Table saws are essential tools for cutting wood and other materials, but they can also be extremely dangerous if not used properly. In order to ensure the safety of users, table saw manufacturers have developed various safety features and technologies. However, it is important for users to understand and test these safety features before using the table saw.

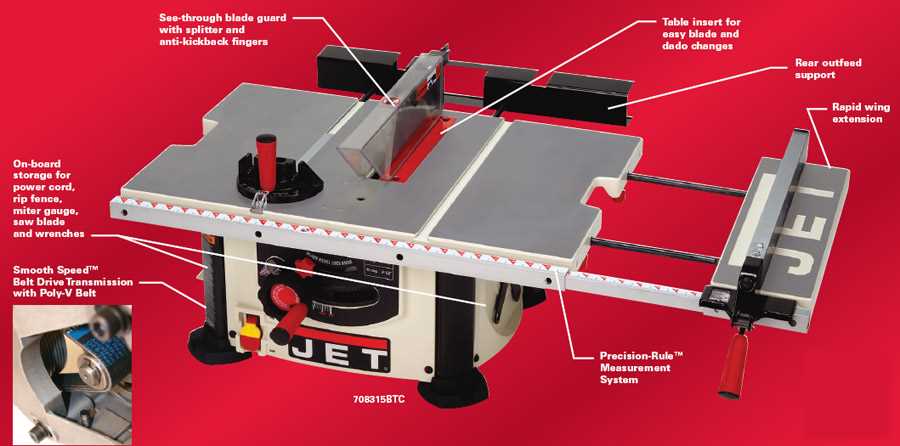

One of the most important safety features of a table saw is the blade guard. This is a protective cover that encloses the blade, preventing accidental contact with the spinning blade. To test the blade guard, users should make sure it is properly adjusted and securely in place before turning on the saw. They should also check that the guard moves freely and does not obstruct the cutting process.

Another crucial safety feature is the anti-kickback device. This device helps prevent the wood from being thrown back at the user in the event of a kickback. Users can test the effectiveness of the anti-kickback device by feeding a piece of wood into the saw at a moderate speed. The device should engage and prevent the wood from being thrown back.

Users should also test the safety mechanisms for the table saw’s power switch. It is important to ensure that the switch is easily accessible and can be quickly turned off in case of an emergency. Users should also verify that the switch automatically turns off the saw in the event of a power outage or power surge.

Table Saw Safety Test: What You Need to Know

When working with a table saw, it is important to prioritize safety to prevent accidents and injuries. One way to ensure that you are using the table saw safely is by conducting a table saw safety test. This test helps you assess your knowledge and understanding of the necessary precautions and procedures to follow when operating a table saw.

The table saw safety test covers various aspects of using a table saw, including proper setup, maintenance, and operation. You will be evaluated on your ability to correctly identify and use the safety features of the table saw, such as the blade guard, anti-kickback pawls, and riving knife. Additionally, you will be assessed on your knowledge of safety protocols, such as wearing appropriate protective gear and maintaining a clean and organized work area.

To pass the table saw safety test, it is essential to familiarize yourself with the manufacturer’s instructions and guidelines for your specific table saw model. You should also understand how to properly adjust the blade height and angle, and how to safely feed the material through the saw. It is crucial to maintain a stable stance and secure grip on the material to prevent accidents.

The table saw safety test may also include questions on emergency measures, such as what to do in case of kickback or blade binding. Knowing how to respond to these situations can help minimize the risk of injury. It is crucial to understand the importance of unplugging the saw before making any adjustments or performing maintenance tasks.

By successfully completing the table saw safety test, you are demonstrating your commitment to safety and your ability to operate a table saw responsibly. Remember to always prioritize safety when working with power tools, and continuously update your knowledge and skills to ensure a safe working environment.

Understanding the Dangers of Table Saws

Table saws are powerful and versatile tools commonly used in woodworking and construction projects. While they are essential for many tasks, it is crucial to understand the potential dangers associated with their use. Failure to follow proper safety precautions and procedures can result in severe injuries, including amputations, lacerations, and other life-threatening accidents.

One of the most significant dangers of table saws is the risk of blade contact. The sharp and rotating blade can cause serious injuries if it comes into contact with fingers, hands, or other body parts. It is essential to always keep hands and fingers at a safe distance from the blade, and never attempt to guide or control the workpiece by hand. The use of push sticks, featherboards, and other safety devices is crucial to maintaining a safe working distance from the blade.

Table saw kickback is another significant hazard that all users should be aware of. Kickback occurs when the workpiece binds or gets caught by the rear of the blade and is thrown back towards the operator. This sudden and forceful movement can cause severe injuries. To prevent kickback, it is vital to use appropriate feeding techniques, such as using a push stick or evenly distributing pressure across the workpiece. Additionally, using a riving knife or splitter can help prevent kickback by keeping the wood from pinching the blade.

Dust and debris control is also an essential aspect of table saw safety. The accumulation of sawdust and debris around the blade and work area can not only hinder visibility but also increase the risk of accidents. Regularly cleaning the saw and work area, using dust collection systems, and wearing appropriate personal protective equipment, such as goggles and masks, can greatly reduce the risk of accidents caused by dust and debris.

Finally, it is crucial to ensure that the table saw is properly maintained and in good working condition. Regularly checking for any loose or damaged parts, keeping the blade sharp, and using the appropriate blade for the task at hand are essential for safe operation. Additionally, operators should familiarize themselves with the specific safety features and controls of their table saw and always follow the manufacturer’s instructions.

By understanding and being aware of the potential dangers associated with table saws, users can take the necessary precautions to protect themselves and others in the workspace. Following proper safety procedures and using appropriate safety devices can help prevent accidents and ensure safe and efficient operation of table saws.

Importance of Proper Safety Equipment

When it comes to operating a table saw, proper safety equipment is essential to ensure the well-being of the user. The use of safety equipment not only mitigates the risk of serious injuries, but also enhances the overall productivity and efficiency of the work.

One key piece of safety equipment for working with a table saw is a pair of safety goggles or glasses. These protect the eyes from flying debris, wood chips, and other particles that can cause significant eye injuries. It is important to wear safety goggles with side shields to provide full coverage and protection.

Protective gloves

Another crucial safety accessory is a pair of protective gloves made of durable material. These gloves not only protect the hands and fingers from cuts and scrapes, but also provide a better grip on the materials being worked on. This reduces the risk of accidents and allows the user to have better control over the saw and the piece of wood being cut.

Ear protection

The table saw can generate high levels of noise, which can be damaging to the ears if exposed for extended periods of time. Therefore, it is important to wear ear protection such as earplugs or earmuffs to prevent hearing damage. By using ear protection, workers can concentrate better, communicate effectively, and avoid potential long-term hearing loss.

Dust masks

Working with a table saw generates a significant amount of dust and debris, which can be harmful if inhaled. Dust masks or respirators should be worn to protect the respiratory system from fine particles and sawdust. These masks help to ensure better air quality and reduce the risk of respiratory problems.

Conclusion

Overall, the use of proper safety equipment is crucial when using a table saw. Safety goggles, protective gloves, ear protection, and dust masks are just a few examples of the essential safety accessories that should be utilized to prevent injuries and promote a safe working environment. By investing in the right safety equipment and practicing good safety habits, individuals can confidently and efficiently carry out their work while minimizing the risk of accidents and injuries.

Preparing the Work Area for Table Saw Use

Setting up the work area for safe table saw use

Before using a table saw, it is important to properly set up the work area to ensure safety. This involves clearing the space around the saw, organizing materials and tools, and creating a comfortable and efficient working environment.

Clearing the area: Before starting any work on the table saw, it is essential to clear the area of any clutter or debris. Make sure there are no obstacles or tripping hazards near the saw. This includes removing any unnecessary tools, materials, or equipment from the work surface and surrounding areas.

Organizing materials and tools: To maximize efficiency and safety, it is important to properly organize materials and tools before using the table saw. Keep all cutting materials, such as wood or metal, neatly stacked or stored in a designated area. Ensure that all necessary tools, such as push sticks, measuring tools, and safety equipment, are easily accessible and within reach.

Creating a comfortable working environment: Working in a comfortable and well-lit environment is crucial for safe table saw use. Adjust the lighting in the work area to minimize shadows and improve visibility. Set the table saw at a comfortable height that allows for proper posture and body mechanics. Consider using anti-fatigue mats or cushioned flooring to reduce strain on the feet and legs during prolonged use of the table saw.

By properly preparing the work area for table saw use, you can minimize the risk of accidents and create a safer and more efficient working environment.

Clearing the Area of Debris

When operating a table saw, it’s crucial to ensure that the area around the saw is clear of any debris or obstacles. Even the smallest piece of wood or other material can pose a significant safety hazard and lead to accidents or injuries. Therefore, it is essential to take the time to thoroughly clean the workspace before starting any cutting tasks.

Before starting:

- Clear the saw table: Remove all unnecessary items from the table saw, such as papers, tools, or any debris that may have accumulated from previous projects. Keeping the saw table clean will provide a clear and unobstructed surface for cutting.

- Check the floor: Inspect the floor around the table saw and remove any sawdust, wood chips, or other loose materials that could cause slipping or tripping hazards. Sweeping or vacuuming the area will help maintain a safe working environment.

- Remove obstructions: Make sure there are no objects, such as cords, hoses, or other equipment, that could interfere with the operation of the table saw or potentially cause accidents. Keep these items well away from the saw and out of the way of your workspace.

By clearing the area of debris and taking the time to create a clean and organized workspace, you can significantly reduce the risk of accidents and injuries while using a table saw. Remember, safety should always be a top priority when operating any power tool, and keeping a clean work area is an important part of maintaining a safe working environment.

Ensuring Adequate Lighting

Proper lighting is essential when using a table saw to ensure safety and accuracy. Insufficient lighting can lead to a variety of hazards, including accidents and incorrect cutting. In order to prevent these issues, it is important to take certain precautions and ensure that the work area is well-lit.

1. Positioning: Place the table saw in an area that receives ample natural light during the day. Position it near a window or under a skylight. This will not only provide adequate lighting but also improve visibility and reduce strain on the eyes.

2. Supplementary Lighting: In addition to natural light, it is important to have supplementary lighting sources in the work area. Install overhead lights or use adjustable work lights that can be directed towards the table saw and the cutting area. These lights should be positioned to minimize shadows and provide uniform lighting across the workspace.

3. Light Color: Pay attention to the color temperature of the lighting used. It is advisable to use lighting with a color temperature around 5000K, which mimics natural daylight. This type of lighting provides better visibility and reduces eye strain compared to warmer or cooler light sources.

4. Light Placement: Ensure that the lights are strategically placed to illuminate the entire table saw and cutting area. Avoid placing lights directly above the blade as this can create shadows and hinder visibility. Position the lights at an angle to minimize glare on the workpiece.

5. Maintenance: Regularly check and maintain the lighting fixtures to ensure they are in proper working condition. Replace any burnt-out bulbs or faulty fixtures immediately to maintain consistent and reliable lighting in the work area.

6. Personal Lighting: Consider using a portable headlamp or a small task light attached to safety glasses to provide additional focused lighting while operating the table saw. This can help improve visibility and accuracy, especially when working on intricate cuts or in dimly lit spaces.

By ensuring adequate lighting in the work area, table saw users can improve safety, reduce the risk of accidents, and achieve more accurate cuts. Prioritizing lighting can significantly enhance the overall experience and productivity when working with a table saw.

Using the Table Saw Correctly and Safely

The table saw is a powerful tool that can be extremely useful in woodworking projects, but it is also one of the most dangerous tools in the workshop. It is important to use the table saw correctly and practice safety precautions to prevent accidents and injuries.

1. Wear the right protective gear: Always wear safety goggles or a face shield to protect your eyes from flying debris. Use hearing protection to prevent hearing damage from the loud noise of the saw. Wear appropriate clothing and sturdy, non-slip footwear to prevent accidents.

2. Check and adjust the saw: Before using the table saw, make sure it is in good working condition. Check the blade guard and splitter to ensure they are properly aligned and functioning correctly. Adjust the blade height and angle according to your project requirements.

3. Use push sticks and featherboards: When cutting small or narrow pieces of wood, use push sticks or featherboards to keep your hands and fingers away from the blade. This will help you maintain control over the workpiece and prevent accidental contact with the spinning blade.

4. Never reach over the blade: Avoid reaching over the blade or getting too close to it while it is running. This can lead to serious injuries if your hand accidentally slips and comes into contact with the blade. Use a push stick or a push block to guide the wood through the saw instead.

5. Keep the work area clean and organized: A cluttered work area can impede your movement and increase the risk of accidents. Keep the saw table clear of tools, scraps, and other debris. Make sure the floor around the saw is clear of trip hazards.

6. Always use the blade guard and riving knife: The blade guard and riving knife are essential safety features of the table saw. They help prevent kickback and protect your hands from accidental contact with the blade. Never remove or disable these safety devices.

- Always be mindful of your body position and keep your hands a safe distance from the blade.

- Never rush the cutting process; take your time to ensure accuracy and safety.

- Keep children and pets away from the table saw at all times.