Standpipe systems are an essential part of fire protection in buildings, providing a means for firefighters to access water on multiple floors. To ensure the reliability and effectiveness of these systems, regular testing and maintenance is required. The National Fire Protection Association (NFPA) has established guidelines for standpipe testing in NFPA 14, Standard for the Installation of Standpipe and Hose Systems.

Standpipe testing involves a series of checks, inspections, and procedures to verify that the system is in proper working order. This includes testing the water supply, pressure gauges, valves, and hose connections. The aim is to identify any potential issues or deficiencies that could hinder the system’s ability to deliver adequate water during a fire emergency.

NFPA 14 outlines the frequency and requirements for different types of standpipe testing. It specifies the minimum pressures and flow rates that must be achieved during the tests, as well as the procedures for documenting the results. Regular testing not only ensures compliance with NFPA standards but also helps to prolong the life of standpipe systems and enhance their overall performance.

NFPA 14 Standpipe Testing: Ensure Fire Safety Compliance

Standpipe systems are an essential component of fire safety in buildings. They provide a reliable water supply for firefighters to combat fires quickly and efficiently. To ensure the proper functioning of standpipe systems, it is crucial to conduct regular testing and inspections in compliance with NFPA 14 standards.

NFPA 14, titled “Standard for the Installation of Standpipe and Hose Systems,” outlines the requirements for the design, installation, maintenance, and testing of standpipe systems. It encompasses various types of standpipe systems, including Class I, Class II, and Class III standpipes. Compliance with NFPA 14 ensures that standpipe systems meet the necessary standards for fire safety in buildings.

Regular testing and inspections are essential to verify the operational integrity of standpipe systems. NFPA 14 provides guidelines for the frequency and methods of testing and inspection. These include flow testing, pressure testing, and checking for obstructions or impairments within the system.

During flow testing, water is discharged from the standpipe system to measure the water flow rate and pressure at various points. This ensures that an adequate water supply is available to firefighters during an emergency. Pressure testing verifies the system’s ability to withstand the required pressure levels without leakage or failure.

Checking for obstructions or impairments within the system is also crucial to guarantee its functionality. This involves examining standpipe valves, outlets, hose connections, and any other components for blockages, damage, or defects that may hinder water flow or compromise the system’s effectiveness.

Compliance with NFPA 14 standards for standpipe testing helps to ensure that standpipe systems are reliable and readily available in the event of a fire. It increases the chances of successful fire suppression and protection of life and property.

Building owners, facility managers, and fire safety professionals should prioritize scheduling regular standpipe testing and inspections to comply with NFPA 14 standards. By doing so, they demonstrate their commitment to fire safety and contribute to creating a safer environment for occupants and emergency responders.

Overview of Nfpa 14 Standard

The NFPA 14 Standard for the Installation of Standpipe and Hose Systems provides requirements for the design, installation, and testing of standpipe systems in order to ensure their effectiveness in fire protection. Standpipe systems are crucial components of buildings, as they provide a reliable source of water for firefighters to suppress fires in high-rise buildings, large structures, and other occupancies.

The standard covers various aspects of standpipe systems, including their types, components, location, and arrangement. It specifies the requirements for water supply, such as the minimum water pressure and flow rate, as well as the types of water sources that can be used. The standard also addresses the installation of valves, fire department connections, and other necessary devices and equipment.

Types of Standpipe Systems:

- Class I standpipe systems: These systems are intended for use by fire departments and equipped with 2.5-inch hose connections installed to supply water for fire suppression on the exterior of the building.

- Class II standpipe systems: These systems are intended for use by building occupants and equipped with 1.5-inch hose connections installed to supply water for fire suppression on the interior of the building.

- Class III standpipe systems: These systems are a combination of Class I and Class II systems and provide both options for fire department and building occupant use.

Testing Requirements:

The NFPA 14 standard also outlines the testing requirements for standpipe systems to ensure their proper functioning. These tests include hydrostatic pressure tests, flow tests, and operational tests. Hydrostatic pressure tests involve pressurizing the system to verify its structural integrity, while flow tests determine the water flow rate and pressure available at designated hose connections. Operational tests assess the functionality of components such as valves, fire department connections, and alarms.

Compliance with the NFPA 14 standard is crucial for the safety of occupants and the effectiveness of firefighting operations. By adhering to these requirements, building owners, designers, contractors, and regulatory authorities can ensure that standpipe systems are installed and maintained properly, providing reliable fire protection capabilities.

Importance of Standpipe Testing

Standpipe systems play a crucial role in providing a reliable water supply for fire fighting in buildings. As such, it is essential to regularly test and maintain these systems to ensure their proper functioning. Compliance with NFPA 14 standards for standpipe testing is necessary to meet fire safety requirements and protect the occupants of the building as well as the surrounding properties.

Regular testing of standpipe systems allows for the identification and rectification of any issues or malfunctions. By conducting periodic flow tests, pressure tests, and visual inspections, potential problems can be detected early on, preventing failures during an actual emergency. These tests help ensure that standpipe systems are capable of delivering the required water flow and pressure to firefighting personnel in a timely manner.

Flow tests are performed to measure the actual water flow rate at various points throughout the standpipe system. This is important because it allows fire departments to determine if the system can meet the demands of different fire suppression operations. Pressure tests, on the other hand, help evaluate the overall condition of the system, including the integrity of the pipes, valves, and other components.

By regularly testing and inspecting standpipe systems, potential issues like blockages, leaks, and valve failures can be identified and addressed promptly. This proactive approach helps prevent potentially catastrophic consequences and ensures that the standpipe system is ready for use in emergency situations. It is crucial to adhere to NFPA 14 standards for standpipe testing to maintain the reliability and effectiveness of these vital fire protection systems.

In conclusion, standpipe testing is of utmost importance to ensure that these systems are functioning properly and can provide the necessary water supply for fire fighting. Regular testing and inspection help detect and address any issues early on, preventing failures during emergencies. Compliance with NFPA 14 standards is essential for maintaining the reliability and effectiveness of standpipe systems.

NFPA 14 Standpipe Testing Requirements

Standpipes are an essential component of fire protection systems in buildings. NFPA 14 provides comprehensive guidelines for the installation, testing, and maintenance of standpipes to ensure their proper functioning in case of fire emergencies. Testing of standpipes is a critical aspect of maintaining their reliability and effectiveness.

According to NFPA 14, standpipes must undergo various testing requirements to ensure their compliance with safety standards. These tests include but are not limited to hydrostatic pressure tests, flow tests, and hose valve tests. The purpose of these tests is to verify that the standpipe system can handle the required water pressure and flow rates, as well as to identify any potential issues or malfunctions.

Hydrostatic pressure tests involve filling the standpipe system with water and pressurizing it to a certain level for a specified amount of time. This test is conducted to evaluate the structural integrity of the system, including pipes, valves, and fittings. It is crucial to detect any leaks, weak points, or potential failures that may compromise the system’s functionality in a real fire situation.

Flow tests are performed to measure the actual water flow rates that the standpipe system can deliver. These tests are carried out at specific hose connections or standpipe outlets, and the flow rates are recorded to ensure they meet the required standards. Flow tests help determine if there are any blockages, restrictions, or inadequate water supply that could hinder firefighting efforts.

Hose valve tests evaluate the performance of the hose valves installed on the standpipe system. These tests involve opening and closing the valves while under pressure to ensure they operate smoothly and effectively. The valves should provide a reliable means of controlling the water supply to the standpipe system and allow for easy connection and operation of fire hoses.

Overall, NFPA 14 standpipe testing requirements aim to guarantee that these fire protection systems are in optimal condition and ready to be utilized during a fire event. Regular testing and maintenance are essential to identify and address any issues promptly, ensuring the safety of building occupants and firefighters.

Testing Frequency and Inspection Intervals

According to NFPA 14 (Standard for the Installation of Standpipe and Hose Systems), standpipe systems need to be tested and inspected at regular intervals to ensure their proper functioning. These tests and inspections are crucial in identifying any potential issues or deficiencies that could affect the system’s performance in an emergency.

Testing Frequency: NFPA 14 recommends that standpipe systems should be tested annually. This testing should include flowing water through the system to assess its water supply capabilities and ensure that the correct pressure and flow rates are achieved. These tests help confirm that the system can provide adequate water for firefighting purposes.

In addition to annual testing, certain components of the standpipe system may require more frequent testing. For example, valves and pressure gauges should be inspected monthly to verify their proper operation and accuracy. This frequent inspection allows for timely repair or replacement of any faulty components.

Inspection Intervals: NFPA 14 also outlines inspection intervals for standpipe systems. These inspections should be conducted at least every 5 years and aim to identify potential construction or system alterations that may have occurred since the last inspection. During these inspections, all components of the standpipe system should be examined, including pipes, hoses, valves, and fittings, to ensure their integrity and compliance with the installation standards.

Additionally, property owners or building managers should also perform regular visual inspections of the standpipe system to look for obvious signs of damage or wear. This simple inspection can help identify any immediate concerns that may require immediate attention.

To maintain compliance with NFPA 14 and ensure the reliability of the standpipe system, it is crucial to adhere to the recommended testing frequency and inspection intervals. Regular testing and inspections help ensure that the standpipe system is functioning properly and can effectively support firefighting efforts in the event of an emergency.

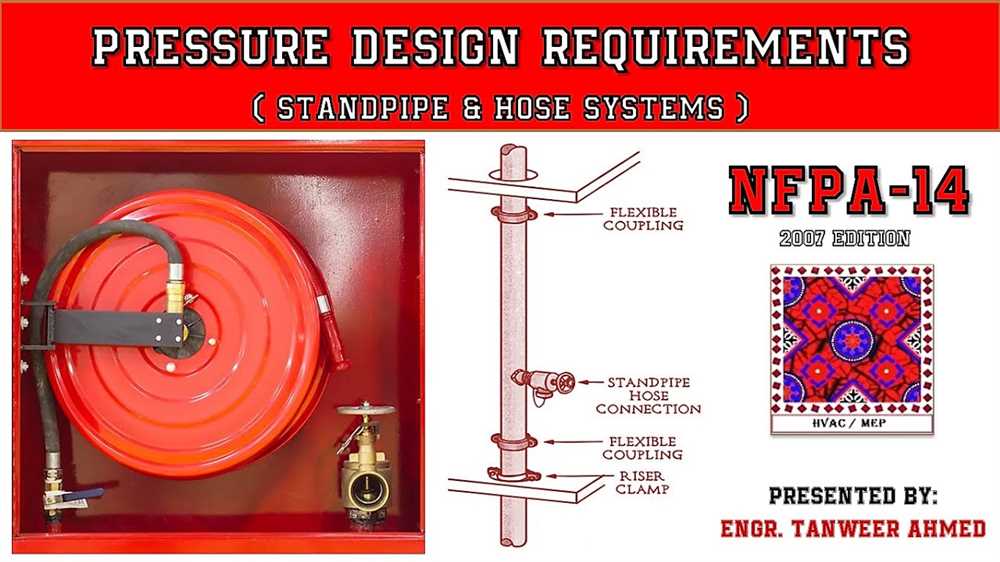

Standpipe System Components and Inspection Points

A standpipe system is a critical component of a building’s fire protection system. It is designed to provide a water supply for firefighters to use in the event of a fire. The system consists of various components that must be inspected regularly to ensure they are functioning properly.

Standpipe outlets: These are the points where firefighters can connect their hoses to the standpipe system. It is important to inspect these outlets regularly to ensure they are not damaged or obstructed. Any obstructions should be removed, and any damaged outlets should be repaired or replaced.

Standpipe valves: The standpipe valves control the flow of water through the system. Regular inspections should be conducted to make sure these valves are in working order and can be easily operated. The valves should be checked for any leaks or signs of corrosion, and any faulty valves should be repaired or replaced.

Pressure gauges: Pressure gauges are used to monitor the water pressure in the standpipe system. These gauges should be inspected regularly to ensure they are accurate and functioning properly. Any faulty or inaccurate gauges should be replaced.

Fire department connections: These connections allow firefighters to easily access the standpipe system and connect their hoses. Fire department connections should be inspected to make sure they are in good condition and can be easily accessed by firefighters. Any damaged or obstructed connections should be repaired or replaced.

Standpipe signs and labels: Proper signage is essential for firefighters to quickly locate and use the standpipe system. All standpipe components, including outlets, valves, and fire department connections, should be clearly labeled and easily identifiable. Signs and labels should be inspected regularly to ensure they are visible and legible.

Regular inspections of these standpipe system components and inspection points are essential to ensure the system is functioning properly and will provide an effective water supply to firefighters in the event of a fire. By maintaining and inspecting these components, building owners can help ensure the safety of both occupants and responders.