Silica is a naturally occurring compound that can be found in various forms in water sources. It is an important parameter to measure in water quality analysis as it can have various impacts on industrial processes and human health. Standard test methods for silica in water are crucial for accurately determining its concentration and ensuring the safety of water sources.

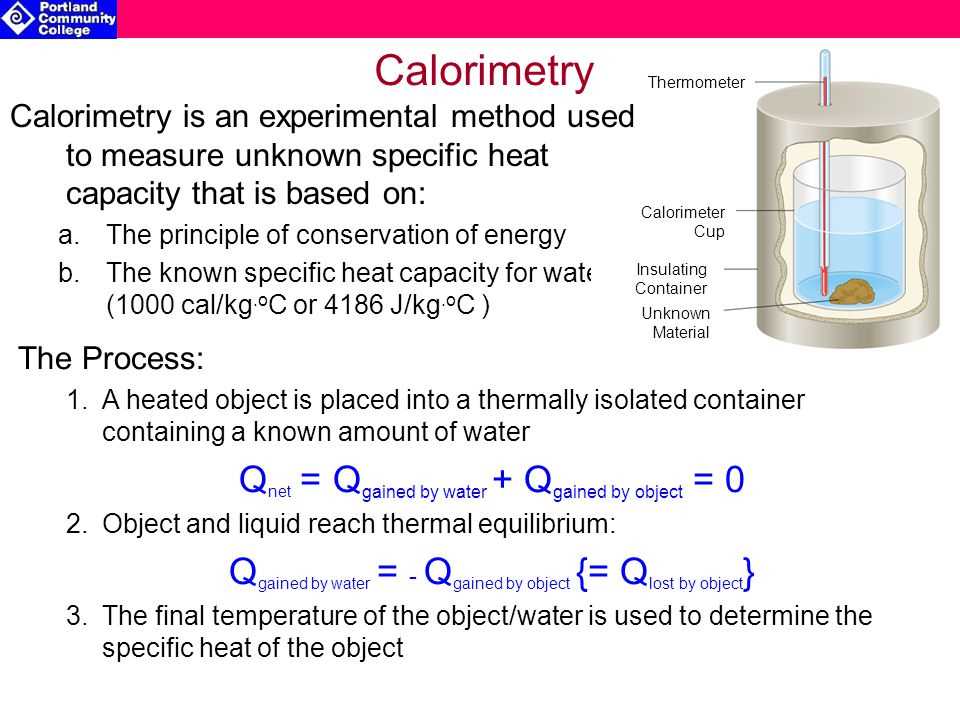

The standard test method for silica in water involves the use of various chemical reagents and instruments to accurately measure the concentration of silica. This method provides a reliable and reproducible way to quantify silica in water samples. The test method typically involves the reaction of silica with an acidic reagent, followed by the measurement of the resulting color change or absorbance using a spectrophotometer.

Having a standardized test method for silica in water is essential for comparing results obtained from different laboratories and ensuring consistent measurements. This allows for better understanding of the levels of silica in various water sources and enables effective monitoring and management strategies. The test method is provided in a pdf format, which makes it easily accessible and widely used by researchers, water treatment professionals, and regulatory agencies.

Standard Test Method for Silica in Water PDF: Overview and Importance

Silica, also known as silicon dioxide, is a naturally occurring compound commonly found in water sources. It is an important parameter to measure and monitor in water quality analysis, as it can have various effects on human health and industrial processes. The standard test method for silica in water provides a systematic approach for its quantification, ensuring accurate and reliable results.

The standard test method for silica in water is outlined in a PDF document that details the specific procedures, equipment, and reagents required for analysis. This method involves the reaction of silica with a reagent to form a colored complex, which can then be measured using a spectrophotometer. The PDF provides step-by-step instructions for sample preparation, reagent addition, and measurement techniques, ensuring consistency and comparability of results.

The importance of measuring silica in water:

- Human health: High levels of silica in drinking water can have adverse effects on human health. Silicosis, a lung disease caused by inhalation of crystalline silica particles, is a well-known example. By monitoring silica levels, authorities can take appropriate actions to ensure safe drinking water for the population.

- Industrial processes: Silica can cause scaling and fouling in industrial equipment, leading to decreased efficiency and increased maintenance costs. By monitoring silica levels in industrial water sources, companies can implement preventive measures to minimize these issues and optimize their processes.

- Environmental impact: Silica can also have an impact on aquatic ecosystems. High levels of silica can promote the growth of certain algae species, leading to imbalances in the ecosystem and potential harm to aquatic life. Monitoring silica in water bodies helps assess and mitigate these environmental impacts.

In conclusion, the standard test method for silica in water outlined in the PDF document provides a comprehensive and reliable approach to quantify silica levels. This analysis is crucial for ensuring safe drinking water, optimizing industrial processes, and safeguarding the environment. By following the standardized procedures and guidelines, accurate measurements can be obtained, enabling effective management of silica levels in water sources.

Significance of Testing Silica in Water

Silica is a naturally occurring compound that can be found in various forms in water sources. It is an essential parameter to monitor in water quality testing, as it can have significant impacts on various industrial processes, environmental conditions, and human health.

One of the main reasons for testing silica levels in water is to assess its potential for scaling or fouling in industrial equipment. Silica can react with other minerals and form silica scale or silicates, which can build up on the surfaces of pipes, boilers, and other equipment. This can result in decreased efficiency, increased energy consumption, and ultimately lead to equipment failure. By testing the silica content in water, industries can implement appropriate treatment methods to prevent scaling and ensure smooth operation of their equipment.

Furthermore, silica in water can also affect the environment and aquatic ecosystems. High levels of silica can promote the growth of certain types of algae, leading to algal blooms. These blooms can negatively impact water quality, reduce oxygen levels, and harm aquatic life. Testing silica in water bodies helps in monitoring and managing these risks, enabling authorities to take necessary actions to preserve the health of the ecosystem.

Lastly, silica in drinking water can have potential health implications. High levels of silica have been associated with the development of kidney stones, lung diseases, and other health issues. Regular testing of silica in drinking water sources helps ensure that the concentration is within acceptable limits defined by regulatory bodies, protecting public health.

In conclusion, testing silica in water is of utmost importance due to its impact on industrial processes, environmental conditions, and human health. By monitoring silica levels, industries can prevent equipment failure and maintain efficiency, authorities can preserve the health of aquatic ecosystems, and public health can be safeguarded from potential health risks.

Understanding Silica Levels in Water

Silica is a naturally occurring compound found in water sources and is a common constituent of many minerals, rocks, and soils. Silica can be present in water in various forms, including dissolved, colloidal, and particulate. Monitoring silica levels in water is important for several reasons, as it can have both positive and negative effects on various industrial and environmental processes.

One of the main reasons for measuring silica in water is its impact on the efficiency and lifespan of industrial equipment. Silica can cause scaling and fouling in boilers, cooling towers, and other heating and cooling systems, leading to decreased heat transfer efficiency and increased energy consumption. High silica levels can also result in the formation of deposits on surfaces, reducing the effectiveness of water treatment processes and impacting the quality of the treated water.

The standard test method for silica in water is a widely accepted procedure that provides accurate and reliable measurements of silica concentration. This method involves the colorimetric determination of silica using a reagent that reacts with silica to form a colored complex, which can then be measured using a spectrophotometer. The test method has been standardized to ensure consistency and comparability of results across different laboratories.

Knowing the silica levels in water is not only important for industrial processes but also for environmental purposes. High levels of silica can be indicative of geological activity and can affect the overall ecosystem. Silica is an essential nutrient for certain organisms, such as diatoms and sponges, which play a crucial role in aquatic ecosystems. However, excessive silica levels can disrupt the balance of aquatic ecosystems, leading to algal blooms and other ecological disturbances.

In conclusion, understanding silica levels in water is crucial for maintaining the efficiency of industrial processes and preserving the health of aquatic ecosystems. Regular monitoring and accurate measurement of silica concentrations using standardized test methods are essential for effective water management and ensuring the sustainability of water resources.

The Importance of Test Method Standardization

Test method standardization plays a crucial role in ensuring accurate and reliable measurement of silica levels in water. Standardized test methods provide a consistent framework for testing, allowing for comparability of results across different laboratories, equipment, and operators. This is particularly important in the field of water analysis, where precise measurements are essential for evaluating water quality and ensuring compliance with regulatory standards.

Having a standardized test method for silica in water is essential for several reasons. Firstly, it helps to minimize variability and bias in the measurement process. By providing clear instructions on sample collection, preparation, analysis, and reporting, standardized methods reduce the potential for errors and inconsistencies that can arise from using different approaches or techniques.

Standardized test methods also facilitate quality control and quality assurance practices. They establish a benchmark against which the accuracy and reliability of measurements can be evaluated. By following a standardized method, laboratories can ensure that their results are traceable and compatible with other laboratories using the same method. This promotes confidence in the data and allows for meaningful comparison and communication of results.

- Consistency: Standardization ensures consistent measurement practices, leading to reliable and comparable results.

- Accuracy: Standardized methods help to minimize errors and biases, enhancing the accuracy of measurements.

- Interoperability: Using the same test method allows for the exchange and comparison of data between different laboratories and research studies.

- Risk assessment: Standardized methods facilitate the evaluation of silica levels in water, helping to identify potential risks and take appropriate measures for mitigation.

In conclusion, test method standardization is of paramount importance for accurate and reliable measurement of silica levels in water. It ensures consistency, accuracy, and interoperability, while facilitating quality control and risk assessment. By adhering to standardized methods, laboratories can generate trustworthy data that is essential for making informed decisions regarding water quality management and protection.

Basics of the Standard Test Method for Silica in Water

The Standard Test Method for Silica in Water is a widely used method for determining the concentration of silica in water samples. Silica, also known as silicon dioxide (SiO2), is a compound that can be found in natural water sources such as lakes, rivers, and groundwater. Monitoring silica levels in water is important as it can indicate the potential for scaling in industrial processes, as well as the quality of the water for drinking or other purposes.

The test method for silica in water involves several steps. First, a water sample is collected and filtered to remove any particulate matter that could interfere with the analysis. The filtered sample is then acidified to convert any silica present into a soluble form. Next, a color reagent is added to the sample, which reacts with the silica to form a colored compound. The intensity of the color is proportional to the concentration of silica in the sample. The absorbance of the colored solution is then measured using a spectrophotometer.

To ensure accurate results, it is important to follow the standard test method for silica in water carefully. This includes using appropriate equipment, maintaining proper sample handling techniques, and calibrating the spectrophotometer using a silica standard solution. The test method provides specific instructions for preparing the color reagent and determining the absorbance of the colored solution.

The standard test method for silica in water is widely recognized and accepted in various industries, including water treatment, environmental monitoring, and industrial processes. It has been validated through inter-laboratory studies and is used by regulatory agencies to enforce water quality standards. The method provides a reliable and efficient way to measure silica levels in water, allowing for informed decision-making and appropriate treatment if necessary.

Steps and Procedures for Conducting the Test

Performing the silica test in water involves several important steps and procedures to ensure accurate and reliable results. It is vital to follow these instructions closely to obtain precise measurements of silica concentration in the water sample. The following outlines the general steps and procedures for conducting the test:

1. Sample Collection: Collect a representative water sample from the source of interest using a clean and uncontaminated container. It is crucial to ensure that the sampling container does not contribute any silica to the sample.

2. Sample Preservation: If necessary, preserve the water sample to prevent any changes in silica concentration over time. Preservation methods may include acidification or refrigeration, depending on the specific requirements of the test method being used.

3. Calibration: Before starting the test, calibrate the analytical instrument or test kit according to the manufacturer’s instructions. This step ensures accurate measurements by establishing a baseline for comparison.

4. Reagent Preparation: Prepare the necessary reagents and standards required for the silica test. Follow the instructions provided in the test method to ensure proper reagent mixing and standard preparation.

5. Test Procedure: Perform the test according to the specified method. This may involve adding the reagents to the water sample, allowing for a reaction time, and measuring the resulting color change or analyte concentration using the appropriate equipment.

6. Data Analysis: Record the obtained measurement or color change and compare it to the calibration curve or standard values. Use the appropriate formula or software to calculate the silica concentration in the water sample.

7. Quality Control: As part of the quality control procedure, perform regular checks using control samples of known concentration. These checks help ensure the accuracy and consistency of the test results.

- 8. Reporting: Document the test results, including the silica concentration, test method used, and any relevant observations or notes. Adhere to any reporting guidelines or regulations specific to the industry or jurisdiction.

- 9. Troubleshooting: In case of any unexpected results or issues during the test, troubleshoot the problem by reviewing the test procedure, instrumentation, and reagents used. Consult the test method’s guidelines or an expert if necessary.