Welding is a vital part of many industries, allowing the joining of metal structures and components. However, it also presents various hazards that can cause serious injuries or even fatalities if proper safety measures are not implemented. One of the most common and dangerous welding processes is oxy acetylene welding, which involves the use of a highly flammable gas mixture. In order to ensure safe practices, it is essential for welders to undergo an oxy acetylene safety test.

The oxy acetylene safety test is designed to assess a welder’s knowledge and understanding of the potential risks associated with oxy acetylene welding, as well as their ability to implement appropriate safety measures. The test covers a wide range of topics, including the properties and characteristics of acetylene gas, the safe handling and storage of cylinders, the use of appropriate Personal Protective Equipment (PPE), and the proper setup and operation of oxy acetylene welding equipment.

By successfully passing the oxy acetylene safety test, welders demonstrate their competency in identifying potential hazards and taking the necessary precautions to mitigate risks. They learn how to properly handle and store acetylene cylinders, which are highly pressurized and need to be stored in designated areas away from sources of ignition. They also understand the importance of using PPE, such as safety glasses, welding helmets, gloves, and fire-resistant clothing, to protect themselves from heat, sparks, and radiation.

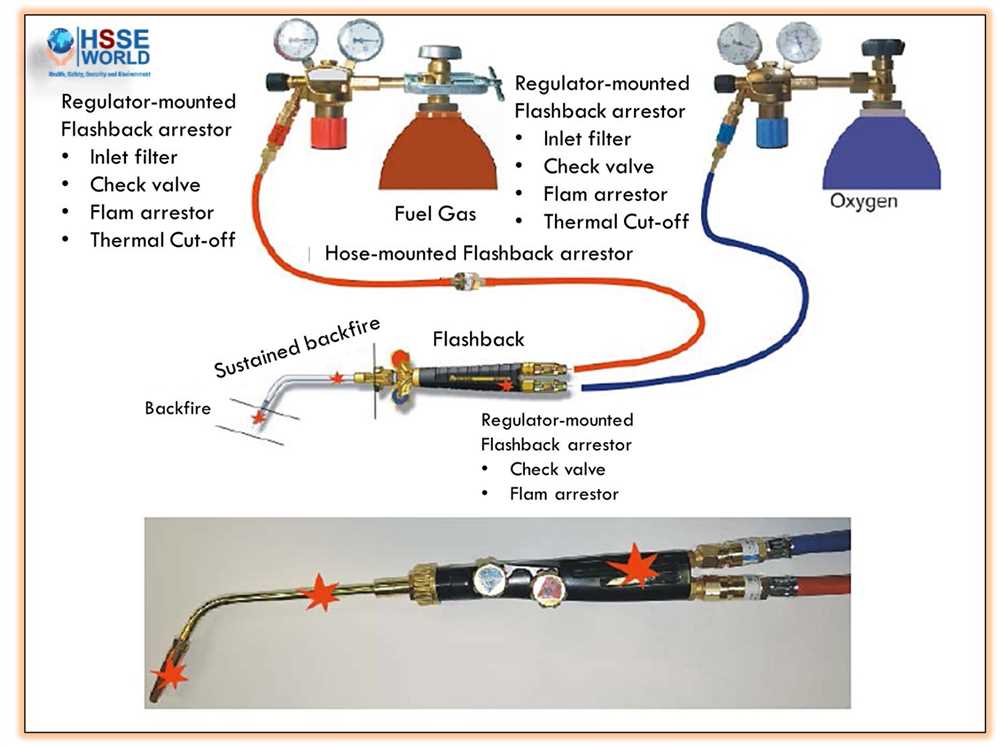

In addition, the oxy acetylene safety test ensures that welders are knowledgeable about the correct setup and operation of oxy acetylene welding equipment. This includes checking for leaks in the gas hoses, maintaining proper gas pressures, and utilizing flame arrestors to prevent flashback. By familiarizing themselves with these safety procedures, welders can prevent accidents such as explosions, fires, and burns, which can occur due to the improper use of oxy acetylene welding equipment.

Oxy Acetylene Safety Test

Oxy acetylene safety test is conducted to assess the knowledge and understanding of individuals regarding the safe handling and use of oxy acetylene equipment. This test is crucial for anyone who works with or around oxy acetylene equipment, as it helps ensure that proper safety precautions are followed to prevent accidents and injuries.

The test covers various aspects of oxy acetylene safety, including equipment inspection, proper handling and storage of cylinders, safe lighting and extinguishing of torches, and understanding of the properties and hazards of acetylene gas. It also evaluates the individual’s knowledge of the appropriate personal protective equipment (PPE) to be worn while working with oxy acetylene equipment.

Key phrases: Oxy acetylene safety test, safe handling, equipment inspection, proper handling, storage of cylinders, safe lighting, extinguishing of torches, properties, hazards of acetylene gas, personal protective equipment (PPE).

- During the test, individuals may be asked to identify potential hazards in oxy acetylene work areas, such as flammable materials, inadequate ventilation, or improper storage of cylinders. They may also be required to demonstrate proper use of equipment, including testing connections for leaks and adjusting regulators.

- Understanding the properties and hazards of acetylene gas is essential for safe oxy acetylene operations. Individuals may be assessed on their knowledge of acetylene’s flammability limits, appropriate flame settings, and the importance of maintaining a safe distance between the torch and combustible materials.

- Knowledge of personal protective equipment is another crucial aspect of the oxy acetylene safety test. Individuals may be asked to identify and describe the proper use of PPE, such as safety glasses, gloves, and fire-resistant clothing.

Passing an oxy acetylene safety test demonstrates that an individual has the necessary knowledge and skills to work safely with oxy acetylene equipment. It is important for employers to ensure that their employees are trained and tested regularly to maintain a safe work environment and prevent accidents.

Understanding Oxy Acetylene Welding

Oxy Acetylene Welding is a type of welding process that uses a combination of oxygen and acetylene gases to generate a high-temperature flame. This flame is then used to melt and join metal pieces together. This process is widely used in industrial settings, such as manufacturing and construction, as it provides a strong and durable bond between metals.

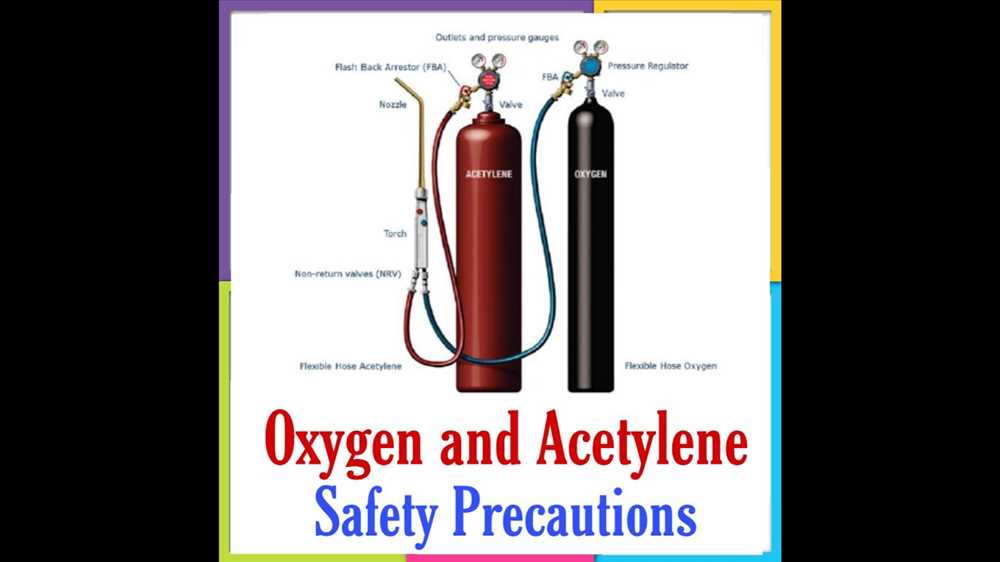

When performing Oxy Acetylene Welding, it is important to understand the various components and their functions. The main components of an Oxy Acetylene Welding setup include the oxygen and acetylene cylinders, pressure regulators, hoses, torch, and welding rod. The oxygen cylinder provides the necessary oxygen gas, while the acetylene cylinder supplies the acetylene gas. The pressure regulators control the flow of gases, ensuring a steady and controlled flame. The hoses connect the cylinders to the torch, allowing for the transfer of gases. The torch, equipped with a nozzle, is responsible for mixing the oxygen and acetylene gases and creating the flame. The welding rod, typically made of a metal alloy, is heated by the flame and used to join the metal pieces together.

Key Safety Considerations

- Before starting any Oxy Acetylene Welding work, it is essential to wear appropriate personal protective equipment (PPE), including goggles, gloves, and fire-resistant clothing. These safety measures help protect against potential hazards such as sparks, heat, and flying debris.

- Proper ventilation is crucial when working with Oxy Acetylene Welding due to the production of hazardous gases, such as carbon monoxide. Working in a well-ventilated area or using exhaust fans can help minimize the risk of inhalation.

- It is important to always inspect the welding equipment before use. Ensure that the hoses are in good condition and free from leaks or damage. Check the pressure regulators and valves for any signs of wear or malfunction. Any faulty equipment should be repaired or replaced before proceeding.

- During welding, it is essential to maintain a safe distance from flammable materials and ensure that there are no combustible substances nearby. Store all flammable materials in designated areas and keep a fire extinguisher within reach.

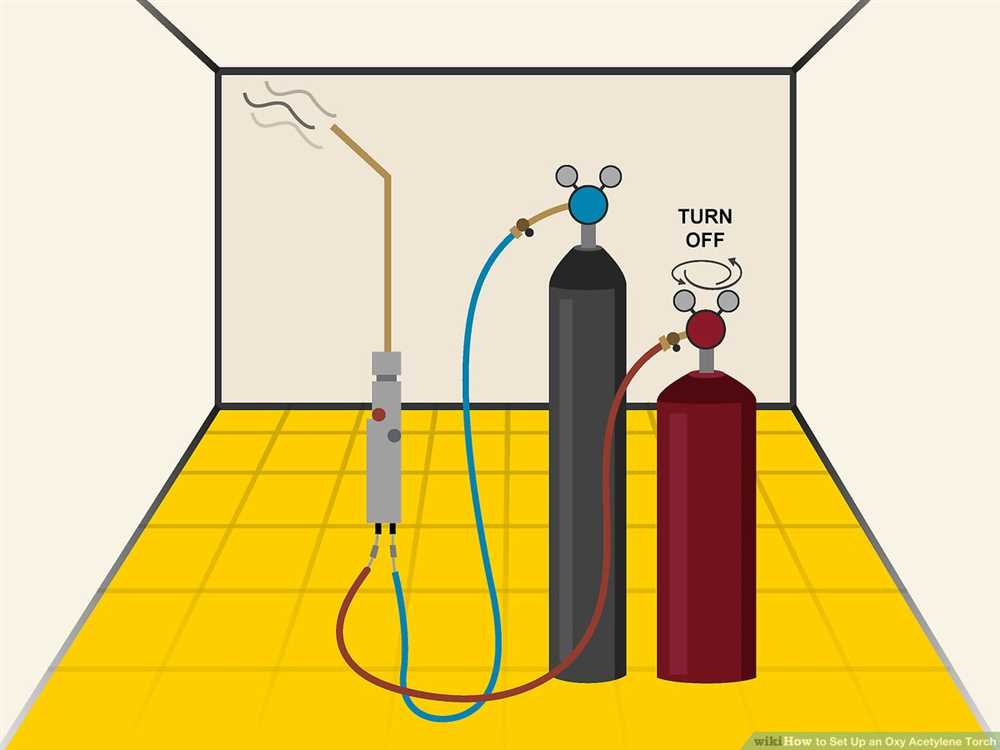

- After completing the welding work, it is necessary to properly shut off the gas supply and release any remaining pressure from the system. This helps prevent accidents and ensures the safe storage of the equipment.

By understanding the fundamentals of Oxy Acetylene Welding and following proper safety procedures, welders can effectively and safely utilize this welding process to join metal pieces and create strong and durable bonds. Regular training and staying updated on safety guidelines are also essential for maintaining a safe working environment.

Safety Measures for Handling Oxy Acetylene Equipment

Handling oxy acetylene equipment requires strict adherence to safety measures to prevent accidents and ensure the well-being of individuals working with this equipment. Here are some important safety measures to follow:

1. Proper Training:

Ensure that all personnel handling oxy acetylene equipment are properly trained and qualified. Training should cover the safe operation of the equipment, understanding of the potential hazards, emergency procedures, and proper handling and storage of cylinders and hoses. Regular refresher training should be conducted to keep employees up to date with the latest safety protocols.

2. Protective Clothing and Equipment:

Always wear appropriate protective clothing and equipment when handling oxy acetylene equipment. This includes flame-resistant clothing, gloves, safety goggles, and a face shield. Protective clothing and equipment should be in good condition and properly fitted to ensure maximum protection.

3. Cylinder Handling:

Handle cylinders with extreme caution and follow proper handling procedures. Store cylinders in a secure, well-ventilated area away from ignition sources, and ensure they are properly secured to prevent falls. Inspect cylinders for damage or leaks before use, and never use a damaged or leaking cylinder.

4. Hose Safety:

Inspect hoses regularly for signs of wear, cracking, or leaks. Use only hoses that are designed for oxy acetylene applications and ensure they are compatible with the equipment being used. Properly secure hoses to prevent tripping hazards, and always keep them away from sharp objects or flames.

5. Fire Safety:

Be prepared for potential fires and know how to respond. Keep a fire extinguisher near the oxy acetylene equipment and know how to use it effectively. Familiarize yourself with the location of emergency exits and ensure they are clear and easily accessible.

By following these safety measures and always practicing caution, individuals can minimize the risks associated with handling oxy acetylene equipment and contribute to a safer working environment.

Section 4: Proper Storage and Handling of Oxy Acetylene Tanks

Proper storage and handling of oxy acetylene tanks is crucial to ensure the safety of workers and prevent accidents. Oxy acetylene tanks should always be stored upright and secured in a well-ventilated area. It is important to keep the tanks away from any sources of ignition, such as open flames, sparks, or electrical equipment.

Storage Area: The storage area for oxy acetylene tanks should be clean, dry, and free from any combustible materials. It should be well-protected from extreme temperatures and direct sunlight. The storage area should also be clearly marked with appropriate signage to indicate the presence of compressed gas cylinders.

Securing the Tanks: Oxy acetylene tanks should be securely fastened to prevent them from falling or tipping over. This can be done using appropriate cylinder restraints or brackets. It is important to make sure that the tanks are not able to move or roll freely, as this can lead to accidents.

Handling: When handling oxy acetylene tanks, it is important to use proper lifting techniques and equipment. Tanks should never be dragged or rolled on the ground, as this can cause damage to the valves or fittings. The tanks should be lifted using a suitable hand truck or cart, and care should be taken to avoid dropping or striking the tanks against any hard surfaces.

- Always ensure that the tank valves are closed tightly when not in use.

- Do not use tools or excessive force to open or close tank valves.

Inspection: Regular inspection of oxy acetylene tanks is essential to identify any signs of damage or leaks. Tanks should be visually inspected for dents, scratches, or corrosion. The valve protection caps should be in place when the tanks are not in use. If any damage or leaks are detected, the tanks should be removed from service and replaced.

| Storage Requirements: | Handling Techniques: | Inspection Checklist: |

|---|---|---|

| Store upright in a well-ventilated area | Use proper lifting equipment | Visually inspect for damage or leaks |

| Away from sources of ignition | Avoid dragging or rolling on the ground | Check valve protection caps |

| Keep area clean and free from combustible materials | Securely fasten to prevent tipping over | Remove from service if damaged or leaking |

Section 5: Precautions while Lighting and Shutting Down the Oxy Acetylene System

Lighting and shutting down the oxy-acetylene system requires careful attention and adherence to safety protocols to prevent accidents or mishaps. The following precautions should be followed:

- Proper Ventilation: Before lighting the oxy-acetylene system, ensure that there is adequate ventilation in the area. This is essential in order to prevent the buildup of acetylene gas, which is highly flammable and can lead to explosions.

- Ignition Source: Make sure that there are no potential ignition sources nearby, such as open flames, sparks, or electrical equipment. These can ignite the acetylene gas and lead to a fire or explosion.

- Secure Gas Cylinders: Ensure that the oxygen and acetylene cylinders are properly secured and upright. They should be stored in a well-ventilated area away from heat, direct sunlight, and flammable substances.

- Purge the Hoses: Before lighting the system, purge the hoses by briefly opening both the oxygen and acetylene valves to allow any accumulated gas or contaminants to escape.

- Check for Leaks: Prior to lighting the oxy-acetylene system, perform a leak check by applying a soapy water solution to all connections. If bubbles appear, tighten the fittings or replace any damaged components.

- Lighting Order: When lighting the oxy-acetylene system, always light the acetylene first and then the oxygen. This ensures a proper mixing ratio and reduces the risk of flashback.

- Proper Shutdown: When shutting down the system, close the acetylene valve first, followed by the oxygen valve. This prevents the flow of acetylene into the oxygen lines and eliminates the risk of an explosion.

- Store Cylinders Safely: After use, store the cylinders in a secure, well-ventilated area away from flammable substances. Ensure that the valves are closed tightly to prevent any leaks.

By following these precautions, the risk of accidents or mishaps while lighting and shutting down the oxy-acetylene system can be significantly reduced. It is essential to always prioritize safety and to be vigilant when working with this system.

Section 6: Fire Safety and Extinguishing Methods

Fires can be a significant hazard when working with oxy-acetylene equipment. It is crucial to have a clear understanding of fire safety and know the proper extinguishing methods to prevent accidents and minimize damages.

During oxy-acetylene operations, the risk of fire arises from the highly flammable nature of acetylene gas and the use of open flames. It is essential to eliminate potential ignition sources, such as sparks, open flames, or hot surfaces, from the work area. Additionally, ensuring proper ventilation is crucial to maintain a safe operating environment and reduce the risk of fire.

Fire Safety Measures:

- Proper Storage: Acetylene cylinders should be stored in well-ventilated areas, away from heat, combustible materials, and potential ignition sources. Adequate signage should be in place to mark the storage area.

- Fire Extinguishers: Fire extinguishers should be readily available in the work area, and all personnel should be trained on their proper use. The types of fire extinguishers suitable for oxy-acetylene fires include carbon dioxide (CO2) extinguishers or dry chemical extinguishers.

- Firewatch: It is advisable to have a firewatcher during operations that involve the use of oxy-acetylene equipment. The firewatcher should remain vigilant, observe the work area for potential fire hazards, and be prepared to take immediate action in case of an emergency.

Extinguishing Methods:

In the event of a fire, it is crucial to act quickly and effectively to extinguish the flames. Here are the recommended extinguishing methods for various types of fires that may occur during oxy-acetylene operations:

| Type of Fire | Extinguishing Method |

|---|---|

| Acetylene Fire | Use a dry chemical extinguisher or carbon dioxide (CO2) extinguisher. Avoid using water, as it can react explosively with acetylene. |

| Oil or Grease Fire | Use a dry chemical extinguisher, carbon dioxide (CO2) extinguisher, or a Class K fire extinguisher specifically designed for kitchen fires. |

| Electrical Fire | Use a carbon dioxide (CO2) extinguisher or a dry chemical extinguisher suitable for electrical fires. Do not use water. |

| General Fire | Use a dry chemical extinguisher or carbon dioxide (CO2) extinguisher. Select the appropriate extinguisher based on the fuel involved in the fire. |

Remember, prompt action and knowledge of the proper extinguishing methods are crucial in effectively combating fires that may occur during oxy-acetylene operations. Regular training and awareness of fire safety measures are vital to maintaining a safe working environment.