For those seeking certification to operate large machinery, proper knowledge and skill assessment are key. Passing the necessary assessments ensures safety and efficiency in the workplace, protecting both operators and others in the environment. Understanding the structure of the evaluation and preparing for it effectively are crucial steps in achieving success.

Understanding the Process

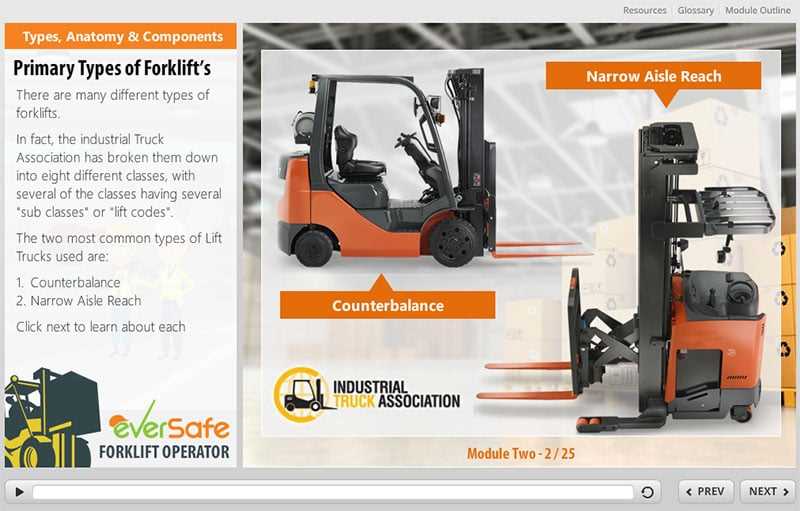

The evaluation consists of both written and practical components. The written portion assesses theoretical knowledge of machine handling, safety protocols, and regulations. The hands-on portion evaluates practical skills, ensuring the individual can operate the machinery effectively in real-world scenarios.

Common Questions Encountered

- What are the key safety procedures when operating large machines?

- How do you handle a situation where the equipment malfunctions?

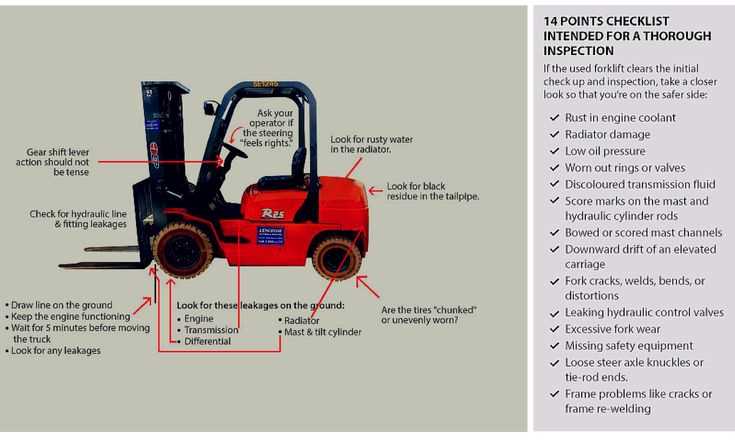

- What are the proper maintenance checks to ensure smooth operation?

Preparation Tips for Success

Focus on understanding the machine’s controls and mechanisms. Study the guidelines set forth by industry standards, as these are commonly reflected in both the written and practical evaluations. Practicing operating the machinery under supervision will provide confidence when facing the hands-on assessment.

Avoiding Common Mistakes

Rushing through the study process is a common mistake. Taking time to thoroughly review all materials and understanding the theory behind machine operation will provide better results than memorizing answers. Additionally, neglecting the practical experience may hinder one’s ability to perform well in the real-world portion of the evaluation.

What to Expect During the Evaluation

During the assessment, both knowledge and physical ability are put to the test. Prepare for unexpected scenarios that may occur during operation. Showing proficiency in handling diverse situations will ensure a successful outcome.

Safety Guidelines for Heavy Equipment Operators

When operating large machinery, following safety protocols is crucial for preventing accidents and ensuring smooth operations. It is essential to have a solid understanding of the rules and techniques that guarantee both personal and team safety. This section will explore the key safety measures, the structure of assessments, common questions, how to prepare, and mistakes to avoid.

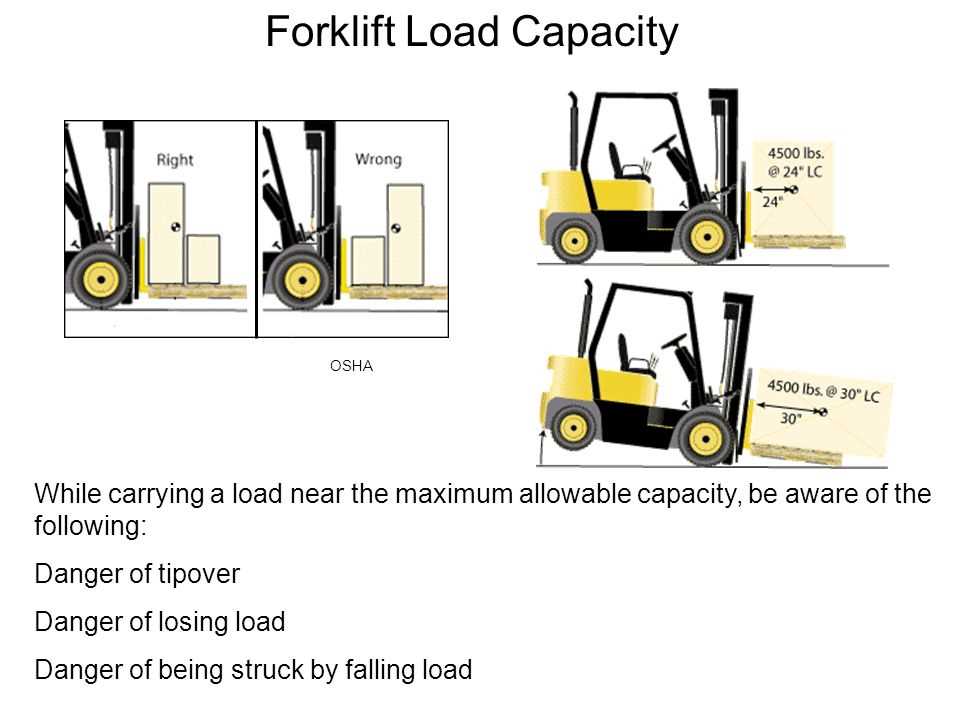

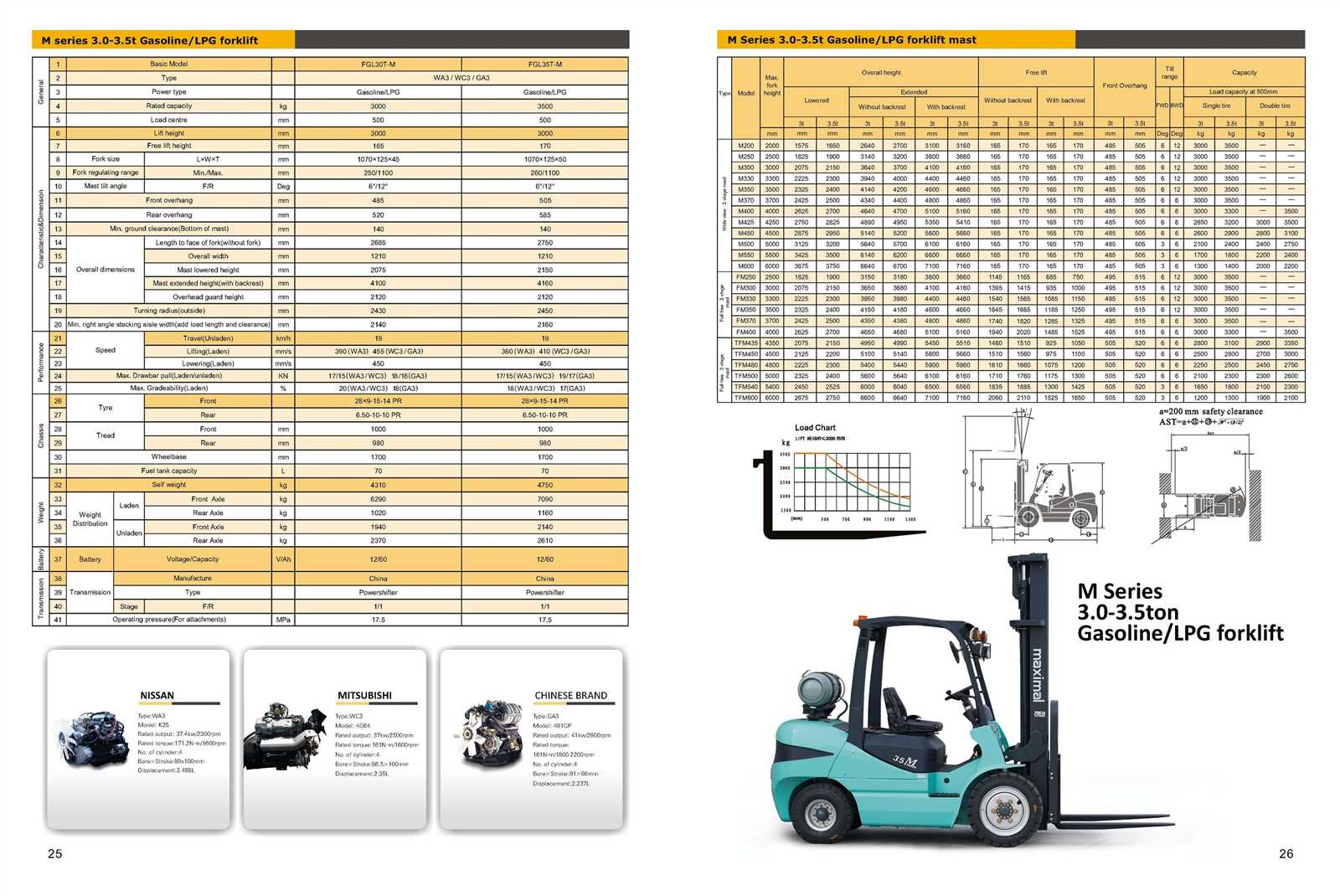

Essential Safety Measures

Before starting, operators should be familiar with machine inspection procedures, secure loading and unloading practices, and proper handling techniques. Ensuring the equipment is in good condition and understanding emergency responses are fundamental for minimizing risks during operation. Always prioritize safety to avoid injuries and equipment damage.

Assessment Structure and Common Queries

The evaluation includes both written assessments and practical exercises to verify theoretical knowledge and operational skills. Expect questions related to safe handling practices, emergency protocols, and equipment maintenance. Familiarizing yourself with the structure of the evaluation will increase your chances of success.

To get ready for the assessment, review key safety guidelines, operational procedures, and past questions. It is also important to practice under supervision to build confidence in real-life scenarios.

Avoid common mistakes like rushing through preparation or neglecting hands-on practice. Understanding the theory behind machine operation is just as important as knowing how to control it practically.

During the practical portion, demonstrate your ability to handle the machinery safely and efficiently in various situations. Expect the examiner to assess your competency in executing safety checks, proper movement, and adherence to operational procedures.