When it comes to evaluating the durability of products, one of the most important tests is the Ista 3a drop test. This standardized test is designed to simulate the impact a package or product may experience during shipping or handling. By subjecting products to controlled drops from various heights and angles, manufacturers can assess their ability to withstand potential accidents and ensure their safe arrival to the end consumer.

The Ista 3a drop test involves dropping a package or product onto a hard surface, such as concrete or wood, from heights ranging from a few inches to several feet. The test is performed multiple times, with drops from different orientations and angles. The objective of the test is to evaluate the product’s ability to withstand the impact without damage, as well as its ability to protect its contents.

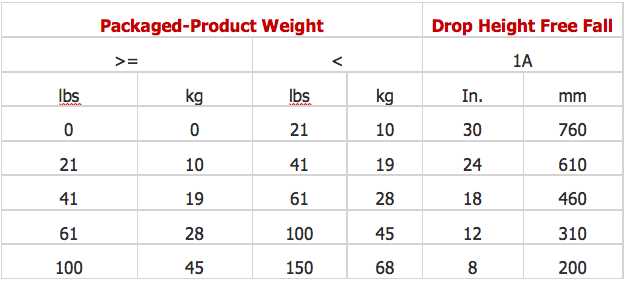

During the Ista 3a drop test, various parameters are taken into account, such as the weight and size of the product, the type of packaging, and the drop height. These parameters are carefully chosen to mimic real-world scenarios and to ensure that the test accurately represents the challenges that the product may face during transportation and handling.

By conducting the Ista 3a drop test, manufacturers can identify any weak points in their product design or packaging and make necessary adjustments to improve their durability and resilience. This test provides valuable insights into the product’s ability to withstand the rigors of transportation and can help prevent potential damage or loss during shipping.

Ista 3a Drop Test Explained: Everything You Need to Know

The Ista 3a drop test is a standardized testing procedure that is used to evaluate the ability of packaging materials and containers to withstand drops from a specified height. It is commonly used in industries such as shipping, automotive, and electronics to ensure that their products are protected during transportation.

During an Ista 3a drop test, the test specimen is placed onto a rigid surface and dropped from a specified height. The drop height can vary depending on the requirements of the test, but it is typically between 30 and 150 cm. The package is dropped in different orientations, including flat, edge, and corner drops, to simulate different real-world scenarios.

The purpose of the Ista 3a drop test is to:

- Evaluate the effectiveness of the packaging design in protecting the product inside

- Identify weak points or areas of vulnerability in the packaging

- Determine if any modifications or improvements need to be made to the packaging

- Ensure compliance with industry standards and regulations

During the drop test, the package is inspected for any damage or failure, such as cracks, breaks, or deformations. The product inside the package is also examined to determine if it has been damaged or affected in any way. The test results are then analyzed to determine the packaging’s ability to withstand drops and protect the product.

In conclusion, the Ista 3a drop test is an essential procedure for evaluating the durability and effectiveness of packaging materials and containers. By subjecting packages to simulated drops, manufacturers can ensure that their products will arrive safely to consumers, minimizing the risk of damage during transportation.

What is Ista 3a Drop Test?

Ista 3a Drop Test is a standardized testing procedure used to evaluate the packaging design and durability of a product. It is conducted by subjecting the packaged product to a series of drops from specified heights and angles, simulating the impacts it may experience during transportation and handling.

The purpose of the Ista 3a Drop Test is to assess the ability of the packaging to protect the product from potential damage and ensure its safe arrival at the destination. The test helps identify potential weaknesses in the packaging design and provides valuable data for improvements and optimizations.

The Ista 3a Drop Test follows a specific protocol established by the International Safe Transit Association (Ista). It defines the drop heights, orientations, and package orientations to be used during the testing. The test can be performed using various drop testing machines, which can replicate different types of drops, such as freefall drops, rotational drops, or inclined plane drops.

During the Ista 3a Drop Test, the packaged product is dropped multiple times from different angles and heights, with a predetermined number of drops required to be performed. The drops can be repeated until a failure threshold is reached or until the required number of drops is completed.

The test results are measured and evaluated based on predefined criteria, such as the product’s functionality, structural integrity, and visual appearance after each drop. Any damage or failure observed during the test is recorded and analyzed to determine if the packaging meets the required standards and specifications.

The Importance of Ista 3a Drop Test for the Packaging Industry

In the packaging industry, ensuring the safety and durability of products during transportation is of utmost importance. This is where the Ista 3a drop test plays a crucial role. The Ista 3a drop test is a standardized testing procedure that evaluates the ability of packaging to protect its contents from damage when dropped from a certain height. This test is essential for manufacturers and suppliers as it helps them understand the strength and effectiveness of their packaging designs in real-world scenarios.

One of the key reasons why the Ista 3a drop test is important is that it helps identify potential weaknesses in packaging materials and design. By subjecting packages to simulated dropping conditions, manufacturers can assess whether the package can withstand the impact and adequately protect the product inside. This allows them to make necessary modifications and improvements to ensure that the packaging can withstand the rigors of transportation and prevent damage to the product. This ultimately saves both time and money by reducing the risk of product loss or rejection due to packaging failures.

- Validation of packaging design: The Ista 3a drop test provides a reliable method for validating the design and performance of packaging. By conducting this test, manufacturers can determine if their packaging design meets the required industry standards and specifications. This helps ensure that the package can withstand the potential hazards during transportation and delivery.

- Enhanced product protection: The Ista 3a drop test helps manufacturers and suppliers evaluate the impact resistance of their packaging. By identifying weak points and areas that need improvement, they can enhance the protective qualities of their packaging, reducing the risk of damage to the product during handling and shipping.

- Improved customer satisfaction: Proper packaging is vital for maintaining customer satisfaction. By subjecting packaging to the Ista 3a drop test, manufacturers can ensure that their products arrive intact and in optimal condition, minimizing the likelihood of customer complaints or returns due to damaged goods.

- Compliance with regulations: The Ista 3a drop test helps manufacturers and suppliers comply with industry regulations and standards. By conducting this test, they can ensure that their packaging meets the required performance criteria, reducing the risk of legal issues and penalties.

In conclusion, the Ista 3a drop test plays a critical role in the packaging industry by evaluating the strength and effectiveness of packaging designs. By conducting this standardized test, manufacturers and suppliers can identify weaknesses, enhance product protection, improve customer satisfaction, and ensure compliance with regulations. Investing in proper packaging testing can ultimately lead to cost savings and a stronger reputation in the market, making it an essential component of any packaging industry operation.

Understanding the Testing Procedure

The Ista 3a drop test is a critical part of the packaging design process. This test is designed to simulate the different types of drops that a package may encounter during its transportation and handling. By subjecting the package to controlled drops, the test helps assess its ability to withstand the impact and protect the product inside. It is an essential step in ensuring that the packaging meets the required standards and provides adequate protection for the product.

The testing procedure involves dropping the package from different heights and orientations to replicate real-life scenarios. The package is dropped onto different surfaces, including edges and corners, to assess its resistance to impact from various angles. The drop test is conducted using specialized equipment that ensures accurate and consistent results. The parameters such as drop height, drop orientation, and surface type are carefully controlled to provide reliable data for evaluation.

The Ista 3a drop test procedure typically consists of the following steps:

- Preparation: The packaging is inspected and prepared according to the test requirements. It is essential to ensure that the product is properly positioned within the package to accurately assess its protective capabilities.

- Drop sequence: The package is dropped multiple times from different heights and orientations, as specified by the test protocol. The drops are performed in a controlled manner to ensure consistent and repeatable results.

- Assessment: After each drop, the package is examined for any visible damage. The test evaluates parameters such as the integrity of the package, the functionality of closures and seals, and the condition of the product inside.

- Analysis: The test results are analyzed to determine the package’s ability to withstand drops and protect the product. This analysis helps identify any design or material deficiencies that need to be addressed.

The Ista 3a drop test is an important tool in assessing the reliability and durability of packaging. It allows manufacturers to make informed decisions regarding the design and materials used in their packaging, ultimately ensuring the safe transportation and delivery of their products.

Types of Packaged Products that Undergo ISTA 3A Drop Test

ISTA 3A Drop Test is a widely recognized standard for testing the durability and stability of packaged products. It simulates the potential hazards that a package may encounter during handling, transportation, and distribution. Many different types of products undergo the ISTA 3A Drop Test to ensure their safe and secure delivery to customers.

1. Electronic Devices: Electronic devices such as smartphones, tablets, laptops, and other consumer electronics often undergo the ISTA 3A Drop Test. These products are vulnerable to impact and vibration during shipping, and the test helps manufacturers identify potential weaknesses and make improvements in their packaging.

2. Glassware and Ceramics: Fragile items like glassware and ceramics are prone to breakage during transportation. The ISTA 3A Drop Test allows manufacturers to evaluate the packaging design and materials used to protect these delicate products. It helps ensure that they arrive in perfect condition, minimizing the risk of damage.

3. Automotive Parts: Automotive parts, such as engine components, transmissions, and braking systems, need to withstand rigorous handling and potential drops during transportation. By subjecting these parts to the ISTA 3A Drop Test, manufacturers can assess the effectiveness of their packaging in protecting these critical components.

4. Pharmaceutical and Medical Products: Pharmaceuticals and medical products, including vials, syringes, and medical devices, undergo the ISTA 3A Drop Test to ensure their integrity and safety. This testing helps manufacturers identify weaknesses in packaging materials and design that could compromise the sterility and quality of these products.

5. Consumer Goods: Various consumer goods like cosmetics, food products, and household items are also subjected to the ISTA 3A Drop Test. This test helps ensure that the packaging can withstand drops and impacts commonly encountered during transportation, preventing damage to the products inside.

- Other product categories that often undergo ISTA 3A Drop Test include:

- Furniture and Home Appliances

- Industrial Equipment and Machinery

- Toys and Sporting Goods

- Electrical and Plumbing Supplies

In conclusion, the ISTA 3A Drop Test is a crucial evaluation method for a wide range of packaged products. It helps manufacturers identify potential weaknesses in packaging design and materials, allowing them to make necessary improvements and ensure the safe delivery of their products to customers.

Benefits of Conducting Ista 3a Drop Test

Conducting an Ista 3a drop test on a product can provide several benefits for manufacturers, retailers, and customers alike. This type of test is designed to simulate the impact a product may experience during handling, shipping, or storage, ensuring that it can withstand the rigors of the distribution process. By subjecting products to controlled drops, manufacturers can identify potential weaknesses and make necessary improvements to ensure product integrity and customer satisfaction.

1. Improved Product Quality: The Ista 3a drop test allows manufacturers to assess the durability of their products and identify any design flaws or weaknesses. By making improvements based on the test results, manufacturers can enhance the overall quality and reliability of their products, reducing the risk of damage during transportation or use.

2. Cost Savings: Conducting an Ista 3a drop test can help manufacturers identify potential issues before the product reaches the market. By addressing these issues early on, manufacturers can minimize product returns, repairs, and replacements, resulting in significant cost savings. Additionally, avoiding product damage during shipping can also reduce insurance claims and associated costs.

3. Customer Satisfaction: Ensuring that products can withstand drops and other hazards during transportation is crucial for customer satisfaction. By conducting Ista 3a drop tests, manufacturers can provide their customers with products that are more durable and reliable, minimizing the risk of damage and increasing customer confidence in the brand.

4. Compliance with Industry Standards: Many industries have specific packaging and handling requirements to ensure product safety and integrity. Conducting Ista 3a drop tests allows manufacturers to demonstrate compliance with these industry standards, providing assurance to retailers and customers that the product has undergone rigorous testing to meet or exceed the required criteria.

In conclusion, conducting an Ista 3a drop test can bring numerous benefits to manufacturers, including improved product quality, cost savings, increased customer satisfaction, and compliance with industry standards. By investing in drop testing, manufacturers can enhance the reliability and durability of their products, ultimately providing greater value to their customers.