Testex tape is a widely used tool in the field of surface preparation and corrosion assessment. It is designed to measure the surface profile of a substrate, which is an essential factor in ensuring proper adhesion of coatings and preventing premature failure.

The Testex tape standard, often referred to as the Testex replica tape, is a reliable method for evaluating the roughness of a surface. It consists of a foam-backed adhesive tape with a series of coating thicknesses, which are transferred onto the surface being tested. These transferred replicas are then measured using a precision spring-loaded micrometer to determine the peak-to-valley profile.

The Testex tape standard provides a non-destructive and cost-effective way to assess the roughness of a surface. It is commonly used in industries such as marine, oil and gas, automotive, and aerospace, where the quality of surface preparation is critical for the performance and longevity of coatings. By using the Testex tape standard, professionals can ensure that the surface is properly prepared and that the coating will adhere properly, reducing the risk of corrosion and other coating failures.

What is Testex Tape Standard?

Testex Tape Standard is a commonly used tool for measuring the surface profile of a substrate. It is a self-adhesive tape with a compressible foam layer on top. The tape is pressed against the surface, and when removed, it leaves an imprint of the surface profile on the foam. This imprint can then be measured using a separate instrument called a depth micrometer.

The purpose of using Testex Tape Standard is to ensure that the surface profile of a substrate meets a certain standard. This is important in industries where the quality and performance of painted or coated surfaces are critical, such as automotive, aerospace, and marine industries. By measuring the surface profile, manufacturers can ensure that the coating will adhere properly and provide adequate protection against corrosion or other environmental factors.

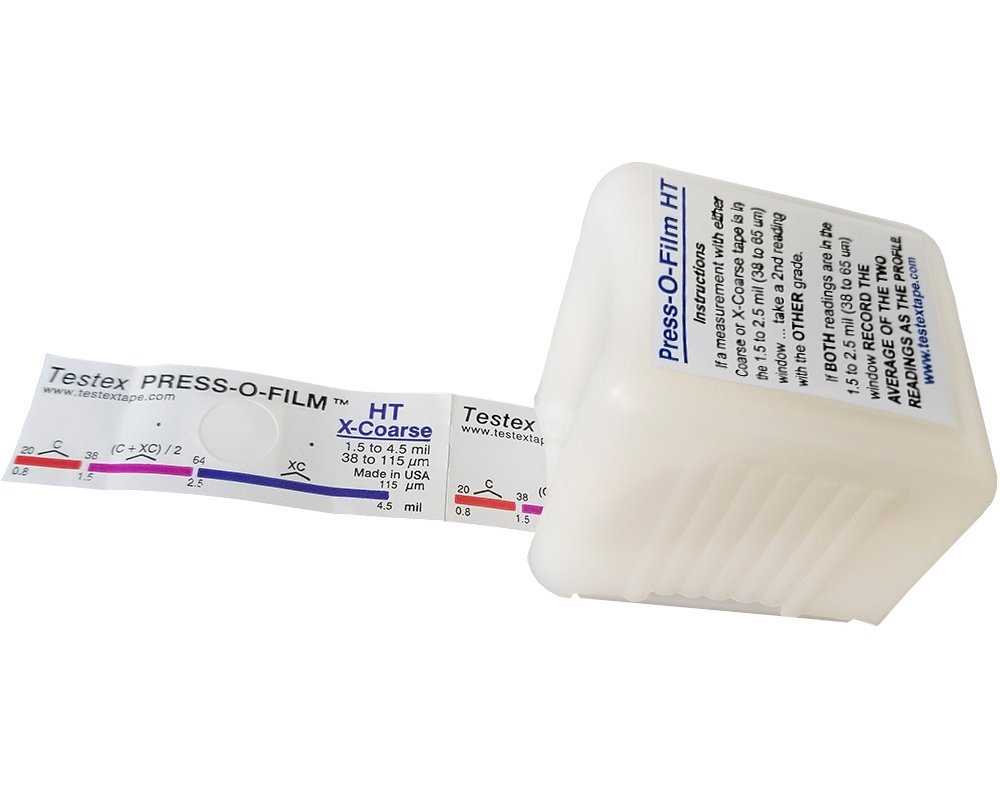

The Testex Tape Standard is available in different grades, each representing a specific range of surface profiles. The grade is indicated by the thickness of the foam layer on the tape. The higher the grade, the rougher the surface profile it can measure. This allows manufacturers to select the appropriate grade of Testex Tape Standard based on the expected surface profile of their substrate.

Key Features of Testex Tape Standard:

- Self-adhesive tape with compressible foam layer

- Leaves an imprint of the surface profile

- Used with a depth micrometer for measurement

- Ensures the surface profile meets a certain standard

- Available in different grades to measure various surface profiles

Importance of Testex Tape Standard

The Testex tape standard is a crucial tool in the field of surface preparation and coating inspection. It provides a reliable and standardized method for measuring surface profile or roughness. This is especially important in industries where proper surface preparation is essential for the successful application of coatings, such as the automotive, aerospace, and marine industries.

Accurate measurement of surface profile: The Testex tape standard allows inspectors to accurately measure the surface profile of a substrate before applying a coating. This is important because the surface profile directly affects the adhesion and performance of the coating. By using the Testex tape standard, inspectors can ensure that the correct surface profile is achieved, leading to better coating adhesion and durability.

Quality control: The Testex tape standard is an invaluable tool for quality control in the coating industry. It allows companies to ensure that the surface profile meets the specified requirements and standards. By measuring the surface profile using the Testex tape, companies can identify any deviations from the desired profile and take corrective action if necessary. This helps to prevent coating failures and ensures that the finished product meets the required quality standards.

Consistency and repeatability: The Testex tape standard provides a consistent and repeatable method for measuring surface profile. This is important for comparing measurements taken at different times or by different inspectors. By using the Testex tape standard, companies can ensure that measurements are consistent and comparable, making it easier to identify any changes in the surface profile over time.

Compliance with industry standards and regulations: Many industries have specific standards and regulations regarding surface preparation and coating application. The use of the Testex tape standard helps companies comply with these standards by providing a recognized and accepted method for measuring surface profile. This is important for ensuring the safety, performance, and longevity of the coated products.

In conclusion, the Testex tape standard plays a crucial role in surface preparation and coating inspection. It allows for accurate measurement of surface profile, ensures quality control, provides consistency and repeatability, and helps companies comply with industry standards and regulations. By using the Testex tape standard, companies can ensure the successful application of coatings and the longevity of their products.

How to Use Testex Tape Standard

Testex Tape Standard is a widely used tool for measuring surface roughness. It provides an accurate and reliable way to assess the profile of a surface, which is important for ensuring proper adhesion of coatings. Here are some steps to follow when using Testex Tape Standard:

1. Prepare the Surface

Before using Testex Tape Standard, the surface should be cleaned and free from any contaminants or loose particles. This can be done by brushing or wiping the surface with a clean cloth. It is important to ensure that the surface is smooth and even before proceeding.

2. Apply Testex Tape

Take a piece of Testex Tape and remove the protective backing. Firmly press the adhesive side of the tape onto the surface, ensuring that it covers the desired area. Make sure the tape is applied evenly and smoothly without any wrinkles or bubbles. Use a roller or a finger to apply pressure and ensure good contact between the tape and the surface.

3. Remove the Testex Tape

After a few seconds, carefully peel off the Testex Tape from the surface. Take care not to stretch or distort the tape while removing it. The adhesive side of the tape should now have a replica of the surface profile.

4. Measure the Replica

Using a Testex Tape reader or a magnifying glass with a calibrated scale, measure the peak-to-valley height of the replica. This measurement will provide an indication of the surface roughness. It is important to follow the manufacturer’s instructions for reading and interpreting the measurements accurately.

By following these steps, you can effectively use Testex Tape Standard to assess surface roughness and ensure the proper adhesion of coatings.

Steps to Apply Testex Tape

The Testex tape is a standard method used to measure the roughness or profile of a surface. This tape is commonly used in industries such as painting, coating, and corrosion prevention. The following steps outline how to apply Testex tape properly:

- Prepare the surface: Before applying the Testex tape, make sure the surface is clean and free from any dirt, debris, or loose paint. Use a suitable cleaning method such as sandblasting or wire brushing to remove any contaminants.

- Peel and press: Peel off the protective backing from the Testex tape to expose the adhesive side. Press the tape firmly onto the surface, ensuring that it adheres evenly and completely.

- Apply pressure: Once the tape is applied, use a Testex press-o-film roller or a similar device to apply even pressure across the tape. This ensures that the tape conforms to the surface and captures an accurate profile.

- Remove the tape: After applying pressure, carefully remove the Testex tape from the surface. Start at one edge and slowly peel it off, making sure not to disturb or damage the profiled impressions left by the tape.

To obtain accurate results, it is important to follow these steps closely when applying Testex tape. By preparing the surface, properly applying the tape, and removing it carefully, you can ensure a precise measurement of the surface roughness or profile.

Tips for Using Testex Tape Standard

When using Testex Tape Standard to measure the surface profile of a substrate, there are several tips and best practices to keep in mind to ensure accurate and reliable results. Here are some key tips to consider:

1. Prepare the Surface

Before applying the Testex tape, it is important to properly prepare the surface being measured. This includes cleaning the surface to remove any dirt, debris, or loose particles that could affect the accuracy of the measurements. Use a suitable cleaning agent and ensure that the surface is completely dry before proceeding.

2. Apply the Tape

When applying the Testex tape, ensure that it is pressed firmly onto the prepared surface to achieve good adhesion. Avoid stretching or distorting the tape, as this can impact the accuracy of the measurements. Make sure that the tape is applied smoothly and without air bubbles or wrinkles.

3. Remove the Tape

After the Testex tape has been applied for the desired amount of time, carefully remove it from the surface. The tape should be pulled off in one smooth motion, at a consistent speed. Avoid jerking or twisting the tape, as this can affect the consistency of the measurements.

4. Measure the Tape

Once the Testex tape has been removed, the surface profile can be measured using a suitable measuring device, such as a precision spring-loaded micrometer. Place the micrometer on the tape and take multiple readings at various points to ensure accuracy. Record the measurements and calculate the average value to determine the surface profile.

5. Consider Calibration

Regular calibration of the measuring device used in conjunction with Testex tape is important to ensure accurate and reliable results. Follow the manufacturer’s instructions for calibration and perform it regularly to maintain the accuracy of the measurements.

By following these tips and best practices, you can effectively use Testex Tape Standard to measure the surface profile of substrates and obtain accurate results for your projects.

Benefits of Testex Tape Standard

The Testex Tape Standard is a widely used and highly effective tool for measuring surface roughness. It offers several benefits that make it an ideal choice for professionals in various industries.

First and foremost, the Testex Tape Standard provides accurate and reliable measurements. Its precision design ensures consistent results, allowing users to confidently assess the roughness of a surface. This accuracy is crucial in many applications, such as determining the quality of a coating or assessing the level of surface preparation before applying a new finish.

- Easy to Use: The Testex Tape Standard is simple to use, making it accessible to professionals of all experience levels. Its intuitive design allows users to quickly and easily obtain surface roughness measurements with minimal training. This saves time and effort, making it an efficient tool for on-site inspections and quality control.

- Portable: The compact and lightweight nature of the Testex Tape Standard makes it highly portable. It can be easily carried to different locations, allowing for measurements to be taken in various environments. This versatility is particularly beneficial for professionals who need to assess surface roughness in different locations or on multiple projects.

- Cost-Effective: The Testex Tape Standard is an affordable option for measuring surface roughness. It offers an excellent cost-to-performance ratio, providing accurate results without breaking the bank. This cost-effectiveness makes it an attractive choice for businesses of all sizes, from small contractors to large industrial operations.

In conclusion, the Testex Tape Standard offers several key benefits for professionals in need of precise surface roughness measurements. Its accuracy, ease of use, portability, and cost-effectiveness make it a valuable tool in industries that rely on quality control and surface preparation. With the Testex Tape Standard, professionals can confidently assess and measure surface roughness with ease and efficiency.

Accurate Coating Thickness Measurement

Accurate coating thickness measurement is essential in various industries such as automotive, aerospace, and manufacturing. It ensures the quality and performance of the finished products, as well as compliance with industry standards and regulations. Testex tape standard is a reliable tool for achieving precise coating thickness measurements.

The Testex tape standard is a widely recognized method for determining the thickness of coatings. It consists of a compressible foam tape with a specified thickness and a non-compressible steel ruler with micrometer graduations. The tape is pressed onto the coated surface, and the depth of the compression is measured using the steel ruler. This measurement provides an accurate indication of the coating thickness.

The Testex tape standard offers several advantages over other coating thickness measurement methods. Firstly, it is non-destructive, allowing for repeated measurements without damaging the coating or the underlying substrate. This is particularly important when evaluating the integrity of coatings on sensitive or expensive materials.

Additionally, the Testex tape standard is easy to use and does not require specialized equipment or training. The procedure can be performed by technicians on the field, providing quick and convenient results. Moreover, the tape standard offers a cost-effective solution for coating thickness measurement, as it eliminates the need for expensive instrumentation.

In conclusion, accurate coating thickness measurement is crucial in various industries, and the Testex tape standard is a reliable and efficient tool for achieving precise results. Its non-destructive nature, ease of use, and cost-effectiveness make it a preferred method for evaluating coating thickness and ensuring the quality and performance of finished products.