A gear pump test rig is a specialized setup used to test and analyze the performance of gear pumps. Gear pumps are rotary positive displacement pumps that use meshing gears to transfer fluids. They are widely used in various industries, including oil and gas, chemical, and automotive.

The gear pump test rig allows engineers and researchers to evaluate the efficiency, flow rate, pressure, and other performance parameters of gear pumps. It consists of a power source, a pump assembly, a flow measurement system, and data acquisition equipment. The power source can be an electric motor, a hydraulic system, or any other suitable mechanism that drives the pump.

During the test, the pump assembly is connected to the power source, and the fluid is circulated through the pump. The flow measurement system accurately measures the flow rate of the fluid, while the data acquisition equipment records various parameters such as pressure, temperature, and speed. This data is then analyzed to determine the pump’s performance characteristics, such as its efficiency and reliability.

The gear pump test rig is an essential tool for pump manufacturers and researchers to develop and improve gear pumps. It helps them understand the pump’s behavior under different operating conditions and optimize its design for maximum performance. It also enables them to identify any issues or inefficiencies in the pump and develop solutions to address them. Overall, the gear pump test rig plays a crucial role in ensuring the quality and reliability of gear pumps in various industries.

Gear Pump Test Rig

A gear pump test rig is a machine used for testing the performance and efficiency of gear pumps. Gear pumps are positive displacement pumps that use meshing gears to pump fluid. They are commonly used in various industries, including automotive, chemical, and oil and gas.

The gear pump test rig consists of a pump, a motor, a flow meter, pressure gauges, and other necessary instruments. The pump is connected to the motor, which drives the rotation of the gears. The flow meter measures the flow rate of the pumped fluid, while the pressure gauges monitor the inlet and outlet pressures. These instruments help in evaluating the pump’s performance and efficiency.

The gear pump test rig can be used for:

- Evaluating the pump’s volumetric efficiency, which is the ratio of the actual flow rate to the theoretical flow rate.

- Assessing the pump’s mechanical efficiency, which is the ratio of the output power to the input power.

- Determining the pump’s overall efficiency, which is the product of its volumetric and mechanical efficiencies.

- Measuring the pump’s pressure rise and pressure drop characteristics.

- Examining the pump’s performance under different operating conditions, such as varying speeds and fluid viscosities.

The gear pump test rig provides valuable data that can be used for pump selection, optimization, and troubleshooting. By testing the pump’s performance and efficiency, manufacturers and engineers can ensure that it meets the required specifications and operates effectively in its intended application.

In conclusion, the gear pump test rig is a crucial tool for evaluating the performance and efficiency of gear pumps. It helps in assessing their volumetric and mechanical efficiencies, as well as their pressure rise and pressure drop characteristics. The data obtained from the test rig enables manufacturers and engineers to make informed decisions regarding pump selection and optimization.

Overview of Gear Pump Test Rig

The gear pump test rig is a specialized equipment used for testing and evaluating the performance of gear pumps. Gear pumps are commonly used in various industries, such as automotive, chemical, and oil and gas, where precise and efficient fluid transfer is required.

The test rig is designed to simulate real-world operating conditions and measure the key parameters of gear pumps, such as flow rate, pressure, efficiency, and power consumption. It consists of several components, including a drive motor, a gear pump, a flow meter, pressure sensors, and a data acquisition system.

The drive motor is responsible for providing the rotational power to the gear pump, simulating the operation of the pump in an actual system. The gear pump itself consists of a pair of intermeshing gears that create chambers between the teeth of the gears, which are responsible for the fluid transfer.

The flow meter and pressure sensors are used to measure the flow rate and pressure of the fluid being pumped by the gear pump. These measurements are critical in evaluating the performance and efficiency of the pump. The data acquisition system collects all the measurements and records them for further analysis and comparison.

Overall, the gear pump test rig plays a vital role in the development and quality control of gear pumps. It allows manufacturers to ensure that their pumps meet the required specifications and perform reliably under different operating conditions. By accurately measuring and analyzing the performance of gear pumps, the test rig helps in improving the design and efficiency of these pumps, leading to enhanced performance and cost-effectiveness in various industrial applications.

The Importance of Gear Pump Testing

Gear pumps are commonly used in various industrial applications, including hydraulic systems, fuel transfer, lubrication, and chemical processing. These pumps play a critical role in ensuring the efficient and reliable operation of machinery and equipment. To ensure their performance meets the required standards, gear pump testing is of utmost importance.

Gear pump testing involves subjecting the pump to various operating conditions and measuring its performance parameters. This allows engineers to assess factors such as flow rate, pressure capability, volumetric efficiency, and overall efficiency. By conducting rigorous testing, any potential issues or limitations of the pump can be identified and addressed before it is put into service.

One key benefit of gear pump testing is that it helps in optimizing the design and performance of the pump. By analyzing the test data, engineers can identify areas where improvements can be made to enhance the pump’s efficiency and reliability. This may involve modifying the gear tooth profile, adjusting clearances, or optimizing the materials used. Testing also allows for the validation of design changes and the comparison of different pump configurations to determine the most effective solution.

Another important aspect of gear pump testing is its role in quality control. Testing ensures that every pump manufactured meets the required specifications and performs as expected. This is particularly crucial in industries where equipment failure can have severe consequences, such as in aerospace or oil and gas applications. Through testing, any manufacturing defects or abnormalities can be detected early on, preventing potential failures or accidents in the field.

In addition to performance and quality assessment, gear pump testing also plays a vital role in research and development. It allows engineers to gather valuable data on pump behavior and performance under different conditions, aiding in the advancement of pump technology. This data can be used to develop new design concepts, improve existing pump models, and explore new applications for gear pumps.

In conclusion, gear pump testing is essential for ensuring the reliability, performance, and safety of gear pumps in various industrial applications. By thoroughly testing these pumps, engineers can optimize their design, validate their performance, and identify any potential issues before they become critical. Whether it is for quality control or research purposes, testing is an integral part of the gear pump development process.

Design and Components of Gear Pump Test Rig

A gear pump test rig is a specialized equipment designed to evaluate the performance and characteristics of gear pumps used in various industrial applications. The rig consists of several key components and subsystems that work together to simulate real-world operating conditions and measure the pump’s performance under different scenarios.

1. Pump Module: The heart of the test rig is the pump module, which includes the gear pump under test. The pump is mounted on a motor-driven shaft and connected to the inlet and outlet lines. The pump module also includes pressure sensors, flow meters, and temperature sensors to measure key parameters.

2. Power Transmission System:

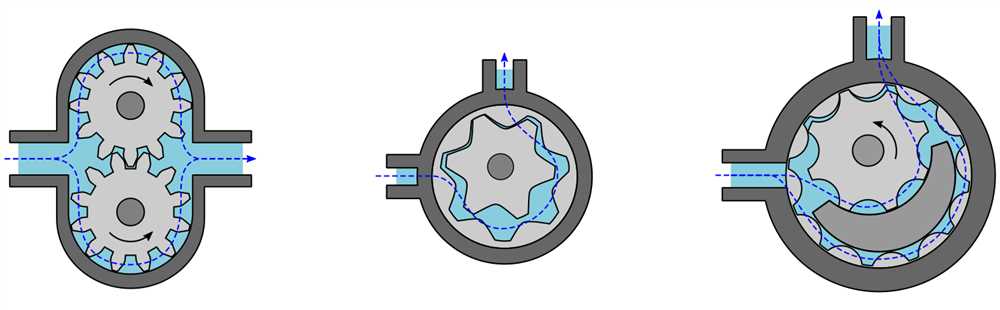

The gear pump test rig is an essential tool used to analyze the performance and characteristics of gear pumps. It operates on the principle of positive displacement, where the fluid is continuously trapped in the pump’s chambers and forced to move from the inlet to the outlet by the rotating gears.

This type of pump consists of two gears, one driving gear and one driven gear, enclosed within a casing. The driving gear is connected to a power source, such as an electric motor, and rotates at a constant speed. As it rotates, it transfers the motion to the driven gear, causing it to rotate in the opposite direction.

The fluid enters the pump through the inlet port and fills the space between the teeth of the gears. As the gears rotate, the fluid is trapped between the teeth and the casing, forming a series of pockets. The volume of the pocket decreases as the gears mesh, compressing the fluid and increasing its pressure.

The compressed fluid is then forced towards the outlet port as the gears continue to rotate. The pump’s design ensures a continuous and consistent flow of fluid, making it suitable for various applications where a precise flow rate is required.

The gear pump test rig measures key parameters such as flow rate, pressure, and efficiency. It allows for the adjustment of operating conditions, such as rotational speed and fluid viscosity, to analyze the pump’s performance under different scenarios. This data is crucial in determining the pump’s efficiency, reliability, and suitability for specific applications.

In conclusion, the gear pump test rig operates on the principle of positive displacement and provides valuable insights into the performance and characteristics of gear pumps. It allows for accurate testing and analysis, enabling engineers to make informed decisions regarding the selection, optimization, and maintenance of gear pumps in various industrial settings.

Parameters Measured in Gear Pump Test Rig Testing

In the gear pump test rig, various parameters are measured to evaluate the performance and efficiency of a gear pump. These measurements help in understanding the behavior of the pump under different operating conditions and determine its suitability for specific applications.

Flow rate: One of the key parameters measured in the gear pump test rig is the flow rate, which represents the volume of fluid pumped per unit time. This parameter is essential to assess the pump’s capacity and determine if it meets the desired requirements of the application.

Pressure: The pressure measurement is crucial to understand the pump’s ability to generate the required force to overcome system resistance and maintain a steady flow. It helps in evaluating the pump’s performance and efficiency under different operating conditions.

Power consumption: The gear pump test rig also allows for measuring the power consumption of the pump. This parameter provides insights into the pump’s energy efficiency and helps in optimizing its operation to minimize power consumption while maintaining the desired flow and pressure.

Temperature: Another important parameter measured in the gear pump test rig is the temperature of the pumped fluid. Monitoring the temperature helps in assessing the pump’s ability to handle and dissipate heat, which is crucial in preventing any damage or degradation of the pump and the fluid being pumped.

Noise and vibration: The gear pump test rig also enables the measurement of noise and vibration levels produced by the pump during operation. Monitoring these parameters helps in evaluating the pump’s overall performance, smoothness of operation, and identifying any potential issues or anomalies.

Leakage: The test rig allows for measuring and evaluating the amount of leakage in the pump. This parameter helps in assessing the pump’s sealing efficiency and identifying any potential leakage points. Minimizing leakage is essential for maintaining pump performance and preventing any fluid loss.

Overall, the gear pump test rig provides a comprehensive platform for measuring and evaluating various parameters critical to the performance, efficiency, and reliability of gear pumps. These measurements contribute to the development and improvement of gear pump designs, ensuring their optimal operation in different industrial applications.