When it comes to testing the strength and performance of materials, engineers and scientists rely on a variety of experiments. One such experiment is Hopkinson’s test, a widely used method for characterizing the mechanical properties of materials under high strain rates. This test, named after British engineer Bertram Hopkinson, is essential in understanding how materials behave under dynamic loading conditions.

At its core, Hopkinson’s test involves subjecting a specimen to high-speed impact loading using a striker bar and incident bar. The striker bar, typically made of steel, is launched towards the incident bar, which is connected to the specimen. As the striker bar collides with the incident bar, a stress wave is generated, propagating through the incident bar and into the specimen. This wave creates significant deformations and strain rates, enabling researchers to study the material’s response to dynamic loading.

Hopkinson’s test is particularly useful in studying materials that exhibit different behavior under static and dynamic loading conditions. By subjecting a material to high strain rates, scientists can determine its dynamic response, including factors such as elastic modulus, yield strength, and fracture toughness. This information is crucial for applications where materials experience impact or rapid loading, such as in automotive components, aerospace structures, or protective gear.

Over the years, Hopkinson’s test has evolved, giving rise to variations such as the Split Hopkinson Pressure Bar (SHPB) test, specifically designed for studying compressive behavior. Additionally, advancements in computational modeling techniques have allowed for more accurate predictions and analysis of the test results. This combination of experimental and computational approaches has significantly contributed to our understanding of material behavior at high strain rates, paving the way for the development of innovative and safer designs in various industries.

Hopkinsons Test: Everything You Need to Know

The Hopkinson’s test is a commonly used test to determine the performance of electrical machines such as electric motors and generators. It is conducted to assess the efficiency, power output, and overall functionality of these machines. In this test, the machine is run as a motor and connected to a dynamometer, which acts as a brake to measure the torque and speed of the machine.

Procedure: The Hopkinson’s test involves a few key steps. First, the machine under test is connected to the dynamometer, which acts as a mechanical load. The machine is then started and brought up to a specific speed. The output power and speed are measured, and the torque is calculated using the measured values. This information is crucial in determining the efficiency and performance of the machine.

The test is particularly useful in determining the losses in electrical machines. By measuring the input and output power, it is possible to calculate the losses due to electrical, mechanical, and magnetic factors. These losses can then be used to assess the overall efficiency of the machine and identify areas for improvement.

One of the advantages of the Hopkinson’s test is its ability to provide accurate and reliable results. It allows engineers and technicians to assess the performance of the machine under real operating conditions. This information can then be used to optimize the design and operation of electrical machines and improve overall efficiency.

Overall, the Hopkinson’s test is an essential tool in the field of electrical machines. Its ability to accurately measure power output, torque, and efficiency makes it a valuable test in the design and development process. By conducting this test, engineers and technicians can ensure that electrical machines are operating optimally and identify any areas for improvement.

What Is Hopkinsons Test?

Hopkinsons test, also known as the synchronous motor test or the generator excitation test, is a common diagnostic test conducted on generators. This test helps to determine the condition and performance of a generator’s excitation system, which is responsible for providing the necessary direct current (DC) to the generator’s field winding.

The Hopkinsons test involves running the generator at synchronous speed while gradually increasing the excitation current. This allows engineers to observe and analyze various parameters, such as voltage, current, and power factor, to assess the generator’s performance and identify any potential issues. The test is typically performed during maintenance or troubleshooting activities to ensure the generator is operating correctly.

The procedure for conducting a Hopkinsons test typically involves the following steps:

- Preparing the generator for the test by ensuring all safety measures are in place and that the generator is disconnected from the power grid.

- Gradually increasing the excitation current while monitoring and recording the generator’s voltage, current, and power factor readings.

- Observing the generator’s response to the increased excitation current, such as any changes in voltage or power factor.

- Analyzing the recorded data to evaluate the generator’s performance and identify any abnormalities or deviations from expected values.

- Based on the analysis, determining if any corrective actions are necessary, such as adjusting the excitation system or addressing any identified issues or faults.

In summary, Hopkinsons test is a diagnostic test conducted on generators to assess the performance of their excitation system. By conducting this test, engineers can ensure the generator is operating efficiently and identify any potential issues that may require maintenance or repairs.

How Does Hopkinsons Test Work?

Hopkinsons test is a method used to determine the performance characteristics of a steam turbine. It involves running the turbine at various loads and measuring parameters such as power output, steam flow rate, and steam temperature. This test is typically carried out during the commissioning phase of a new turbine or after major maintenance work to ensure that the turbine is operating within the specified design parameters.

In order to conduct a Hopkinsons test, the turbine is connected to a generator and the steam supply is gradually increased. The test starts at a low load and the turbine is brought up to its full capacity in several steps. At each load level, measurements are taken to determine the turbine’s performance, including its efficiency and power output.

A key aspect of the Hopkinsons test is the measurement of steam flow rate. This is typically done using flow meters installed in the steam supply line. These flow meters provide accurate measurements of the amount of steam entering the turbine, which is crucial for evaluating its performance.

Another important parameter to measure during the Hopkinsons test is steam temperature. This is typically done using temperature sensors placed at different points in the steam path, such as at the inlet and outlet of the turbine. By measuring the temperature difference between these points, it is possible to assess the efficiency of the turbine.

Overall, the Hopkinsons test is a valuable tool for assessing the performance of steam turbines and ensuring they are operating optimally. By measuring parameters such as power output, steam flow rate, and steam temperature, engineers can gain valuable insights into the turbine’s efficiency and make any necessary adjustments to improve its performance.

The Importance of Hopkinson’s Test

Hopkinson’s test, also known as the back-to-back test or synchronous generator test, is a crucial method used to determine the performance and efficiency of electric machines and power systems. This test is commonly used in the field of electrical engineering to evaluate the power performance and dynamic characteristics of electrical devices such as generators, transformers, motors, and high-voltage circuit breakers.

Accurate Performance Assessment: Hopkinson’s test provides valuable insights into the performance of electrical machines by allowing engineers to measure parameters such as efficiency, power factor, and total harmonic distortion. By subjecting the machine to realistic operating conditions, engineers can obtain precise data on its performance, which is crucial for design improvements and ensuring optimum efficiency.

Validation of Design: Conducting Hopkinson’s test is essential for verifying the design of electrical machines and power systems. By measuring various electrical and mechanical parameters under load, engineers can assess if the machine is functioning as intended and if it meets the required specifications. This test helps identify any design flaws or manufacturing defects that may affect the machine’s performance or reliability, allowing for necessary adjustments or improvements.

Monitoring Equipment Health: Hopkinson’s test is a valuable tool for monitoring the health and condition of electrical machines over time. By periodically conducting this test, engineers can assess any changes in the machine’s performance and detect any signs of degradation or malfunction. This allows for proactive maintenance and repairs, preventing costly breakdowns or unexpected failures.

Industry Standard: Hopkinson’s test is widely recognized and accepted as a standard method in the field of electrical engineering. It provides consistent and reliable data that can be used for comparisons between different machines or for benchmarking purposes. The test procedure is well-documented, ensuring reproducibility and allowing for accurate assessments across different laboratories and research institutions.

In conclusion, Hopkinson’s test plays a vital role in the design, evaluation, and maintenance of electrical machines and power systems. By providing accurate performance assessment, validating design, monitoring equipment health, and serving as an industry standard, this test helps ensure the efficiency, reliability, and optimal functioning of electrical devices in various applications.

Procedure for Conducting Hopkinsons Test

The Hopkinsons test is a commonly used procedure to evaluate the performance and efficiency of large-scale power transformers. It helps determine the ability of the transformer to handle overloads and short circuits. This test is conducted in a controlled environment to ensure the safety of the operators and the equipment.

Preparation: Before conducting the Hopkinsons test, the transformer is thoroughly inspected for any physical damage or defects. All necessary safety precautions are taken, and the test setup is prepared. This includes connecting the necessary equipment, such as the power supply, measuring devices, and protective devices.

Test setup: The transformer is carefully connected to a power supply, which can be an AC or DC source depending on the test requirements. The necessary protective devices, such as fuses and circuit breakers, are also installed to ensure the safety of the operator and prevent any damage to the equipment in case of any abnormality during the test.

Test procedure: Once the test setup is complete, the transformer is subjected to a series of electrical conditions, including overloads and short circuits, to evaluate its performance under different scenarios. The power supply is adjusted to simulate various load conditions, and the performance of the transformer is measured using appropriate measuring devices, such as voltage and current meters.

Monitoring and analysis: During the test, the operator closely monitors the transformer’s performance, recording the data obtained from the measuring devices. This data is then analyzed to evaluate factors such as voltage drop, temperature rise, and efficiency. Any abnormalities or deviations from the expected performance are noted and investigated further.

Post-test procedures: Once the test is completed, the transformer is carefully disconnected from the power supply, and all the equipment is properly shut down. The collected data is analyzed in detail to assess the transformer’s performance and identify any necessary adjustments or repairs that may be required.

In conclusion, the Hopkinsons test is an essential procedure for evaluating the performance of power transformers. By simulating various electrical conditions, it helps ensure the safe and efficient operation of transformers in real-world scenarios.

Parameters Tested in Hopkinsons Test

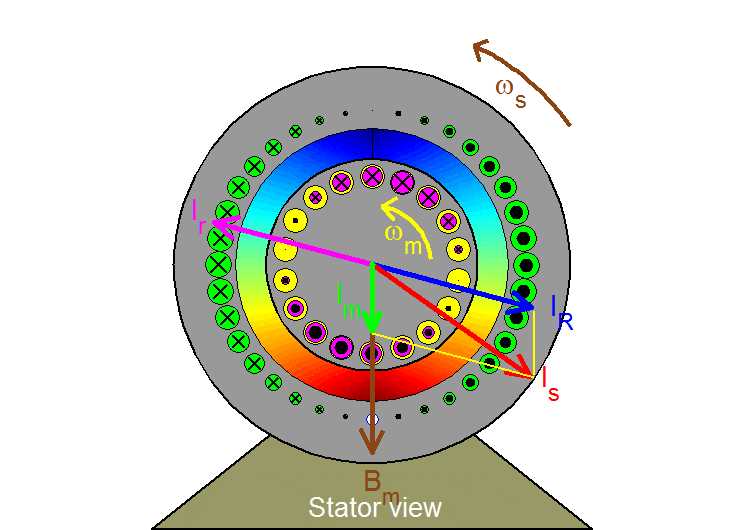

Hopkinsons test is a type of electrical test conducted on synchronous generators to determine their load performance and stability. This test involves applying a mechanical load to the generator and measuring various parameters to assess its performance. Some of the key parameters tested in the Hopkinsons test include:

Rotor Speed:

During the Hopkinsons test, the speed of the rotor is measured under different load conditions. This parameter helps evaluate the response of the generator to varying mechanical loads and determines its ability to maintain a stable rotational speed.

Stator Current:

The stator current is another important parameter that is measured during the Hopkinsons test. It helps determine the electrical output of the generator under different load conditions. By analyzing the stator current, engineers can assess the generator’s ability to deliver power efficiently and reliably.

Voltage Regulation:

The voltage regulation of a generator refers to its ability to maintain a relatively stable output voltage under varying load conditions. In the Hopkinsons test, the voltage regulation is tested by applying different mechanical loads and measuring the corresponding changes in the generator’s output voltage. This parameter gives insights into the generator’s voltage control capabilities.

Excitation System Response:

The excitation system of a generator is responsible for controlling the field current, which in turn influences the generator’s electrical output. The Hopkinsons test assesses the excitation system response by monitoring the changes in the field current under different load conditions. This parameter helps evaluate the generator’s ability to regulate its output and maintain stability.

Efficiency:

The efficiency of a generator is an important parameter that determines its overall performance and cost-effectiveness. During the Hopkinsons test, the input power and output power of the generator are measured to calculate its efficiency. This parameter provides valuable information about the generator’s energy conversion capabilities and can help optimize its operation.

Overall, the Hopkinsons test plays a crucial role in evaluating the performance and stability of synchronous generators. By testing parameters such as rotor speed, stator current, voltage regulation, excitation system response, and efficiency, engineers can identify any issues or inefficiencies in the generator and make the necessary adjustments for optimal performance.