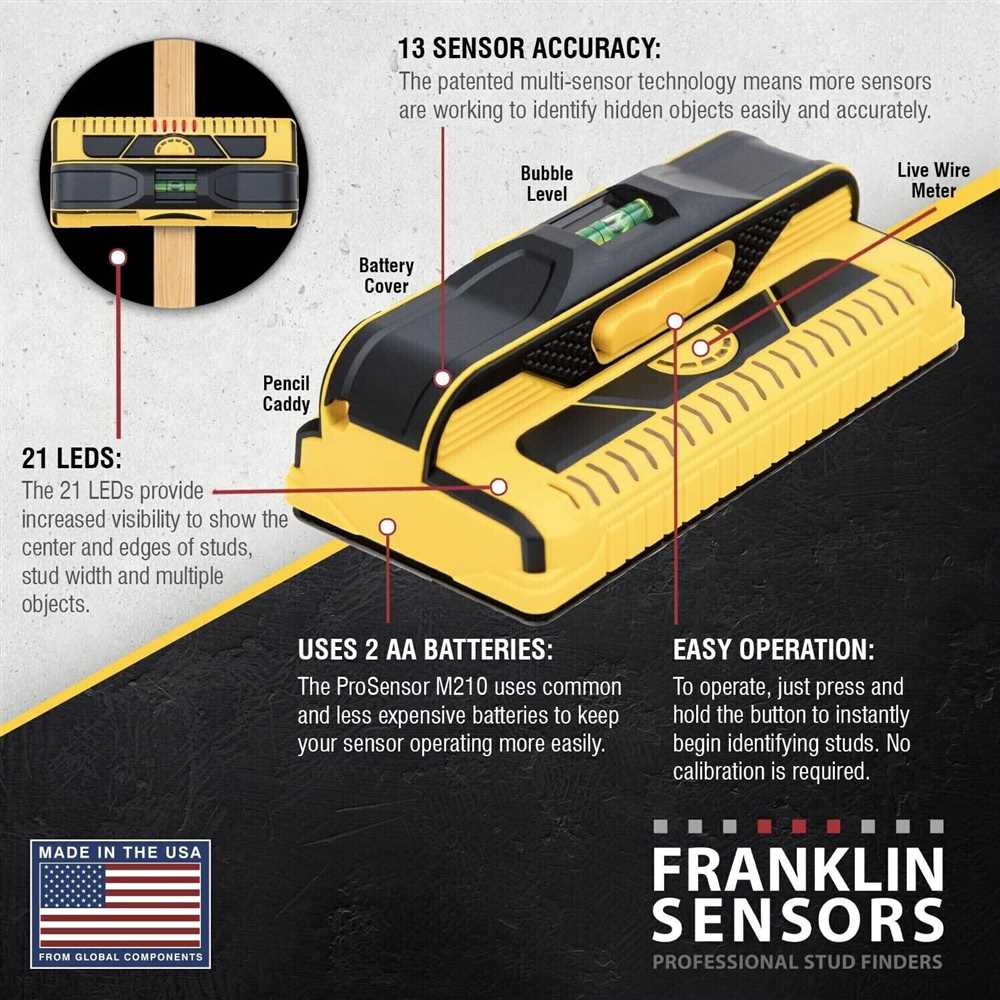

Software testing is an essential part of the development process, ensuring that programs and applications are running smoothly and free from bugs and errors. To perform effective testing, developers rely on a variety of tools and techniques. One such tool that has gained popularity among developers is the Franklin Tester.

The Franklin Tester is a powerful testing tool that offers a comprehensive set of features to help developers identify and fix bugs in their code. This tool provides a user-friendly interface that allows developers to quickly and easily run tests, view results, and track progress. With the Franklin Tester, developers can save both time and effort by automating the testing process and reducing the need for manual testing.

One of the key features of the Franklin Tester is its ability to simulate real-world scenarios, allowing developers to test their code in a controlled environment. This tool provides a wide range of testing options, including stress testing, performance testing, and regression testing. By running these tests, developers can identify potential issues and vulnerabilities in their code and make necessary adjustments to improve its performance and reliability.

Additionally, the Franklin Tester offers advanced debugging capabilities, providing developers with valuable insights into the root causes of bugs and errors. With its built-in debugging tools, developers can step through their code, analyze variable values, and track the flow of execution. This allows them to pinpoint and fix issues more efficiently, ultimately leading to a more stable and robust software application.

In conclusion, the Franklin Tester is an indispensable tool for developers looking to streamline their testing and debugging processes. With its wide range of features and intuitive interface, this tool enables developers to identify and fix bugs with ease, saving time and effort. By incorporating the Franklin Tester into their workflow, developers can ensure that their software applications are of the highest quality, meeting the expectations of their users.

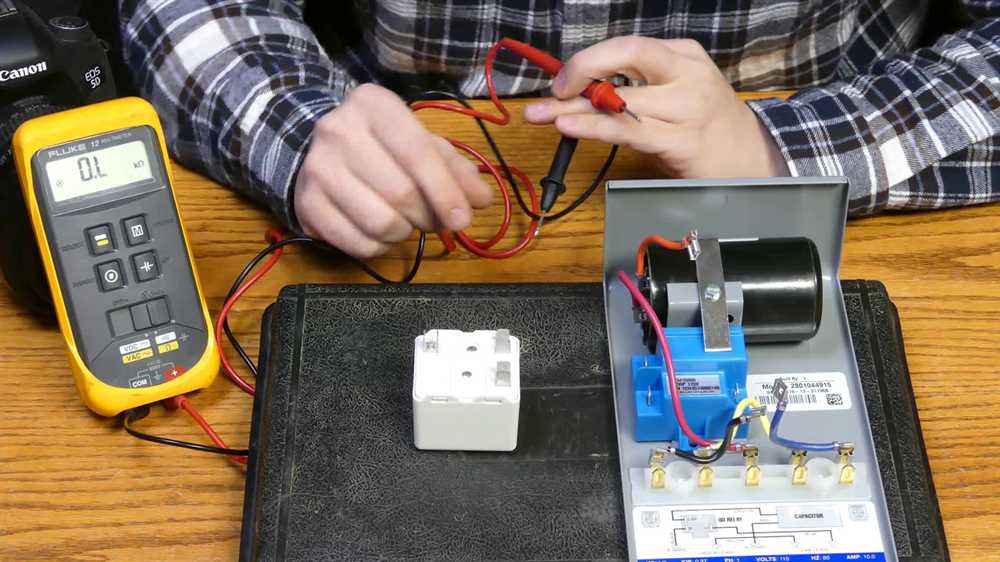

Ensuring Electrical Safety

Electrical safety is of utmost importance in any industrial or residential setting. Failure to prioritize electrical safety can result in serious injuries, fires, or even fatalities. It is therefore crucial to implement proper safety measures and regularly test electrical equipment for any potential hazards.

One effective tool for ensuring electrical safety is the Franklin tester. A Franklin tester is a device that measures the insulation resistance of electrical systems, cables, and equipment. By measuring the insulation resistance, the Franklin tester can detect any faults or deteriorations in the insulation, which can lead to electric shocks or short circuits.

Regularly conducting insulation resistance tests with a Franklin tester is essential to identify and prevent electrical hazards. These tests should be performed on all electrical circuits and equipment to ensure they meet the required safety standards.

During an insulation resistance test, the Franklin tester applies a high voltage to the electrical system. The tester then measures the current flowing through the insulation. If the measured resistance is below the specified threshold, it indicates that the insulation is compromised and needs to be repaired or replaced to prevent any potential safety risks.

In addition to insulation resistance tests, it is also essential to conduct other electrical safety checks, such as checking the grounding systems, tightness of connections, and proper functioning of circuit breakers. Regular maintenance and inspections, along with the use of tools like the Franklin tester, can significantly reduce the risk of electrical accidents and ensure the safety of both individuals and property.

- Regular insulation resistance tests can prevent electrical hazards and accidents.

- Franklin tester measures insulation resistance to detect faults in electrical systems.

- Other safety checks, like grounding systems and circuit breakers, should also be performed regularly.

Detecting faults and potential issues

Detecting faults and potential issues is a crucial step in any testing process. It is essential to identify and address any malfunctions or weaknesses in a system or device to ensure its optimal performance and reliability.

One of the effective tools for detecting faults and potential issues is the Franklin tester. This device is specifically designed to evaluate the integrity of electrical insulation and circuitry. By applying various voltage levels and measuring the resulting resistance, the Franklin tester can quickly identify any faulty or deteriorated insulation that may lead to electrical failures or risks of electrocution.

Importance of fault detection

Fault detection plays a vital role in ensuring the safety and reliability of electrical systems. It helps in preventing unexpected failures, costly downtime, and potential hazards. By identifying faults or weaknesses at an early stage, necessary repairs or maintenance actions can be taken to avoid further deterioration or potential accidents. Regular testing and fault detection also contribute to the longevity and optimal performance of electrical devices and systems.

Potential issues identified by a Franklin tester

- Insulation deterioration: The Franklin tester can identify any deterioration or weaknesses in the electrical insulation coating, which may lead to electrical short-circuits, voltage leakages, or insulation breakdowns.

- Moisture or water penetration: By measuring the resistance of the electrical circuit, the Franklin tester can detect if there is any moisture or water penetration. This is crucial as the presence of moisture can lead to corrosion, malfunctions, or electrical shocks.

- Damaged cables or wires: The Franklin tester can detect any faults or damages in cables or wires, such as cuts, abrasions, or loose connections. These issues can compromise the electrical performance and reliability of the entire system.

- Grounding problems: By analyzing the resistance and impedance values, the Franklin tester can identify any grounding issues, such as improper grounding or faulty earthing connections. This is essential for ensuring the safety of the electrical system and preventing the risk of electric shock.

In conclusion, detecting faults and potential issues is essential for maintaining the safety and reliability of electrical systems. The Franklin tester is an effective tool for identifying insulation deterioration, moisture penetration, damaged cables, and grounding problems. By regularly conducting tests with a Franklin tester, potential faults can be addressed promptly, minimizing the risk of failures, accidents, and downtime.

Quick and easy troubleshooting

In the world of testing, troubleshooting is an essential skill that allows you to quickly identify and resolve issues in your software or hardware. Being able to troubleshoot efficiently not only saves time and effort but also helps in providing a better user experience.

When it comes to the Franklin tester, having a systematic approach to troubleshooting can make the process quick and easy. Here are some steps you can follow:

1. Identify the problem

The first step in troubleshooting is to clearly identify the problem at hand. Take note of any error messages, unusual behavior, or performance issues that you are experiencing with the Franklin tester. This will help you narrow down the potential causes and focus your troubleshooting efforts.

2. Check for basic issues

Before diving deep into the Franklin tester, make sure to check for any basic issues that could be causing the problem. Ensure that the tester is properly connected, powered on, and that all cables and connections are intact. Sometimes, simple issues like loose connections or power supply problems can be the root cause.

3. Gather additional information

If the basic checks do not resolve the problem, it’s time to gather additional information. This could include looking at system logs, reviewing the tester’s documentation, or reaching out to support forums or communities for advice. Having more context and information about the problem will help you make more informed troubleshooting decisions.

4. Narrow down the potential causes

Using the information gathered, it’s time to narrow down the potential causes of the problem. This could involve isolating specific components, performing tests on different configurations, or analyzing the tester’s performance under different conditions. By systematically eliminating possible causes, you can focus your troubleshooting efforts on the most likely culprit.

5. Test and validate solutions

Once you have identified a potential solution or workaround, it’s important to test and validate them. Implement the solution and closely monitor the Franklin tester for any changes in behavior or performance. It’s always a good idea to document the steps taken and the results obtained during the testing process, as this can help in future troubleshooting efforts.

By following these steps, you can effectively troubleshoot issues with the Franklin tester and ensure smooth operation. Remember to stay patient, methodical, and thorough in your troubleshooting approach, and you’ll be able to quickly resolve any problems that arise.

Cost-effective solution for electrical maintenance

In today’s fast-paced world, efficient electrical maintenance is essential for ensuring smooth and uninterrupted operation of industrial and commercial facilities. However, traditional methods of testing and troubleshooting electrical systems can be time-consuming and costly. That’s where the Franklin tester comes in as a cost-effective solution for electrical maintenance.

The Franklin tester is a versatile and innovative tool designed to simplify and streamline the process of electrical maintenance. With its advanced features and functionalities, this tool offers an efficient and accurate way to identify electrical faults, perform insulation resistance tests, and measure earth resistance. By eliminating the need for multiple devices and manual calculations, the Franklin tester reduces complexity and saves valuable time.

The cost-effectiveness of the Franklin tester extends beyond the initial investment. Its user-friendly interface and intuitive operation make it easy to use, even for technicians with limited experience. This reduces the training and learning curve associated with traditional testing methods, saving both time and money. Additionally, the durability and long lifespan of the Franklin tester ensure that maintenance costs are kept to a minimum over time.

Furthermore, the Franklin tester offers the convenience of portability, allowing technicians to easily carry it to various locations and perform tests on a wide range of electrical systems. Its compact design and lightweight construction make it ideal for mobile electrical maintenance teams, reducing the need for additional equipment and resources. This versatility translates into cost savings and increased efficiency in the field.

In conclusion, the Franklin tester presents a cost-effective solution for electrical maintenance. By streamlining the testing process, reducing complexity, and offering portability, this innovative tool helps save time and money while ensuring the smooth and uninterrupted operation of electrical systems. Investing in the Franklin tester is an investment in efficiency, accuracy, and cost reduction for electrical maintenance.

Inability to Test Certain Types of Faults

While the Franklin tester is a reliable tool for detecting various types of faults in electrical systems, there are certain limitations to its testing capabilities. These limitations can prevent the tester from accurately identifying specific types of faults, leading to potential risks and challenges in troubleshooting and maintenance.

Limited Fault Detection in Complex Circuits: One of the main challenges of using the Franklin tester is its inability to test faults in complex circuits. The tester may struggle to accurately detect faults in circuits with intricate wiring configurations, multiple branches, or advanced electronic components. In such cases, more specialized testing equipment or techniques may be required to ensure comprehensive fault detection.

Incapability to Identify Intermittent Faults: Intermittent faults, which occur sporadically and may be influenced by various factors, can be particularly difficult to detect with the Franklin tester. This is because the tester usually relies on continuous testing and may not be able to capture transient faults that occur intermittently. To accurately identify intermittent faults, additional diagnostic tools and methods that focus on capturing event-specific data may be necessary.

Lack of Compatibility with Certain Fault Types: The Franklin tester may not be suitable for testing certain types of faults that require specialized testing procedures. For example, faults related to insulation breakdown or voltage surges may require specific high-voltage testing equipment that the tester may not possess. In such cases, alternative testing methods should be employed to ensure the accurate identification and resolution of these fault types.

Challenges in Testing Non-Electric Components: Another limitation of the Franklin tester is its inability to test non-electric components. The tester is designed primarily for electrical systems and may not be effective in detecting faults in mechanical or structural components of a system. To comprehensively analyze non-electric faults, complementary testing tools and techniques specific to those components should be utilized.

Not a substitute for professional electrical testing equipment

While the Franklin tester can be a useful tool for assessing the electrical safety of a system, it is important to note that it is not a substitute for professional electrical testing equipment. Professional electrical testing equipment is specifically designed to accurately measure and analyze various electrical parameters with a high degree of precision and reliability, providing comprehensive information about the system’s performance and potential risks.

While the Franklin tester can provide some basic information about the electrical safety of a system, it has limitations that should be taken into account. It may not be able to accurately measure certain critical parameters or identify potential issues that could pose a serious risk to the safety of the system and its users. Therefore, it is essential to use professional electrical testing equipment in addition to the Franklin tester to ensure a thorough evaluation of the system and minimize the risks associated with electrical installations.

Accuracy and reliability: Professional electrical testing equipment is designed to provide accurate and reliable measurements, ensuring that the data collected is precise and consistent. The Franklin tester, on the other hand, may not offer the same level of accuracy and reliability, as it is typically built for general use and may not have the same level of calibration and quality control as professional equipment.

Measurement capabilities: Professional electrical testing equipment often has a wide range of measurement capabilities, allowing for the assessment of various electrical parameters such as voltage, current, resistance, capacitance, and frequency. The Franklin tester, on the other hand, may have limited measurement capabilities and may not be able to accurately measure certain critical parameters. This can impact the overall assessment of the system’s electrical safety.

Detection of potential risks: Professional electrical testing equipment is specifically designed to detect and identify potential risks and issues that could pose a threat to the safety and functionality of the system. It can identify faults, abnormalities, and inconsistencies that may not be detectable with the Franklin tester alone. Therefore, relying solely on the Franklin tester may lead to overlooking potential risks and compromising the overall safety of the system.

In summary, while the Franklin tester can be a useful tool for basic electrical safety assessment, it should not be considered a substitute for professional electrical testing equipment. To ensure a comprehensive evaluation of the system’s electrical safety and minimize potential risks, it is essential to utilize professional equipment in addition to the Franklin tester.