that products are properly sealed and protected during storage and transportation.

- Product Safety: Leaks in packaging can lead to contamination or spoilage of products, posing a health risk to consumers. The Troxler leak test helps identify any potential leaks, allowing manufacturers to take necessary corrective actions.

- Regulatory Compliance: Many industries have strict regulations and standards regarding packaging integrity. The Troxler leak test helps companies comply with these regulations and demonstrate their commitment to product safety.

- Cost Savings: Detecting and fixing leaks early can prevent product loss and minimize waste. The Troxler leak test helps identify leaks before products reach the market, saving companies from potential financial losses.

- Customer Satisfaction: Ensuring the integrity of packaging helps maintain product quality, which in turn leads to customer satisfaction. The Troxler leak test plays a crucial role in delivering safe and reliable products to consumers.

How Does Troxler Leak Test Work?

Troxler leak test is a method used to detect leaks in sealed packages and containers. It relies on a process called gas permeation, where a gas is introduced into the package and any leaks are detected by measuring the rate at which the gas escapes. This method is widely used in industries such as food and beverage, pharmaceuticals, and electronics to ensure the integrity of their products.

The Troxler leak test process

1. Preparation: In this step, the package or container to be tested is prepared by ensuring it is clean and free from any contaminants. This is important to ensure accurate results and avoid false positives or negatives.

2. Gas injection: A specific gas, such as helium or carbon dioxide, is injected into the package through a small needle or probe. The gas is chosen based on its properties, such as its ability to diffuse through small leaks.

3. Sealing: After the gas is injected, the package is sealed tightly to prevent any further gas leakage.

4. Waiting period: The package is then left undisturbed for a certain amount of time to allow the gas to permeate through any potential leaks in the packaging material.

5. Gas detection: A gas detector is used to measure the concentration of the injected gas inside the package. If there are no leaks, the concentration should remain relatively stable. However, if there are leaks present, the concentration of the gas will decrease over time.

Advantages of Troxler leak test

- Non-destructive: The Troxler leak test does not damage or alter the tested packages, making it suitable for quality control purposes.

- High sensitivity: This method can detect very small leaks, ensuring the integrity of the products.

- Cost-effective: Troxler leak test equipment is relatively affordable compared to other leak detection methods.

- Quick results: The test can be completed in a relatively short amount of time, allowing for fast and efficient quality control.

In conclusion, the Troxler leak test is a reliable and efficient method for detecting leaks in sealed packages. It is widely used across various industries to ensure the integrity and quality of their products. The process involves injecting a gas into the package, sealing it, and then measuring the concentration of the gas to detect any leaks. The advantages of this method, such as non-destructive testing and high sensitivity, make it a popular choice for quality control purposes.

The Benefits of Troxler Leak Test

In various industries, such as the automotive, aerospace, and manufacturing sectors, ensuring the integrity and reliability of products is of utmost importance. One crucial aspect of quality control is leak testing, which helps identify any leaks or defects in components or systems. The Troxler leak test is a highly effective and efficient method that offers several benefits.

1. Accuracy: The Troxler leak test provides accurate results, enabling you to detect even the smallest leaks with precision. This ensures that faulty components or systems can be identified promptly, minimizing the risk of potential failures and ensuring product performance.

2. Efficiency: The Troxler leak test is a fast and efficient process, allowing you to test multiple components or systems within a short period. This helps optimize production processes and reduce downtime, ensuring that products can be quickly manufactured and delivered to customers.

3. Non-destructive testing: One significant advantage of the Troxler leak test is that it is a non-destructive testing method. This means that components or systems can be tested without causing any damage, allowing them to be used or sold without any compromise to their functionality or integrity.

4. Cost-effectiveness: Implementing the Troxler leak test in your quality control processes can result in significant cost savings. By detecting leaks early on, you can prevent costly repairs or replacements down the line. Additionally, the efficiency of the Troxler leak test helps optimize production and reduce operational costs.

5. Versatility: The Troxler leak test can be applied to various components or systems, making it a versatile testing method. Whether you need to test fuel systems, pipes, containers, or seals, the Troxler leak test can provide accurate results and help maintain the quality of your products.

In conclusion, the Troxler leak test offers several benefits, including accuracy, efficiency, non-destructive testing, cost-effectiveness, and versatility. By incorporating this testing method into your quality control processes, you can ensure that your products meet the highest standards of quality and reliability.

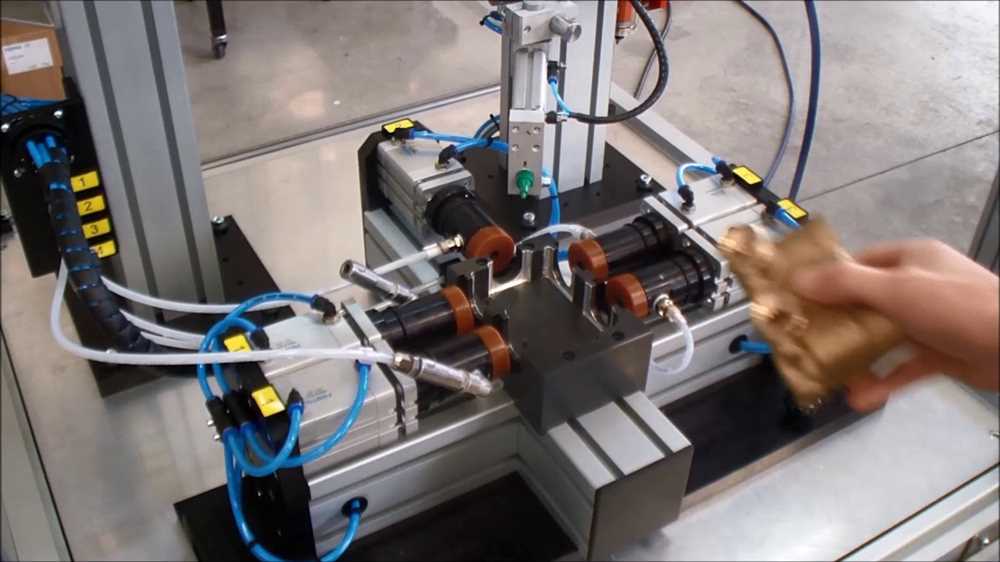

Troxler Leak Test Equipment: A Closer Look

Troxler leak test equipment is an essential tool used in various industries to detect and locate leaks in different types of containers, such as tanks, pipes, and valves. This equipment plays a crucial role in ensuring the safety and integrity of the containers, preventing potential leaks that could lead to hazardous situations, environmental damage, and financial losses. Let’s take a closer look at the key features and functions of Troxler leak test equipment.

1. Non-Destructive Testing: One of the significant advantages of Troxler leak test equipment is that it allows for non-destructive testing. This means that the equipment can detect and locate leaks without causing any damage to the containers being tested. This is particularly important when dealing with sensitive or expensive equipment that needs to remain intact.

2. High Sensitivity: Troxler leak test equipment is known for its high sensitivity, allowing it to detect even the smallest leaks. The equipment uses advanced sensors and technologies to identify changes in pressure, temperature, or other parameters that may indicate the presence of a leak. This high level of sensitivity ensures that no leaks go unnoticed, ensuring the safety and reliability of the containers.

3. Versatility: Troxler leak test equipment is designed to be versatile and adaptable to different types of containers and testing requirements. It can be used for testing various materials, including metals, plastics, and composites. The equipment can also be customized to fit specific testing scenarios, allowing for accurate and reliable results.

4. Easy to Use: Troxler leak test equipment is designed with user-friendliness in mind. The equipment is equipped with intuitive controls and interfaces that make it easy for operators to set up and perform tests. Some models may also have automated features, such as data logging and analysis, further simplifying the testing process.

5. High Accuracy: Reliability and accuracy are crucial when it comes to leak testing. Troxler leak test equipment is known for its high accuracy in detecting and locating leaks. The equipment is calibrated and tested to ensure precise measurements, minimizing the risk of false results and ensuring the integrity of the testing process.

In conclusion, Troxler leak test equipment offers a range of advanced features and functionalities that make it a preferred choice for leak testing in various industries. Its non-destructive testing capability, high sensitivity, versatility, ease of use, and high accuracy make it an invaluable tool for ensuring the safety and integrity of containers.

Conducting a Troxler Leak Test: Step-by-Step Guide

Performing a Troxler leak test is an essential part of ensuring the safety and integrity of a containment system. This test is commonly used in industries such as nuclear and oil and gas, where leaks can have severe consequences. The Troxler leak test involves the use of a Troxler gauge, which measures the rate of gas leakage from the system being tested.

Step 1: Preparation

Before conducting the Troxler leak test, it is important to properly prepare the equipment and testing area. Ensure that the Troxler gauge is calibrated and in good working condition. Clear the area of any potential hazards and make sure that all safety protocols are followed.

Step 2: Establish a Baseline

To establish a baseline, it is necessary to measure the background gas leakage rate in the absence of any leaks. This can be done by connecting the Troxler gauge to the containment system and allowing it to stabilize for a period of time, typically around 15 minutes. Record the baseline reading provided by the gauge.

Step 3: Introduce the Test Gas

Next, introduce the test gas into the containment system. This can be done by using a test gas generator or by manually injecting the gas into the system. It is essential to ensure that the test gas is compatible with the containment system and will not cause any damage or react with the materials.

Step 4: Measure the Leakage Rate

Once the test gas has been introduced, monitor the Troxler gauge for any changes in the leakage rate. The gauge will provide real-time measurements of the gas leakage, allowing for immediate detection of any leaks. Record the leakage rate at regular intervals, typically every 5 minutes, until the test is completed.

Step 5: Interpret the Results

After completing the test, analyze the recorded data to determine if there are any leaks in the containment system. Compare the leakage rate during the test to the baseline reading. If there is a significant increase in the leakage rate, it indicates the presence of a leak that needs to be addressed and repaired.

Step 6: Take Corrective Actions

If a leak is detected, it is crucial to take immediate corrective actions to fix the issue. Identify the source of the leak and determine the appropriate repair or containment measures. Once the necessary actions have been taken, retest the system to ensure that the leak has been successfully resolved.

By following these step-by-step instructions, the Troxler leak test can be effectively conducted to identify and address any leaks in a containment system. This test plays a vital role in maintaining the safety and reliability of industrial operations.