When it comes to testing the load capacity of structures such as bridges and foundations, traditional methods have their limitations. They often require extensive setup time, can be expensive, and may not provide accurate results. This is where the statnamic load test comes into play – a revolutionary approach that offers a more efficient and effective solution.

Unlike traditional load tests, the statnamic load test utilizes a large hydraulic device to apply dynamic loads to the structure being tested. This dynamic loading mimics the real-world conditions that the structure will face during its lifespan, providing a more accurate representation of its load capacity.

One of the key advantages of the statnamic load test is its efficiency. Traditional load tests can take days or even weeks to set up and execute, whereas the statnamic test can be conducted in a matter of hours. This not only saves time but also reduces the disruption caused during construction or renovation projects.

In addition to its efficiency, the statnamic load test offers increased safety compared to traditional methods. By applying dynamic loads instead of static loads, engineers can better assess the behavior and ultimate capacity of the structure. This helps identify potential weaknesses and allows for informed decision-making regarding the design and construction of the project.

The statnamic load test has quickly gained popularity in various industries, including civil engineering and construction. Its ability to provide accurate and timely results, combined with its cost-effectiveness and safety benefits, make it a preferred choice for load capacity testing. As technology continues to advance, the statnamic load test promises to revolutionize the way we test and evaluate structures for load capacity, ultimately leading to safer and more efficient construction practices.

What is a Statnamic Load Test?

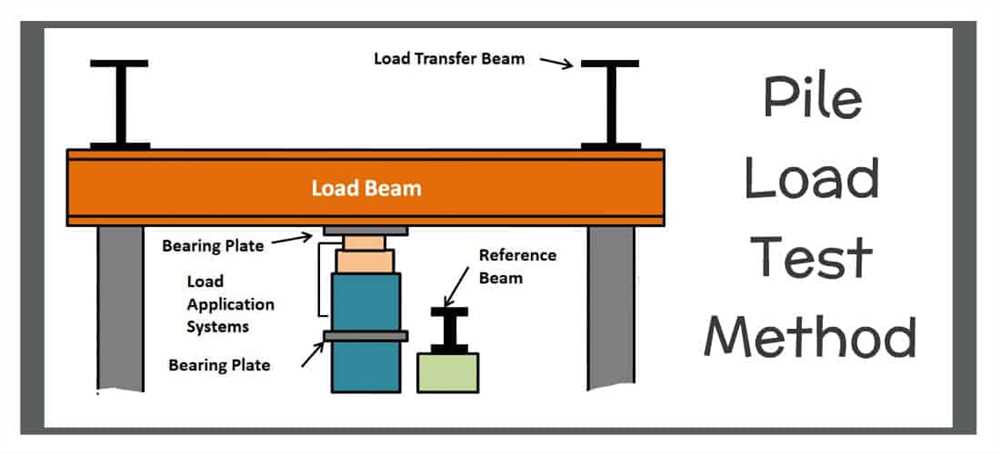

The Statnamic load test is a dynamic load testing method used to determine the ultimate bearing capacity and settlement behavior of deep foundation elements, such as piles or drilled shafts. It involves applying an impact load to the top of the foundation element using a drop weight, which generates a force that is transmitted through a series of reaction beams and cables. The resulting load and displacement measurements are used to assess the load-bearing capacity and integrity of the foundation element.

Unlike traditional static load tests, which apply a static load to the foundation element and measure its response over a period of time, the Statnamic load test applies a dynamic load in a short duration. This allows for a quick assessment of the foundation element’s performance and reduces the testing time compared to static load tests. Additionally, the dynamic nature of the test simulates the dynamic forces that a foundation element may experience during its intended use, providing a more realistic assessment of its behavior.

During a Statnamic load test, the drop weight is raised to a predetermined height and then released to free fall onto a reaction surface. The resulting impact creates a dynamic load that is transmitted through the reaction beams and cables to the foundation element. Load cells and displacement sensors placed on the foundation element and reaction system measure the resulting forces and movements, allowing for the calculation of the ultimate bearing capacity and settlement behavior of the foundation element.

The data collected during a Statnamic load test can be used to verify design assumptions, validate load capacity predictions, and assess the performance of foundation elements. This information is valuable for engineers and contractors involved in deep foundation projects, as it helps ensure the integrity and safety of the constructed structures.

Understanding the concept of Statnamic Load Testing

Statnamic load testing is a technique used to determine the load capacity and behavior of deep foundations, such as piles, driven or drilled shafts. It involves applying a dynamic load to the foundation and measuring its response, allowing engineers to assess its performance and ensure its safety and stability. This method offers several advantages over traditional static load testing, including the ability to simulate real-world dynamic conditions and the ability to test multiple foundations in a shorter period of time.

During a Statnamic load test, a specially designed test apparatus called a statnamic device is used to apply a dynamic load to the foundation. The device consists of a steel reaction frame that is connected to the foundation through a steel rod or cable. By applying an impact force to the reaction frame, the statnamic device generates a dynamic load that simulates the actual behavior of the foundation under dynamic conditions.

This dynamic load is measured by sensors attached to the foundation and the statnamic device, allowing engineers to collect data on parameters such as load magnitude, load duration, and load distribution. This data is then analyzed to determine the foundation’s load capacity, deformation characteristics, and overall performance. The results of the test can be used to optimize foundation design, verify design assumptions, and ensure compliance with safety standards and regulations.

Overall, Statnamic load testing provides a reliable and efficient method for evaluating the performance of deep foundations. By simulating dynamic conditions and collecting accurate data, engineers can make informed decisions regarding foundation design, construction, and load capacity, ultimately ensuring the safety and reliability of the built infrastructure.

The importance of Statnamic Load Testing in construction and engineering

Statnamic Load Testing is a critical component in the construction and engineering industries. This innovative testing method allows engineers to accurately assess the load-bearing capacity of foundations and structures, ensuring their safety and reliability.

One of the key advantages of Statnamic Load Testing is its ability to simulate real-world load conditions. By replicating the dynamic loads that structures are likely to encounter during their lifespan, engineers can obtain valuable insights into the structural behavior under various scenarios. This is particularly important in earthquake-prone regions, where buildings must withstand intense seismic forces.

Statnamic Load Testing offers several benefits for construction projects:

- Improved safety: By subjecting foundations and structures to realistic load conditions, engineers can identify potential deficiencies or weaknesses. This allows them to make necessary design modifications or take remedial actions to ensure the safety of the structure and its occupants.

- Optimized designs: The data obtained from Statnamic Load Testing enables engineers to fine-tune their designs and specify the appropriate materials and dimensions for foundations and structural elements. This leads to optimized designs that maximize efficiency and minimize construction costs.

- Validation of design assumptions: During the design phase, engineers make assumptions about the behavior of structures under load. Statnamic Load Testing allows them to validate these assumptions and make any necessary adjustments based on real-world testing data.

- Quality control: Statnamic Load Testing serves as a quality control measure, ensuring that construction projects meet the required standards and specifications. It helps identify any deviations from the intended design and allows for prompt corrective actions.

Overall, Statnamic Load Testing plays a crucial role in the construction and engineering industries by providing valuable data on the load-bearing capacity and behavior of structures. It allows engineers to make informed decisions, improve safety, optimize designs, validate assumptions, and ensure quality control throughout the construction process.

The Process of Conducting a Statnamic Load Test

A Statnamic load test is a type of dynamic load test used to assess the behavior and structural integrity of deep foundations such as piles or drilled shafts. This test involves applying a dynamic load to the foundation using a high-speed hydraulic system, known as a Statnamic load cell.

The process of conducting a Statnamic load test typically involves the following steps:

- Preparation: Before the test, the test site is prepared by cleaning the foundation and removing any obstructions. The Statnamic load cell is then positioned on top of the foundation.

- Instrumentation: Various sensors and instruments are installed at different locations on the foundation to measure the strain, displacement, and other related parameters during the test. These instruments are securely attached using clamps or adhesive.

- Load Application: The Statnamic load cell is activated, and a dynamic load is applied to the foundation. The load is typically applied in multiple cycles, with each cycle lasting for a specific duration and magnitude. The load is increased gradually in each cycle to simulate the expected load conditions that the foundation will experience in its intended use.

- Data Acquisition: During the load test, data from the installed instruments is continuously recorded using data acquisition systems. This data includes measurements of strain, displacement, acceleration, and other relevant parameters. These measurements are used to analyze the behavior of the foundation under the applied load.

- Data Analysis: After the load test, the recorded data is analyzed to assess the performance of the foundation. Various analysis techniques, such as curve fitting, numerical modeling, and statistical methods, may be used to interpret the data and determine the capacity, stiffness, and other important characteristics of the foundation.

- Reporting: Finally, a comprehensive test report is prepared, summarizing the test procedure, observed behavior of the foundation, and the calculated parameters. This report is typically submitted to the project stakeholders, including the design engineers and regulatory authorities, to evaluate the foundation’s suitability for its intended use.

In conclusion, conducting a Statnamic load test involves thorough preparation, careful instrumentation, precise load application, accurate data acquisition, sophisticated data analysis, and comprehensive reporting. This testing process provides valuable insights into the behavior and performance of deep foundations, helping engineers make informed decisions regarding their design and construction.

Preparation and setup for a Statnamic Load Test

Before conducting a Statnamic load test, proper preparation and setup are essential to ensure accurate and reliable results. This involves several key steps and considerations to be taken into account.

1. Site selection: The first step in preparing for a Statnamic load test is to carefully select the site where the test will be conducted. The site should have suitable soil conditions and sufficient space to accommodate the test equipment. It is important to consider factors such as accessibility, potential obstructions, and the proximity to neighboring structures.

2. Equipment mobilization: Once the site is selected, the necessary equipment for the Statnamic load test needs to be mobilized. This includes the Statnamic device itself, as well as any auxiliary equipment such as reaction piles or anchorages. The equipment should be inspected to ensure it is in proper working condition and meets all safety requirements.

3. Test setup: The next step is to set up the test apparatus at the selected site. This involves installing the Statnamic device or reaction piles, as well as any necessary instrumentation such as strain gauges or displacement sensors. The setup should be designed to accurately measure the applied load and the response of the tested structure.

4. Calibration: Before conducting the load test, it is important to calibrate the equipment to ensure accurate measurements. This involves applying known loads to the system and comparing the measured responses to the expected values. Any necessary adjustments or calibrations should be made before proceeding with the test.

5. Safety measures: Throughout the preparation and setup process, it is crucial to prioritize safety. This includes taking precautions to protect workers and the surrounding environment from potential hazards. Safety protocols should be established, and all personnel involved in the test should be trained on proper procedures and emergency protocols.

In conclusion, successful Statnamic load testing requires thorough preparation and setup. By carefully selecting the site, mobilizing the equipment, setting up the test apparatus, calibrating the equipment, and prioritizing safety measures, accurate and reliable results can be obtained.

Monitoring and Recording Data during a Statnamic Load Test

In a Statnamic load test, it is crucial to monitor and record data accurately to evaluate the performance and behavior of the tested structure. This allows engineers to gather valuable insights and make informed decisions regarding the structural integrity and load-carrying capacity of the tested object. The monitoring process involves several stages, including pre-test setup, test execution, and post-test analysis.

Pre-Test Setup: Prior to conducting a Statnamic load test, sensors and instruments are strategically placed on the structure to capture key performance indicators. These instruments may include accelerometers, strain gauges, displacement transducers, and load cells. The sensors are carefully calibrated to ensure accurate data collection during the test. Additionally, a data acquisition system is set up to record and store the collected data for further analysis.

Test Execution: During the Statnamic load test, the structure is subjected to dynamic loading using a drop or impact hammer. As the load is applied, the sensors capture data related to acceleration, strain, displacement, and force. The data acquisition system records this information in real-time, providing a comprehensive dataset for analysis. It is important to ensure that the monitoring equipment and sensors are functioning properly throughout the test to avoid any data loss or inaccuracies.

Post-Test Analysis: After the Statnamic load test is completed, the recorded data is analyzed to determine the behavior of the structure under dynamic loading. Engineers use various techniques and software to process the data and extract relevant parameters such as the ultimate capacity, load-displacement curve, and natural frequency response. The collected data is compared with design specifications and industry standards to assess the safety and performance of the tested structure. Any deviations or abnormalities in the data are thoroughly examined to identify potential issues or areas of improvement.

In conclusion, monitoring and recording data during a Statnamic load test is crucial for evaluating the structural performance and integrity. Accurate data collection and analysis provide engineers with valuable insights into the load-carrying capacity and behavior of the tested structure, allowing for informed decisions and ensuring the safety and reliability of the project.