For those looking to operate heavy machinery, passing the required assessments is a crucial step. Mastering the necessary knowledge and skills not only ensures safety but also boosts confidence in the workplace. Preparation is key to achieving success in these evaluations, whether for beginners or those aiming for a refresher.

Understanding safety regulations and operational procedures is a significant part of the preparation process. Clear guidelines help operators handle equipment efficiently and prevent accidents. A strong foundation in these areas ensures that individuals can perform their duties safely and in compliance with industry standards.

Forklift Certification Exam Insights

Successfully completing an evaluation for operating heavy equipment requires a comprehensive understanding of both theoretical knowledge and practical skills. Operators must be familiar with key safety protocols, equipment functionality, and efficient handling techniques. By mastering these core elements, individuals can ensure they meet industry standards and contribute to a safer work environment.

Each evaluation consists of multiple components designed to test the candidate’s ability to safely and effectively manage machinery. These assessments are structured to cover various areas, from basic operational understanding to advanced safety measures. Preparing thoroughly for these assessments is essential for both first-time candidates and those looking to renew their qualifications.

Understanding the Exam Requirements

To successfully pass an assessment for operating heavy machinery, it’s crucial to comprehend the key criteria and expectations. These evaluations are designed to ensure that candidates are equipped with the necessary knowledge and skills to operate equipment safely and effectively. Understanding the structure and focus areas of the exam helps prepare individuals for the challenges they may face during the process.

Key areas of the evaluation typically include knowledge of safety protocols, equipment functionality, and best practices for handling different types of machinery. Operational skills are also tested to ensure that candidates can operate equipment competently in real-world scenarios. Preparing for each component of the evaluation is essential to achieving certification and excelling in the field.

Common Questions on Forklift Safety

Ensuring safety when operating lifting equipment is paramount in any work environment. Operators must be well-versed in proper handling techniques, hazard prevention, and emergency response protocols. By addressing common questions related to safety, individuals can gain a deeper understanding of how to minimize risks and protect themselves and others on the job.

What Are the Key Safety Precautions?

Proper training and regular maintenance of the equipment are vital for safe operation. Operators should always conduct pre-operation checks, wear the necessary protective gear, and be aware of their surroundings. Understanding load limits, proper stacking techniques, and safe maneuvering practices helps reduce the risk of accidents and ensures smooth daily operations.

How Should Operators React in Emergencies?

In the event of an emergency, operators must remain calm and act quickly. This includes knowing how to stop the equipment safely, alert others to potential hazards, and follow the established emergency procedures. Being prepared for various situations is essential to ensure quick and effective responses in any unforeseen circumstances.

Key Skills for Passing the Exam

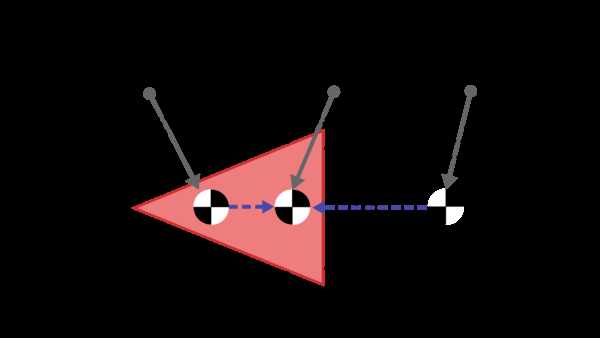

Successfully completing an evaluation for operating lifting equipment requires a combination of knowledge, practical skills, and safety awareness. It is essential to develop a well-rounded understanding of both the theoretical aspects and hands-on handling techniques to perform effectively. Candidates must demonstrate proficiency in various areas to ensure they meet the required standards for certification.

Safety awareness is one of the most important skills to master. Being able to recognize potential hazards and take proactive measures to avoid accidents is vital. Additionally, operators must have a solid understanding of equipment features, handling procedures, and the best practices for operating machinery in diverse environments.

Equally important are the practical abilities to maneuver the equipment safely, including accurate steering, lifting, and positioning of loads. Candidates should also be prepared to demonstrate their ability to assess and adjust to different working conditions, ensuring smooth operations at all times.

How to Prepare for the Exam

Preparing for an evaluation of lifting equipment operation requires focus and dedication. Successful candidates often combine theoretical study with hands-on practice to ensure they are ready for the various components of the assessment. A solid understanding of safety protocols, equipment handling, and operational procedures is essential for passing with confidence.

Study the Fundamentals

Reviewing key topics such as safety regulations, equipment features, and load handling is a critical first step. Focusing on the core principles of operation will help candidates understand the expectations of the evaluation. In addition, it is essential to familiarize oneself with any rules specific to the type of equipment being assessed.

Practice Handling the Equipment

Alongside theoretical preparation, practical experience is vital. Spend time operating the machinery in controlled settings to become familiar with its functions. This hands-on experience will build confidence and ensure smoother performance during the evaluation.

| Preparation Focus | Recommended Action |

|---|---|

| Safety Protocols | Study safety rules and emergency procedures |

| Equipment Knowledge | Learn the key functions and maintenance procedures |

| Practical Skills | Practice maneuvering equipment in various conditions |

| Regulatory Compliance | Understand and follow local safety regulations |

Tips for Success in Equipment Operation Evaluations

Achieving success in evaluations for lifting machinery operation requires a combination of preparation, focus, and practical experience. Operators who consistently perform well in these assessments understand the importance of being both knowledgeable and skilled. By following specific tips and strategies, candidates can significantly improve their chances of passing with ease.

- Know the Basics: Familiarize yourself with the fundamental safety protocols, equipment functionality, and handling techniques.

- Prioritize Safety: Always follow safety guidelines and practice emergency procedures to minimize risks during operation.

- Stay Calm and Focused: Keep a calm mindset during the evaluation to ensure smooth operation and clear decision-making.

- Practice Regularly: Spend time operating the equipment in varied environments to build confidence and proficiency.

- Review Regulations: Ensure you understand all local safety regulations and operational standards relevant to the machinery.

By preparing thoroughly, following the right steps, and maintaining a safety-first attitude, candidates can confidently navigate the evaluation process and succeed with minimal stress.

Post-Assessment Actions and Certification

After completing the evaluation for operating lifting equipment, it is essential to understand the next steps in the process. Successfully passing the evaluation opens the door to certification, which is necessary for legally operating the machinery in professional settings. The actions taken after the assessment play a crucial role in confirming competency and ensuring compliance with safety standards.

Once the evaluation is complete, candidates will receive feedback on their performance. This feedback often includes areas for improvement, as well as a summary of strengths. If successful, operators can proceed to obtain their official certification, which serves as proof of their qualifications. It is important to maintain this certification through ongoing training and adherence to industry best practices.

Additionally, individuals should be aware of the validity period of their certification and stay updated on any changes in safety regulations or operational procedures to ensure continuous compliance with industry standards.