When it comes to electrical grounding systems, safety and reliability are paramount. That’s why ERICO, a leader in the industry, has developed the groundbreaking Ground Test Well. This innovative solution offers a comprehensive approach to testing the effectiveness and integrity of grounding systems, ensuring that they meet the highest standards and regulations.

One of the key features of the ERICO Ground Test Well is its ability to accurately measure the resistance of the grounding system. By providing a low resistance path for electrical current to flow, the system ensures that the electrical equipment and the people working around it are protected from the potential dangers of electrical faults and surges.

Another notable aspect of the ERICO Ground Test Well is its versatility. It can be used in various applications, including industrial, commercial, and residential settings. Whether you’re working on a construction site, a power plant, or a residential building, the Ground Test Well offers a reliable and efficient method for testing the effectiveness of your grounding system.

Additionally, the ERICO Ground Test Well is designed with ease of use in mind. It features a user-friendly interface and clear instructions, making it accessible to both experienced professionals and those new to the field. With its intuitive design and advanced technology, the Ground Test Well simplifies the testing process and provides accurate results, saving time and resources.

In conclusion, the ERICO Ground Test Well is an essential tool for ensuring the safety and reliability of electrical grounding systems. With its accurate resistance measurement capabilities, versatility, and user-friendly design, it has become the go-to solution for professionals in the industry. By utilizing the Ground Test Well, you can have confidence in the integrity of your grounding system and the protection it provides.

What is a Ground Test Well Erico?

A ground test well Erico is a type of well that is specifically designed for testing the ground conditions before construction or other geotechnical projects. It is used to gather important data about the soil composition, groundwater levels, and other factors that can affect the stability and performance of structures.

Erico, a leading manufacturer of electrical grounding and bonding products, offers a range of ground test wells that are designed to provide accurate and reliable measurements. These wells are constructed using high-quality materials to ensure durability and long-term performance.

The ground test well Erico typically consists of a vertical shaft that is drilled or driven into the ground. It is equipped with sensors and instruments that can measure various parameters such as soil resistivity, moisture content, and temperature. These measurements help engineers and geotechnical professionals to better understand the characteristics of the soil and make informed decisions regarding foundation design, drainage systems, and other aspects of construction.

- Soil Resistivity: The ground test well Erico is capable of measuring the electrical resistivity of the soil, which is an important parameter for designing grounding and earthing systems. It helps determine the suitability of the soil for electrical grounding and can also provide insights into the corrosion potential of metallic structures.

- Moisture Content: By measuring the moisture content of the soil, the ground test well Erico can help assess the risk of soil settlement, erosion, and other potential issues. This information is crucial for designing effective drainage systems and preventing water-related damage to structures.

- Temperature: The ground test well Erico can also measure the temperature of the soil, which is important for understanding how it may expand or contract in response to seasonal and climatic changes. This information is essential for designing stable foundations and preventing damage caused by excessive soil movement.

In summary, a ground test well Erico is a specialized well used for gathering important data about soil conditions. It helps engineers and geotechnical professionals make informed decisions regarding construction and other geotechnical projects. With its accurate measurements and durable construction, the ground test well Erico is a valuable tool in ensuring the stability and performance of structures.

Importance of Ground Test Well Erico

Ground test well Erico is an essential tool in the field of geotechnical engineering. It provides crucial information about the soil properties and behavior, which is vital for the design and construction of various structures. By conducting tests on the ground using Erico, engineers can determine the suitability of a specific location for construction projects, such as buildings, bridges, and highways.

Accurate Data Collection: Ground test well Erico allows engineers to collect accurate data about the soil at different depths. This data helps in evaluating the soil’s mechanical properties, such as its strength, compressibility, and permeability. By understanding these properties, engineers can make informed decisions regarding site selection, foundation design, and the overall stability of the structure.

Design Optimization: Ground test well Erico plays a crucial role in optimizing the design of structures. With the data obtained from the tests, engineers can determine the appropriate foundation type and design parameters. They can also assess the potential risks associated with ground movement, such as settlement or slope instability, and take necessary precautions to prevent any failures or damages.

Cost-Effective Construction: Ground test well Erico helps in achieving cost-effective construction by providing accurate information about the soil conditions. This information enables engineers to optimize the design, choose suitable construction techniques, and select appropriate materials. By considering the specific soil properties, engineers can minimize the potential risks, avoid unnecessary foundation modifications, and reduce construction costs.

Ensuring Safety: The use of ground test well Erico is crucial for ensuring the safety of structures and occupants. By understanding the soil behavior, engineers can design foundations that can withstand the anticipated loads and environmental conditions. They can also identify any potential hazards, such as liquefaction or expansive soils, and implement appropriate mitigation measures to ensure the long-term stability and safety of the structure.

In conclusion, ground test well Erico plays a vital role in geotechnical engineering by providing accurate data about soil properties, optimizing the design, achieving cost-effective construction, and ensuring the safety of structures. Its importance cannot be underestimated as it significantly contributes to the success and longevity of construction projects.

Types of Ground Test Well Erico

The Ground Test Well Erico is an essential tool used in the construction industry to evaluate the subsurface conditions of a site. It is used to measure factors such as soil strength, permeability, and water table depth. There are several types of ground test well Erico available, each designed for specific purposes and applications.

1. Piezometers: Piezometers are used to measure groundwater levels and pressures in the soil. They consist of a small diameter casing, perforated at the bottom, and equipped with a filter to prevent soil particles from entering the well. The water level in the well is measured using a pressure transducer or a manual water level indicator. With piezometers, engineers can determine factors such as the hydraulic conductivity and pore water pressure of the soil.

2. Inclinometers: Inclinometers are used to measure the inclination or rotation of the ground. They are commonly used in slope stability analysis, tunneling, and deep excavation projects. Inclinometers consist of a casing installed vertically in the ground and equipped with sensors that measure the tilt or displacement of the casing. This data is then used to monitor ground movement and assess the stability of the surrounding soil.

3. Soil Sampling Wells: Soil sampling wells are used to collect soil samples for testing and analysis. They are typically installed to a depth of several meters and are equipped with a sampling device such as a split spoon sampler or a Shelby tube. The soil samples collected from these wells can provide valuable information about the composition, strength, and permeability of the soil, which is essential for designing foundations and assessing soil contamination.

4. Soil Moisture Measurement Wells: Soil moisture measurement wells are used to assess the moisture content of the soil. They are equipped with sensors that measure the electrical conductivity or capacitance of the soil, which is directly related to its moisture content. This information is crucial for irrigation planning, agricultural soil management, and assessing the potential for landslides and slope instability.

5. Geotechnical Instrumentation Wells: Geotechnical instrumentation wells are designed to accommodate various types of sensors and instruments used in geotechnical monitoring. They are installed at specific locations to measure parameters such as ground settlement, lateral deformation, pore pressure, and temperature. The data collected from these wells is used to assess the performance of structures, such as retaining walls and foundations, and to mitigate potential risks or failures.

In conclusion, the choice of ground test well Erico depends on the specific requirements of the project and the type of data that needs to be collected. Each type of well serves a unique purpose and provides valuable information for engineers and geotechnical specialists.

Components of Ground Test Well Erico

The ground test well Erico consists of several components that are essential for its functionality. These components work together to ensure accurate testing of ground conditions and groundwater analysis.

1. Well Casing: The well casing is a pipe that is inserted into the ground to provide structure and support to the well. It is typically made of durable materials such as PVC or steel. The well casing prevents the collapse of the wellbore and protects the groundwater from contamination.

2. Screen: The screen is a component that is attached to the bottom of the well casing. It allows groundwater to enter the well while preventing the entry of sediment and debris. The screen is usually made of stainless steel or PVC with small openings to filter out unwanted particles.

3. Pump: The pump is an essential component of the ground test well Erico as it is responsible for extracting groundwater from the well. It is typically a submersible pump that is placed inside the well casing. The pump is powered by electricity and is used to carry out various tests and analyses on the groundwater.

4. Monitoring Equipment: Ground test well Erico is equipped with various monitoring equipment to measure and record groundwater parameters. This may include sensors for measuring water level, temperature, pH, electrical conductivity, and other parameters. The monitoring equipment provides valuable data for assessing the quality and quantity of groundwater.

5. Control Panel: The control panel is the central unit that allows the operator to control and monitor the operation of the ground test well. It contains switches, gauges, and indicators to control pump operation, observe water levels, and monitor the performance of the equipment. The control panel ensures the safe and efficient operation of the ground test well.

Overall, the components of the ground test well Erico work together to provide accurate and reliable data on ground conditions and groundwater analysis. These components are designed to withstand the harsh conditions of the subsurface environment and provide essential information for various applications such as groundwater management, environmental monitoring, and geotechnical engineering.

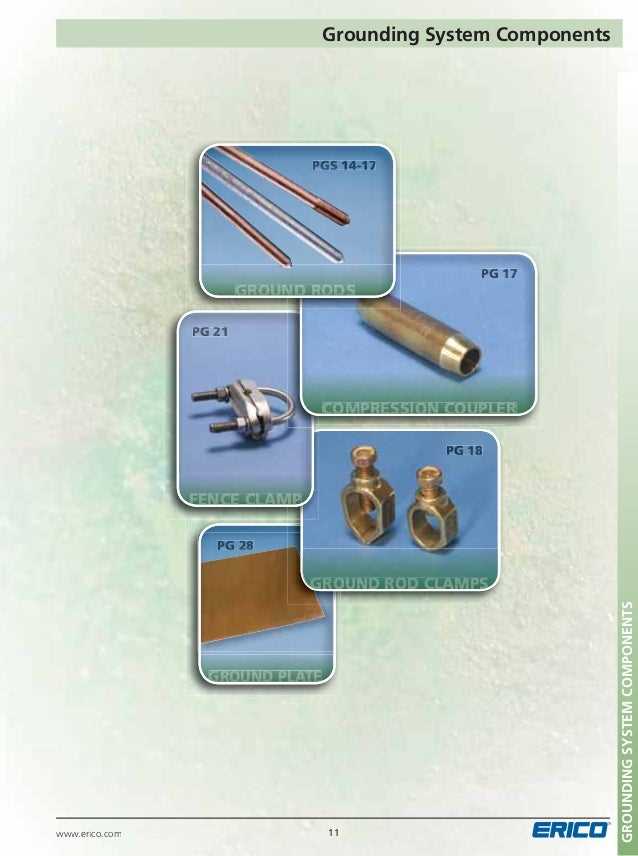

Ground Rod

A ground rod, also known as an earthing rod, is a long cylindrical metal rod that is used to connect electrical systems to the ground. It is an essential component of grounding systems, which are designed to protect electrical equipment, buildings, and individuals from the dangers of electrical faults.

Ground rods are typically made of copper or galvanized steel, and they are buried vertically in the ground. The metal rod provides a low-resistance path for electrical current to flow into the earth, which helps to prevent the buildup of electrical charges and reduces the risk of electric shock or damage to equipment.

A ground rod is usually installed near the building or structure that it is intended to protect. It is connected to the grounding system through a conductor, such as a copper wire, which ensures a continuous path for the current to flow. The rod is driven into the ground using specialized equipment, such as a ground rod driver, and it should be buried at least 8 feet deep to ensure proper grounding.

Ground rods are commonly used in various industries, including telecommunications, power distribution, and construction. They are an important part of the grounding system of electrical substations, cell towers, and residential buildings. Regular maintenance of ground rods, including testing for resistance and corrosion, is essential to ensure their effectiveness in providing a safe electrical environment.

Grounding Clamp

The grounding clamp is an essential component used in electrical grounding systems. It is designed to securely connect the conductor with the grounding electrode, providing a low-resistance path for electrical current to flow into the earth. The clamp is typically made of high-quality materials such as copper or bronze, which offer excellent conductivity and corrosion resistance.

One of the key features of a grounding clamp is its ability to provide a reliable and long-lasting connection. The clamp is designed to tightly grip the conductor, ensuring a low-resistance connection that can withstand various environmental conditions, including moisture, temperature fluctuations, and mechanical stress. This ensures the effectiveness and safety of the grounding system.

A grounding clamp typically consists of two parts – the clamp body and the connector. The clamp body is responsible for securely holding the conductor, while the connector provides the interface between the clamp and the grounding electrode. The connector may vary depending on the specific application and the type of grounding electrode being used.

There are different types of grounding clamps available, such as mechanical clamps, compression clamps, and exothermic welding clamps. Each type has its own advantages and is suitable for different applications. Mechanical clamps, for example, are easy to install and can be adjusted for different conductor sizes. Compression clamps, on the other hand, provide a higher level of conductivity and are commonly used in high-current applications.

In conclusion, the grounding clamp is an essential component in electrical grounding systems, providing a secure and reliable connection between the conductor and the grounding electrode. It plays a vital role in ensuring the safety and effectiveness of the grounding system, and there are different types of clamps available to suit various applications.