Plastic is one of the most commonly used materials in our daily lives. From the packaging of our food and beverages to the construction of our furniture and electronics, plastic is everywhere. However, not all plastics are created equal, and it is important to know how different types of plastics behave under certain conditions, such as when they are exposed to fire. This is where the plastic burn test comes into play.

The plastic burn test is a method used to determine the type of plastic based on its reaction to fire. Each type of plastic has its own unique properties and chemical composition, which means that they will react differently when exposed to heat and flame. By observing the behavior of the plastic during a burn test, it is possible to identify the type of plastic and make informed decisions about its use and disposal.

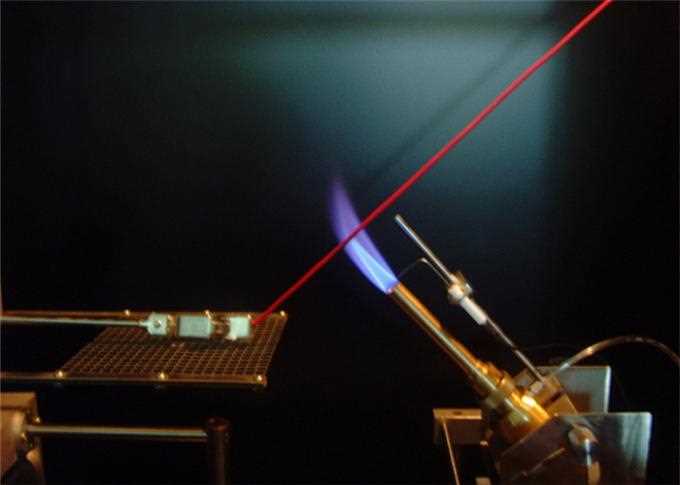

During a plastic burn test, the plastic is held over a flame or exposed to direct heat. As the plastic heats up, it will begin to melt and may release smoke and fumes. The color and odor of the smoke can provide valuable clues about the type of plastic being tested. Some plastics may produce a strong, acrid odor, while others may produce a sweet or chemical-like smell. It is important to note that burning plastic can release toxic gases and fumes, so proper ventilation and safety precautions should always be followed.

What is a Plastic Burn Test?

A plastic burn test is a method used to determine the type of plastic material by observing its reaction to heat. By subjecting a small piece of plastic to an open flame or hot object, various characteristics such as color, smell, and behavior can provide valuable clues about the composition of the plastic.

The burn test can help identify different types of plastics, such as polyethylene, polyvinyl chloride (PVC), polypropylene, and polystyrene, among others. It is often used in industries such as manufacturing, recycling, and product testing to ensure the correct use and handling of plastic materials.

During a plastic burn test, several key observations can be made:

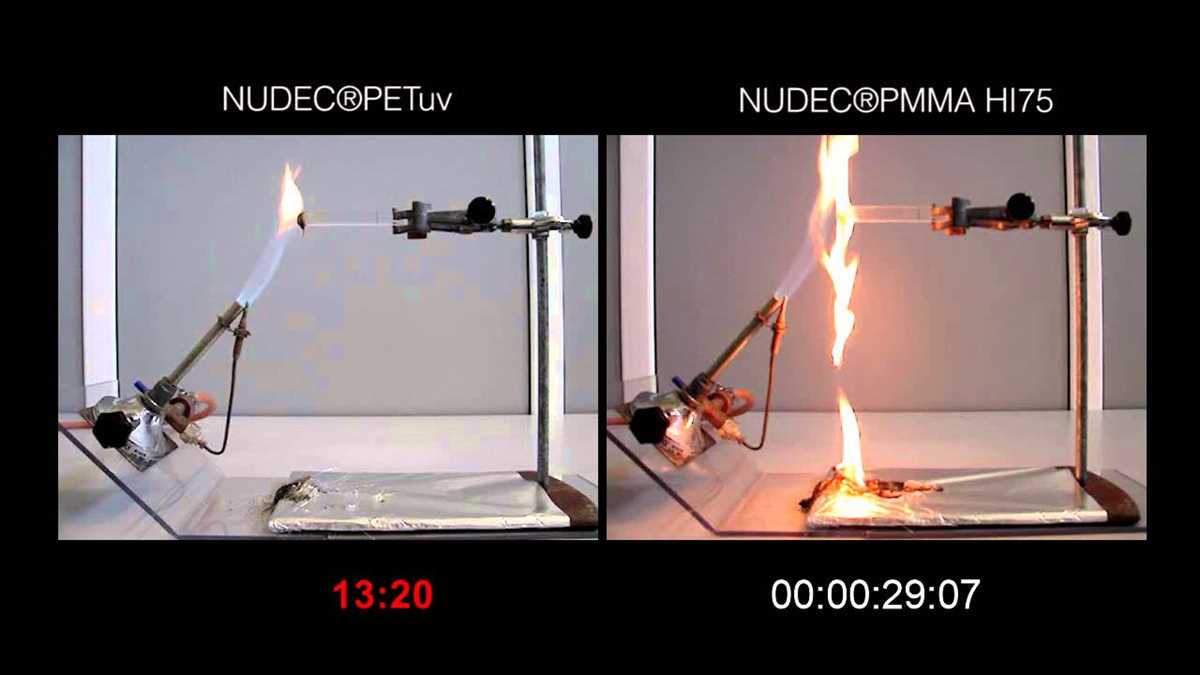

- Flame color: Different types of plastics produce different flame colors, such as blue, orange, yellow, or even green. These colors can indicate the presence of certain chemicals or additives in the plastic.

- Smoke: The smoke released during the burn test can have a distinct smell or color, which can provide information about the type of plastic being tested. For example, PVC may release a thick and black smoke.

- Behavior: Some plastics may drip, melt, or shrink when exposed to heat, while others may release a sticky residue or form a hard, charred surface. These behaviors can help differentiate between different types of plastics.

- Residue: After the plastic has burned, examining the residue left behind can offer further clues about the plastic type. For example, PVC may leave a powdery residue, while polystyrene may leave behind a brittle and glass-like residue.

It’s important to note that a plastic burn test should be conducted in a controlled environment and with proper safety precautions in place to avoid any potential hazards. Additionally, this test may not be suitable for all types of plastics, as some materials may not provide accurate or conclusive results through burning alone. Therefore, it is recommended to consult professional resources or experts for accurate identification of plastic materials.

Understanding the Purpose and Importance

The plastic burn test is a crucial method used to determine the type of plastic material, its composition, and its potential applications. This test involves subjecting a small sample of plastic to a controlled flame and observing its behavior and characteristics during the burning process. By analyzing the results of the burn test, scientists and engineers can gather valuable information about the plastic’s properties, such as its melting point, flammability, and resistance to heat. This data is essential for various industries, including manufacturing, recycling, and product development.

Identification of Plastic Types: One of the primary purposes of the plastic burn test is to identify the type of plastic material being tested. Different plastics have distinct chemical compositions and structures, making them behave differently when exposed to heat. By observing the color, smoke, odor, and flame characteristics during the burn test, experts can determine whether the plastic is polyethylene, polypropylene, polyvinyl chloride (PVC), polystyrene, or another type. This identification is crucial for proper recycling and waste management practices.

Data for Product Development: Understanding the burn behavior of plastic materials is essential for developing safe and reliable products. By knowing how a plastic will react to heat or fire, manufacturers can design products with appropriate fire resistance and flame retardant properties. This information is particularly crucial for industries that produce consumer goods, such as electronics, automotive parts, and construction materials. Without conducting burn tests, companies would struggle to ensure the safety and compliance of their products with industry standards and regulations.

- Recycling and Waste Management: The burn test is also useful in recycling and waste management processes. Different types of plastics have different melting points and properties, making them suitable for specific recycling methods. By identifying the plastic type through the burn test, recycling facilities can sort and process the plastics accordingly, maximizing the efficiency of the recycling process and minimizing waste. Additionally, knowing the flammability and combustibility of different plastics is crucial for proper disposal methods to avoid hazardous situations.

- Quality Control and Testing: The burn test is an essential tool for quality control and testing purposes. Manufacturers can use this method to verify the authenticity and quality of plastic materials used in their products. By comparing the burn characteristics of a sample with known standards and benchmarks, manufacturers can ensure that they are using the correct type and grade of plastic, preventing potential product defects and failures.

- Research and Development: The burn test also plays a significant role in the research and development of new plastic materials and formulations. Scientists and engineers can use this method to study the combustion behavior of different plastic compositions and additives. This knowledge can then be applied to develop new plastic materials with enhanced properties, such as improved flame retardancy or reduced environmental impact.

How to Perform a Plastic Burn Test?

If you need to identify a particular type of plastic, you can perform a plastic burn test. This simple test can help determine the type of plastic based on its behavior when exposed to heat. However, it is important to note that this test should be conducted with caution and in a well-ventilated area to avoid any potential hazards.

To perform a plastic burn test, follow these steps:

- Gather the materials: You will need a small piece of the plastic you want to test, a lighter or matches, a metal spoon, and a safe work area with good ventilation.

- Prepare the work area: Make sure you have a clean, flat surface to work on. Keep any flammable materials away from the test area.

- Light the lighter or matches: Use the flame to heat the metal spoon until it becomes hot.

- Perform the burn test: Hold the plastic piece with a pair of tongs or pliers and carefully bring it close to the hot spoon. Observe the plastic’s behavior as it reacts to the heat.

- Observe the results: Based on the plastic’s behavior, you can make an educated guess about its type. For example, if it burns quickly with a strong odor and leaves behind a black, sooty residue, it may be a type of plastic like polyethylene.

- Dispose of the plastic: Once you have finished the test, make sure to dispose of the plastic safely and clean the work area thoroughly.

Remember, the plastic burn test is not foolproof, and the results may not always be conclusive. Additionally, be cautious when handling flames and hot surfaces to avoid any accidents or injuries. If you are unsure or need to confirm the type of plastic, it is always best to consult a professional or use alternative testing methods.

Step-by-Step Procedure

The plastic burn test is a simple and effective method for identifying the type of plastic used in an object. It involves observing the behavior of the plastic when exposed to an open flame or heat source. Here is a step-by-step procedure to perform a plastic burn test:

1. Gather necessary materials

Before starting the burn test, make sure you have all the necessary materials on hand. These include a small sample of the plastic object you want to test, a lighter or match, a fireproof surface, and a pair of heat-resistant gloves.

2. Preparation and safety precautions

Prior to the burn test, ensure that you are in a well-ventilated area and away from any flammable materials. Wear the heat-resistant gloves to prevent any burns or injuries. Place the fireproof surface on a stable and non-flammable surface.

3. Ignite the flame

Using the lighter or match, ignite a small flame. Hold the plastic sample with the heat-resistant gloves and bring it close to the flame. Observe its initial behavior, such as melting, dripping, or charring.

4. Note the flame color and smell

As the plastic burns, pay attention to the color of the flame and any odor produced. Different types of plastics exhibit different flame colors, such as blue, yellow, or black. Similarly, each type of plastic has a distinct smell when burned.

5. Record observations

Take notes of all the observations made during the burn test. Record the initial behavior, flame color, and odor. These observations will be helpful in determining the type of plastic used.

6. Consult a plastic identification guide

After performing the burn test, consult a plastic identification guide or seek professional advice to determine the exact type of plastic used. Different types of plastics have unique characteristics and can be recognized based on their behavior during the burn test.

7. Properly dispose of the burnt plastic

Dispose of the burnt plastic responsibly according to recycling guidelines in your area. Plastic waste should be properly handled to minimize environmental impact.

By following this step-by-step procedure, you can effectively identify the type of plastic using the burn test method. It is important to exercise caution and adhere to safety precautions when working with fire or heat sources.

Interpreting the Results of a Plastic Burn Test

When conducting a plastic burn test, it is important to carefully observe and interpret the results in order to determine the type of plastic you are working with. This can be crucial information for recycling purposes or understanding the properties of a certain material.

First, it is important to note the color and appearance of the flame produced during the burn test. The color of the flame can give you an initial indication of the type of plastic. For example, if the flame is yellow, it suggests that the plastic is made of polyethylene or polypropylene. If the flame is blue, it may indicate the presence of PVC or polystyrene.

Another important factor to consider is the smell of the burning plastic. Different types of plastics have distinct odors when burned. For instance, burning polyethylene emits a sweet, waxy smell, while burning PVC produces a strong, acrid odor. Being aware of these smells can help you identify the type of plastic you are working with.

Furthermore, observing the behavior of the plastic as it burns can provide valuable information. Some plastics will melt and drip when burned, while others will shrink and curl. These characteristics can help narrow down the possibilities and provide additional clues about the type of plastic.

It is also worth noting that the residue left behind after the plastic has burned can be indicative of its composition. For instance, polyethylene often leaves behind a powdery residue, while PVC may leave a sticky or rubbery residue. These remnants can be further analyzed, if necessary, to confirm the findings of the burn test.

In conclusion, interpreting the results of a plastic burn test requires careful observation of factors such as flame color, smell, behavior, and residue. By considering these aspects, it is possible to identify the type of plastic and gain valuable insight into its properties and potential uses.

Identifying Different Types of Plastics

Plastics are widely used in our daily lives, from packaging materials to household items. However, not all plastics are created equal. Understanding the different types of plastics can help us make informed decisions about recycling, disposal, and even health and safety concerns. There are seven main types of plastics, each with its own unique properties and characteristics.

One of the most common ways to identify different types of plastics is through the burn test. This involves burning a small piece of plastic and observing its behavior. However, it’s essential to note that this method should be used with caution and only in well-ventilated areas, as burning plastics can release toxic fumes.

- Polyethylene (PE): This plastic type is commonly used in food packaging and plastic bags. It typically melts and drips when burned, with a slightly sweet or waxy smell.

- Polypropylene (PP): PP is often found in food containers, bottle caps, and automotive parts. When burned, it tends to melt and form a hard, bead-like residue.

- Polyvinyl Chloride (PVC): PVC is a versatile plastic used in pipes, vinyl records, and window frames. When burned, it produces thick, black smoke and emits a strong, acrid odor.

- Polyethylene Terephthalate (PET): PET is commonly used in beverage bottles and food containers. It melts and shrinks when burned and may emit a sweet or fruity odor.

- Polystyrene (PS): PS is often found in disposable food containers, foam packaging, and insulation materials. It melts and gives off a distinct, unpleasant smell similar to that of styrofoam.

- Polyamide (PA): PA, also known as nylon, is used in textiles, car parts, and industrial applications. It melts and may release a sweet or nutty odor when burned.

- Acrylonitrile Butadiene Styrene (ABS): ABS is commonly used in 3D printing, computer keyboards, and toys. It melts and releases a sharp, irritating smell when burned.

While the burn test can provide some insights into the type of plastic, it’s essential to consider other factors such as labeling, recycling symbols, and expert advice when identifying and handling plastics. Proper disposal and recycling of plastics are crucial in reducing environmental impact and promoting a sustainable future.

Applications and Benefits of Plastic Burn Tests

Plastic burn tests are widely used in various industries and applications for the evaluation and characterization of different types of plastics. These tests provide valuable information about the composition, behavior, and performance of plastic materials, enabling manufacturers, researchers, and regulators to make informed decisions and ensure product quality and safety.

One of the key applications of plastic burn tests is in the field of forensic science, where they are used to identify and differentiate different types of plastics found at crime scenes. By analyzing the burn patterns, flame retardant properties, and smoke emissions of plastic samples, forensic experts can determine the type and origin of the material, which can be crucial in criminal investigations. This information can also be used as evidence in court to link suspects to crime scenes or establish connections between different incidents.

The benefits of plastic burn tests extend beyond forensic science. In the manufacturing industry, these tests are used to assess the flammability of plastic materials and ensure compliance with safety regulations. By subjecting plastic samples to controlled burn tests, manufacturers can determine the ignition temperature, flame spread rate, and heat release properties of a material. This information is crucial in the design and production of products that require specific fire safety standards, such as electrical appliances, automotive components, and building materials.

- Burn tests also play a vital role in environmental monitoring and waste management. By examining the incineration characteristics of different types of plastics, researchers can develop better waste disposal methods and assess the environmental impact of burning plastic waste. This information can guide policymakers and recycling facilities in making informed decisions about waste management strategies, such as recycling, incineration, or landfilling.

- Moreover, plastic burn tests are used in the development of new flame retardant materials and additives. By studying the combustion behavior of different plastic samples, researchers can identify the most effective flame retardant formulations and optimize their performance. This knowledge contributes to the advancement of fire safety technologies and the development of more environmentally friendly flame retardant solutions.

In conclusion, plastic burn tests have numerous applications and benefits across various industries. From forensics to manufacturing, environmental monitoring to material development, these tests provide valuable insights into the behavior and properties of plastic materials. By leveraging the information obtained from these tests, professionals can make informed decisions, ensure product safety, and contribute to the advancement of fire safety standards and practices.

Industrial and Consumer Uses

Plastic burning tests have proven to be a valuable tool in various industrial and consumer applications. With the ability to easily identify the type of plastic, it becomes easier to determine its suitable use in different products.

Industrial Uses:

Plastic burn tests are commonly used in industries such as manufacturing, construction, and packaging. Manufacturers can use these tests to identify the type of plastic used in their products, allowing for efficient recycling and waste management practices.

In the construction industry, plastic burn tests can help determine the type of plastic pipes or insulation materials being used, ensuring they meet safety and quality standards.

Additionally, in the packaging industry, burn tests are crucial for identifying the type of plastic used in various packaging materials. This information helps companies design packaging that is environmentally friendly, as well as compatible with recycling processes.

Consumer Uses:

For consumers, plastic burn tests can be used as a handy tool to determine the authenticity of certain plastic products. It allows them to differentiate between genuine and counterfeit items, especially in the case of high-value goods.

Moreover, consumers who are concerned about the environmental impact of their purchases can use burn tests as a means to determine the recyclability of plastic products they encounter. This knowledge helps them make more informed choices and promote sustainable living.

Overall, plastic burn tests have proven to be an indispensable technique in various industries and for consumers alike. By providing valuable information about the type and nature of plastic, these tests contribute to more efficient manufacturing processes, improved waste management practices, and environmentally conscious consumer decisions.

Q&A:

What are some industrial uses of technology?

Some industrial uses of technology include automation of manufacturing processes, data analysis for improving efficiency, and predictive maintenance of machinery.

What are some consumer uses of technology?

Some consumer uses of technology include entertainment such as watching movies and playing video games, communication through social media and instant messaging, and online shopping.

How is technology used in the automotive industry?

Technology is used in the automotive industry for various purposes, such as improving fuel efficiency through engine optimization, implementing safety features like collision warning systems, and enhancing the driving experience with features like GPS navigation and entertainment systems.

What are some examples of technology used in the healthcare industry?

Examples of technology used in the healthcare industry include electronic medical records systems, medical imaging devices like MRI and CT scans, telemedicine for remote consultations, and robotic surgical systems.

What are some consumer uses of artificial intelligence?

Some consumer uses of artificial intelligence include virtual assistants like Siri and Alexa, personalized recommendations on streaming platforms like Netflix, and smart home devices like thermostats and lighting systems that can be controlled with voice commands.

What are some industrial uses of products?

Some industrial uses of products include manufacturing, construction, transportation, and energy production.