When it comes to medical devices, ensuring their safety and efficacy is of utmost importance. This is especially true for catheters, which are widely used in various medical procedures. ISO 10555-1 is a standard that specifically addresses the testing requirements for catheters.

The ISO 10555-1 standard provides guidelines for the testing of catheters in order to evaluate their performance and safety. It covers a wide range of aspects, including mechanical properties, biocompatibility, sterility, and various other characteristics that are crucial for the functioning of catheters.

One of the main objectives of ISO 10555-1 is to ensure that the catheters are suitable for their intended use and that they meet the necessary quality standards. By following the guidelines provided by this standard, manufacturers can ensure the reliability and performance of their catheters, thereby minimizing the risks associated with their use in medical procedures.

ISO 10555-1 also emphasizes the importance of conducting comprehensive testing throughout the different stages of the catheter’s life cycle, from design and development to manufacturing and post-market surveillance. This helps to identify any potential issues or defects early on and allows for corrective actions to be taken, ensuring the ongoing safety and effectiveness of the catheters.

Iso 10555 1 General Catheter Testing Requirements

The ISO 10555-1 standard outlines the general testing requirements for catheters. Catheters are medical devices used for various purposes, including the drainage or infusion of fluids, and the introduction of instruments or other devices. Proper testing is crucial to ensure the safety and performance of catheters, as well as their compliance with regulatory requirements.

One of the key testing requirements specified in ISO 10555-1 is testing for dimensional and performance characteristics. This includes evaluating the catheter’s outer diameter, length, and functionality, such as the ability to resist kinking or collapsing. The standard also defines requirements for testing the flexibility and tensile strength of catheters, which are important factors in their usability and durability.

ISO 10555-1 also covers testing for biocompatibility, as catheters come into direct contact with the patient’s body. This includes testing for cytotoxicity, sensitization, and irritation, to ensure that the materials used in the catheter construction do not cause harm or adverse reactions. Additionally, the standard requires testing for hemolysis, which assesses the potential for the catheter to damage red blood cells.

Another important aspect of catheter testing outlined in ISO 10555-1 is sterility testing. Catheters must be sterile to prevent infection and other complications. The standard specifies the methods and criteria for testing the sterility of catheters, which involve subjecting samples to appropriate sterilization processes and then assessing their microbial contamination.

ISO 10555-1 also addresses the testing of catheter packaging and labeling. This includes ensuring that the packaging materials provide adequate protection and maintain the sterility of the catheter. The standard also requires accurate and clear labeling, including essential information such as the catheter type, size, and instructions for use.

In summary, ISO 10555-1 lays out the general catheter testing requirements to ensure the safety, performance, and compliance of these essential medical devices. Testing includes evaluating dimensional and performance characteristics, biocompatibility, sterility, and packaging and labeling. Adhering to these requirements helps to ensure that catheters meet the necessary standards for patient care and safety.

Definition and Purpose of Iso 10555 1 Standard

This standard is specifically focused on the requirements for catheters that are intended to be inserted into a patient’s blood vessels, such as those used for the administration of fluids, medications, or blood sampling. It establishes the essential characteristics and performance criteria that these catheters should meet to ensure their safety and effectiveness in clinical use.

The purpose of the ISO 10555-1 standard is to serve as a reference for manufacturers, regulatory authorities, and healthcare professionals involved in the design, production, and use of intravascular catheters. It provides a common framework and set of guidelines for evaluating the performance, safety, and quality of these medical devices.

The standard covers various aspects of catheter design, materials, dimensions, labeling, testing, and clinical performance. It outlines the minimum requirements and test methods for characteristics such as tensile strength, flexibility, catheter tip configuration, and biocompatibility. Compliance with this standard helps ensure that catheters are manufactured consistently and meet the necessary quality and safety standards.

Overall, the ISO 10555-1 standard plays a crucial role in promoting the development, evaluation, and safe use of intravascular catheters worldwide. Its implementation helps to minimize risks associated with catheter-related complications and improve patient outcomes in medical procedures involving these devices.

Scope of ISO 10555-1 Standard

ISO 10555-1 is an international standard that outlines the general catheter testing requirements for medical devices. The standard provides guidelines for testing the quality and safety of catheters used in clinical applications.

This standard applies to various types of catheters, including intravascular catheters, urinary catheters, and other types of invasive medical devices. It sets forth the requirements for the design, materials, and performance testing of these catheters.

Design Requirements:

- The standard specifies the design aspects, such as dimensions, shape, and markings, that catheters must adhere to.

- It also outlines the requirements for connectors and accessories that are used with catheters.

- Additionally, the standard covers the requirements for the packaging and labeling of catheters.

Material Requirements:

- ISO 10555-1 defines the minimum requirements for the materials used in catheter manufacturing, including biocompatibility and mechanical properties.

- The standard outlines the tests that need to be conducted to assess the material properties, such as tensile strength and elongation.

Performance Testing Requirements:

- The standard provides guidelines for testing the mechanical and functional performance of catheters, including their ability to withstand various loads and pressures.

- It also specifies the requirements for the evaluation of the lubricity, kink resistance, and flow characteristics of catheters.

Overall, ISO 10555-1 sets the framework for the testing and evaluation of catheters, ensuring their safety and reliability in clinical settings. Compliance with this standard helps manufacturers produce high-quality catheters that meet the needs of healthcare professionals and patients.

Design and Construction Requirements

The design and construction of catheters, as specified in ISO 10555-1, must comply with certain requirements to ensure their safety and effectiveness. These requirements cover various aspects, including materials, dimensions, markings, and performance characteristics.

Materials: The catheter must be made of biocompatible materials that will not cause any adverse reactions when in contact with the body. The material should be compatible with the intended use of the catheter and should not deteriorate or leach any harmful substances over time.

- Radiopacity: The catheter should have radiopaque markings to facilitate visualization under X-ray or fluoroscopy. These markings help healthcare professionals accurately position the catheter during insertion and guide subsequent procedures.

- Dimensions: The dimensions of the catheter, including length and diameter, must be specified to ensure compatibility with the intended application. The dimensions should be precise and within certain tolerances to ensure proper functionality.

- Markings: The catheter must be clearly and permanently marked with essential information, such as the manufacturer’s name or trademark, the catheter size or French size, the lot or batch number, and the expiry date. These markings ensure traceability and help in identifying and tracking the catheter throughout its lifecycle.

- Performance Characteristics: The catheter must meet certain performance criteria, including tensile strength, burst strength, kink resistance, and flexibility. These characteristics ensure that the catheter can withstand the forces and stresses encountered during use without failure.

Sterility Requirements

The sterility of catheters is of utmost importance in medical procedures to prevent infections and ensure patient safety. Therefore, ISO 10555-1 provides specific requirements for sterility testing of catheters.

According to ISO 10555-1, catheters should be sterile and free from viable microorganisms before they are used on patients. Sterility testing is conducted to verify that the catheters meet these requirements.

The testing procedure involves subjecting the catheters to various sterilization methods, such as steam sterilization or ethylene oxide sterilization. After the sterilization process, the catheters are assessed for sterility by performing microbiological testing.

The testing includes both qualitative and quantitative methods to detect the presence of microorganisms. Qualitative methods involve assessing the growth of microorganisms on culture media, while quantitative methods involve counting the number of viable microorganisms.

ISO 10555-1 also specifies the acceptable limits for sterility testing, such as the maximum allowable number of microorganisms. If the catheters pass the sterility testing and meet the specified limits, they are considered sterile and can be safely used in medical procedures.

Biocompatibility Testing Requirements

The ISO 10555-1 standard provides a set of general testing requirements for catheters. One important aspect of catheter testing is biocompatibility, which refers to the compatibility of the catheter materials with the biological system. Biocompatibility testing is essential to ensure that the catheter is safe and will not cause any adverse reactions when used in the human body.

The standard outlines various biocompatibility tests that need to be conducted to assess the safety and effectiveness of the catheter. These tests include cytotoxicity testing, which determines the potential toxicity of the catheter materials to cells. Hemocompatibility testing is also important, as it assesses the compatibility of the catheter with blood and evaluates its potential to cause blood clotting or other adverse reactions.

It is also necessary to conduct sensitization testing to identify any potential allergic reactions to the catheter materials. This involves exposing the catheter materials to immune cells and assessing their response. In addition, the ISO 10555-1 standard requires genotoxicity testing to evaluate the potential of the catheter materials to cause genetic damage.

To ensure the safety and performance of catheters, manufacturers must comply with these biocompatibility testing requirements as outlined in the ISO 10555-1 standard. By conducting these tests, they can identify any potential risks associated with catheter materials and make necessary modifications to ensure patient safety.

Summary:

- The ISO 10555-1 standard provides general testing requirements for catheters.

- Biocompatibility testing is essential to ensure the safety of catheters.

- Tests include cytotoxicity, hemocompatibility, sensitization, and genotoxicity testing.

- Manufacturers must comply with these testing requirements to ensure patient safety.

Compatibility with Vascular Access Devices

The compatibility of catheters with vascular access devices is a crucial aspect in ensuring their safe and effective use. ISO 10555-1 provides general testing requirements to evaluate the compatibility of catheters with various types of vascular access devices, such as needleless connectors and injection ports.

One of the key aspects of compatibility testing is assessing the physical and mechanical properties of the catheter and its interaction with the vascular access device. This includes evaluating the catheter’s ability to withstand pressures, its flexibility, and its resistance to kinking or damage during insertion and removal. Moreover, the compatibility testing also involves examining the catheter’s compatibility with the materials used in vascular access devices to ensure that they do not cause adverse reactions or affect the efficacy of the device.

ISO 10555-1 defines specific test methods for evaluating the compatibility of catheters with vascular access devices. These methods include assessing the catheter’s resistance to leakage, evaluating the catheter’s ability to maintain its position within the vascular access device, and examining the catheter-device interface for potential fluid or air ingress. The results of these tests provide valuable information about the suitability of the catheter for use with different types of vascular access devices.

In conclusion, ensuring the compatibility of catheters with vascular access devices is essential for their safe and effective use. ISO 10555-1 provides standardized testing requirements to evaluate this compatibility, covering aspects such as physical properties, mechanical properties, and material compatibility. By adhering to these standards, manufacturers can ensure that their catheters meet the necessary requirements and provide clinicians with reliable and compatible devices for vascular access procedures.

Performance Testing Requirements

The performance testing requirements specified in ISO 10555-1 for general catheters serve as crucial parameters to evaluate the functionality and reliability of these medical devices. These testing requirements aim to ensure the safety and effectiveness of catheters and provide guidelines for manufacturers, regulatory bodies, and healthcare professionals.

Burst pressure test: One of the key performance tests is the burst pressure test, which determines the maximum pressure a catheter can withstand before rupturing. This test evaluates the catheter’s strength and durability, ensuring it can tolerate the pressure encountered during normal use without failure.

Leakage test: Another important performance test is the leakage test, which determines the catheter’s ability to maintain a fluid-tight seal. This test involves subjecting the catheter to a specified pressure and checking for any leakage. It ensures that the catheter can effectively deliver fluids or medications without any leakage, minimizing the risk of infection or other complications.

- Tensile strength test: This test measures the maximum force a catheter can withstand before breaking. It assesses the catheter’s ability to withstand external forces, such as tension during insertion or removal, ensuring its structural integrity.

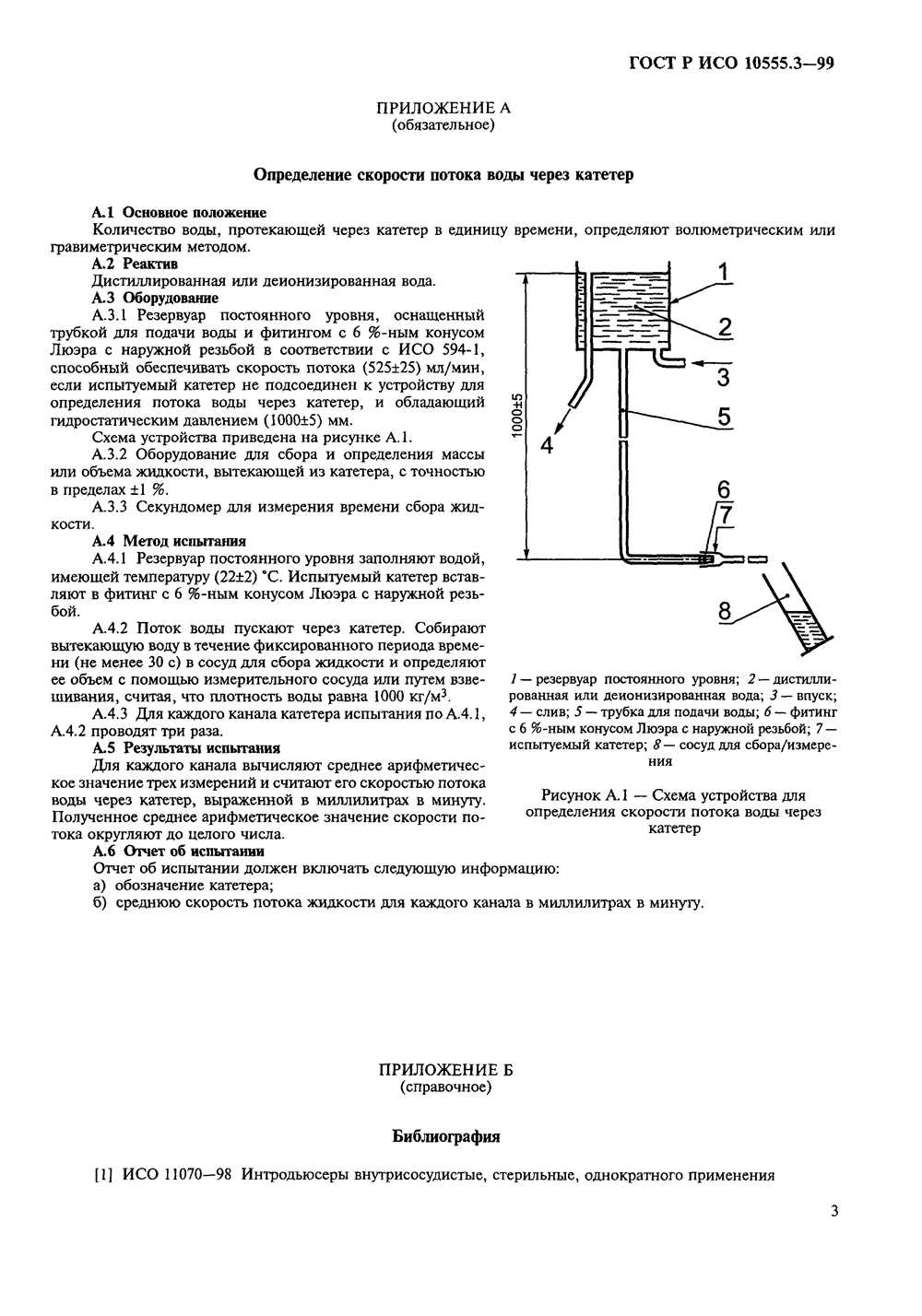

- Flow rate test: The flow rate test evaluates the catheter’s ability to deliver fluids or medications at the desired rate. It assesses the internal diameter and design of the catheter, ensuring accurate and consistent flow rates.

- Biocompatibility test: This test ensures that the materials used in the catheter construction are biocompatible and do not cause any adverse reactions when in contact with body tissues or fluids.

- Radiopacity test: The radiopacity test determines the visibility of the catheter under X-ray or other imaging techniques. It ensures that the catheter can be accurately positioned and monitored during procedures.

By complying with these performance testing requirements, manufacturers can produce catheters that meet the necessary safety and quality standards, providing healthcare professionals with reliable tools for various medical procedures.