Performing a 7.3 HPOP pressure test is crucial for diagnosing issues with your high-pressure oil pump (HPOP). The HPOP is a vital component of the fuel system in many Ford Power Stroke engines, including the 7.3L. It provides the necessary high pressure to operate the fuel injectors, ensuring proper combustion and power delivery.

By conducting a pressure test, you can determine if your HPOP is functioning correctly or if there are any leaks or blockages affecting its performance. This test involves measuring the oil pressure at various points in the system, including the pump outlet and the injector ports. The results will help you identify any potential issues and allow you to take the appropriate steps for repairs or maintenance.

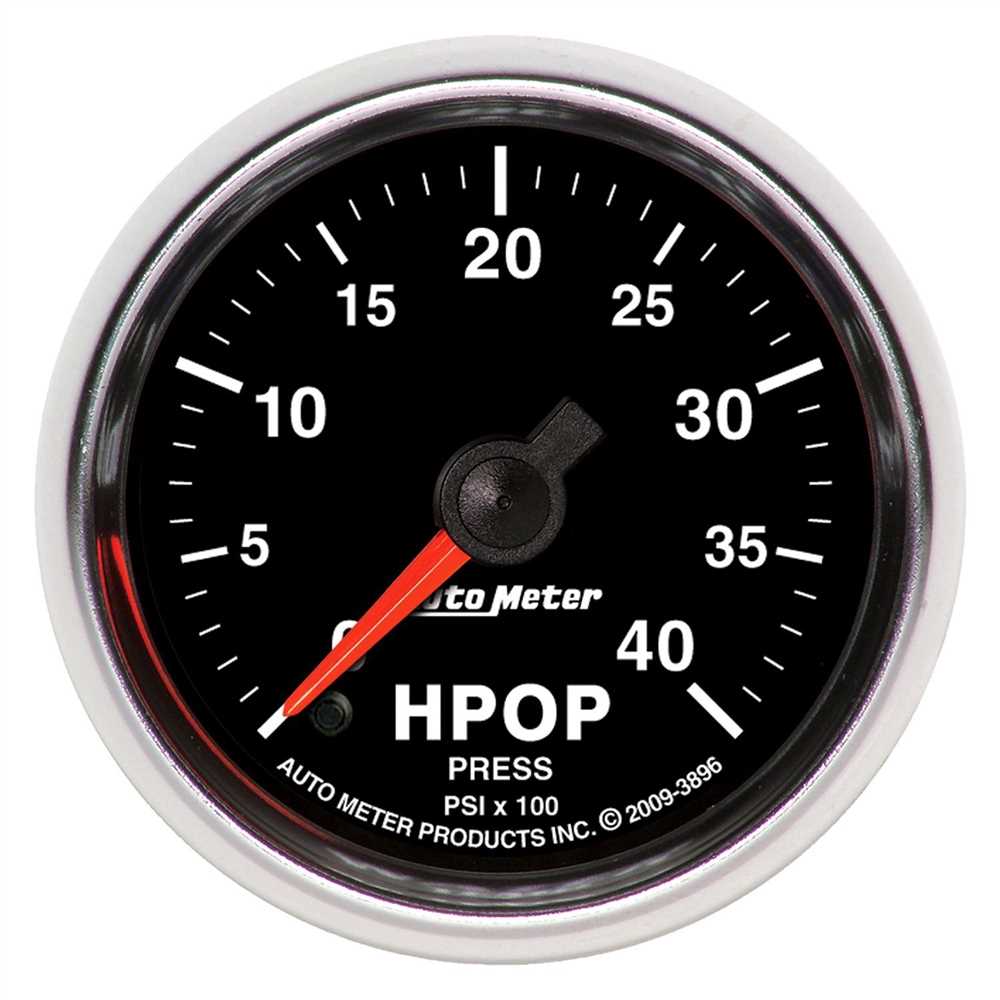

To perform a 7.3 HPOP pressure test, you will need a few key tools and equipment. These include a suitable pressure testing gauge, a pressure testing kit specific to the 7.3 Power Stroke engine, and an adapter that fits the HPOP fitting. It’s important to ensure that you have the right tools and follow the proper procedures to obtain accurate results.

During the pressure test, you will need to connect the pressure gauge to the appropriate ports and then run the engine to measure the oil pressure at idle and under load. Comparing these readings to the manufacturer’s specifications will indicate whether your HPOP is within the acceptable range or if any adjustments or repairs are necessary.

If your pressure test reveals low oil pressure, you may need to check for issues such as worn O-rings, a faulty HPOP, or a clogged oil filter. On the other hand, high oil pressure could indicate a faulty relief valve or a blockage in the system. Proper diagnosis is essential to address these issues promptly and prevent further damage to the engine.

In conclusion, performing a 7.3 HPOP pressure test is a crucial step in diagnosing and troubleshooting issues related to the high-pressure oil pump. By accurately measuring the oil pressure at various points in the system, you can identify any potential problems and take the necessary steps for repairs or maintenance. Remember to use the appropriate tools and follow the proper procedures to obtain accurate results.

3 HPOP Pressure Test: Step-by-Step Guide

In order to diagnose any issues with your 7.3 HPOP (High-Pressure Oil Pump) system, it is important to perform a pressure test. This test will help determine if the HPOP is generating the correct amount of pressure to properly operate your engine. Here is a step-by-step guide to conducting a 3 HPOP pressure test:

Step 1: Gather the necessary tools and equipment

Before starting the pressure test, make sure you have all the required tools and equipment. You will need a pressure gauge capable of reading high pressures, a T-fitting to connect the gauge to the HPOP system, and the necessary adapters and fittings for your specific engine model.

Step 2: Locate the HPOP test port

The HPOP test port is usually located on the HPOP reservoir or on the oil rail. Consult your vehicle’s service manual or an online resource to find the exact location of the test port for your engine model.

Step 3: Connect the pressure gauge

Once you have located the test port, connect the pressure gauge using the T-fitting and adapters. Make sure the connections are tight and secure to prevent any leaks during the test.

Step 4: Prepare the engine for the test

Start by ensuring the engine is off and the key is removed from the ignition. Then, relieve any residual pressure in the HPOP system by slowly loosening the test port fitting. This will help prevent any sudden release of pressure when conducting the test.

Step 5: Start the engine and monitor the pressure

With the pressure gauge connected and the engine off, start the engine and let it run at idle. Observe the pressure reading on the gauge and compare it to the recommended values for your engine model. If the pressure is within the acceptable range, your HPOP is functioning properly. If the pressure is below or above the recommended values, it indicates a potential issue with the HPOP system that requires further investigation.

Step 6: Perform additional tests or seek professional help if necessary

If the pressure test indicates an issue with the HPOP system, you may need to perform additional tests to pinpoint the exact problem. Alternatively, it is recommended to seek the assistance of a professional mechanic or diesel engine specialist who can diagnose and repair the issue.

By following this step-by-step guide, you can conduct a 3 HPOP pressure test and assess the performance of your HPOP system. Regular pressure testing can help identify any potential issues early on and prevent costly engine damage or breakdowns.

What is a 7.3 HPOP?

The 7.3 HPOP, or High-Pressure Oil Pump, is a crucial component in the 7.3L Power Stroke diesel engine used in Ford trucks. It is responsible for generating and supplying high-pressure oil to the fuel injectors, ensuring proper fuel atomization and injection. The HPOP plays a vital role in the engine’s performance and is an integral part of its operation.

The 7.3 HPOP operates by utilizing the engine’s crankshaft rotation to build up oil pressure. It takes in low-pressure oil from the engine’s oil pump and then intensifies it to high-pressure levels. This high-pressure oil is then transferred to the fuel injectors through the oil rail, enabling them to inject fuel at the precise moment and in the correct amount.

The HPOP consists of various components, including a gear-driven pump, a reservoir, pistons, and check valves. These components work together to generate the required pressure and deliver it to the injectors. The HPOP’s performance directly impacts the engine’s fuel delivery, power output, and overall efficiency.

Over time, the 7.3 HPOP may experience wear and tear, leading to decreased performance or even failure. Regular maintenance and checking the HPOP’s pressure can help diagnose and address any issues early on. Performing a pressure test on the HPOP can provide valuable insights into its condition and ensure proper functioning of the fuel injection system.

In conclusion, the 7.3 HPOP is a critical component in the 7.3L Power Stroke engine, responsible for generating and delivering high-pressure oil to the fuel injectors. Its proper functioning is essential for the engine’s performance and fuel efficiency, making regular maintenance and pressure testing crucial for optimal operation.

Why is a HPOP Pressure Test Important?

A high-pressure oil pump (HPOP) is a critical component in a diesel engine’s fuel system. It provides the necessary pressure to operate the fuel injectors, which in turn deliver fuel to the combustion chambers. Without proper HPOP pressure, the engine may experience performance issues, such as reduced power, rough idling, or even stalling. Therefore, conducting a HPOP pressure test is crucial to ensure the optimal functioning of the engine.

One of the main reasons why a HPOP pressure test is important is to diagnose potential issues with the fuel system. By measuring the pressure generated by the HPOP, mechanics can determine if it is within the manufacturer’s specifications. If the pressure is too low, it could indicate a problem with the pump itself, such as worn seals or a faulty internal mechanism. On the other hand, if the pressure is too high, it may suggest a clogged or restricted fuel line or a malfunctioning pressure relief valve. Identifying these issues through a pressure test allows for timely repairs or replacements, preventing further damage to the engine.

Moreover, a HPOP pressure test is essential for troubleshooting specific symptoms in the diesel engine. For example, if the engine is experiencing hard starting or misfires, a pressure test can help pinpoint the source of the problem. Low HPOP pressure may indicate a fuel delivery problem, while high pressure could be caused by a stuck injector or a faulty regulator. By accurately diagnosing the root cause, mechanics can efficiently address the issue and restore the engine’s performance.

In conclusion, a HPOP pressure test is a crucial step in maintaining the optimal functioning of a diesel engine’s fuel system. It allows for the early detection of problems, facilitating timely repairs and preventing further damage. By ensuring the proper HPOP pressure, mechanics can keep the engine running smoothly and maintain its performance and longevity.

Tools and Equipment Needed for the Test

When performing a 7.3 HPOP pressure test, it is important to have the right tools and equipment on hand. This test evaluates the performance of the high-pressure oil pump (HPOP), which is essential for the proper functioning of the engine. Here are some of the tools and equipment that are needed for the test:

1. Pressure Gauge:

A pressure gauge is a crucial tool for measuring the HPOP’s pressure output accurately. Make sure to use a gauge that is specifically designed for high-pressure applications and can handle the pressure required for the test. It is important to choose a gauge that has the proper range and accuracy for the test.

2. Test Fitting:

A test fitting is used to connect the pressure gauge to the HPOP system. The fitting should be compatible with the engine model being tested. It is important to ensure a tight and secure connection between the test fitting and the HPOP system to prevent any leaks during the test.

3. Wrenches and Sockets:

Having a set of wrenches and sockets of various sizes is essential for removing and installing components during the test. These tools are needed to access and remove the HPOP system as well as other engine components that may need to be inspected or replaced.

4. Safety Equipment:

Safety should always be a priority when working on any vehicle. Make sure to have safety equipment such as gloves and safety glasses to protect yourself from potential hazards. It is also a good idea to have a fire extinguisher nearby in case of any emergencies.

By having the right tools and equipment for the 7.3 HPOP pressure test, you can ensure that the test is conducted accurately and safely. These tools will allow you to measure the pressure output of the HPOP system and identify any potential issues that may affect the engine’s performance. Remember to always consult the manufacturer’s guidelines and specific instructions when performing this test to avoid any costly mistakes or damage.

Step 1: Prepare the Vehicle

Before performing the HPOP (High Pressure Oil Pump) pressure test on your vehicle, it is crucial to properly prepare the vehicle to ensure accurate results and avoid any potential damage or safety hazards. Here are the steps to follow:

1. Park the Vehicle

Park the vehicle on a level surface and engage the parking brake. This will prevent any unwanted movement during the test and ensure a stable working environment.

2. Turn off the Engine

Turn off the engine and remove the key from the ignition to avoid any accidental starting. This is a safety measure that should always be followed when working on the engine.

3. Allow the Engine to Cool Down

Before proceeding with the HPOP pressure test, it is recommended to allow the engine to cool down to avoid any potential burns or injuries. This is especially important if the engine has been running recently.

4. Gather the Necessary Tools and Equipment

Make sure you have all the necessary tools and equipment required to perform the HPOP pressure test. This may include a pressure gauge, fittings, hoses, and any specific tools mentioned in the test procedure. Having everything readily available will save you time and ensure a smooth testing process.

5. Familiarize Yourself with the Test Procedure

Prior to starting the HPOP pressure test, take the time to read and understand the test procedure and instructions provided by the manufacturer. Familiarize yourself with the steps involved, required pressures, and any precautions or specific details mentioned. This will ensure a smoother testing process and accurate interpretation of the results.

By properly preparing the vehicle before conducting the HPOP pressure test, you can ensure accurate results and minimize the risk of damage or injury. Taking the time to follow these steps will contribute to a successful testing process and help identify any potential issues with the high-pressure oil pump in your vehicle.

Step 2: Locate the HPOP Test Port

Before you can begin the HPOP pressure test, you need to locate the HPOP test port on your vehicle. The HPOP test port is where you will connect your pressure gauge to measure the pressure generated by the high-pressure oil pump. The location of the HPOP test port may vary depending on the make and model of your vehicle, so it is important to consult your vehicle’s service manual or online resources for specific instructions.

In most cases, the HPOP test port is located on the passenger side of the engine, near the high-pressure oil pump. It is typically a small, threaded port that allows you to connect your pressure gauge using a specialized adapter. The exact location and appearance of the HPOP test port may vary, so it is important to carefully inspect your engine to ensure that you have identified the correct port.

If you are having trouble locating the HPOP test port, it may be helpful to use a flashlight and a small mirror to look in hard-to-reach areas. Additionally, you can consult online forums or communities dedicated to your specific vehicle make and model for advice and guidance from other enthusiasts who have performed the HPOP pressure test.

Step 3: Connect the Pressure Gauge

Once you have prepared the HPOP system for testing, the next step is to connect the pressure gauge. The pressure gauge is a vital tool that will allow you to accurately measure the pressure within the system. This will help you determine if the HPOP is functioning properly or if there are any issues that need to be addressed.

Start by locating the HPOP pressure test port. This is usually located on the side of the HPOP cover or housing. Once you have found the port, remove any dust or debris to ensure a clean connection. Then, attach the pressure gauge to the test port using the appropriate fittings. Make sure the connections are secure to prevent any leaks during the test.

Before you start the pressure test, it is important to calibrate the pressure gauge to ensure accurate readings. You can do this by comparing the gauge reading to a known pressure source and adjusting it accordingly. Once the gauge is calibrated, you are ready to proceed with the HPOP pressure test.