Respiratory protection is an essential part of occupational safety and health, especially in industries where workers are exposed to hazardous airborne contaminants. The proper use and maintenance of respiratory protection equipment is crucial to ensure workers are adequately protected. Taking a respiratory protection quiz can help assess your knowledge and understanding of respiratory protection principles and practices.

By testing your knowledge through a quiz, you can identify any areas of weakness and take steps to address them. The respiratory protection quiz covers various topics, including the types of respiratory protection equipment available, the correct use of such equipment, and the importance of fit testing and training. It also covers the hazards that can be present in different work environments and how respiratory protection can mitigate those hazards. Answering these quiz questions can help reinforce your understanding of respiratory protection and improve your ability to protect yourself and others.

So, without further ado, let’s delve into the answers to some common respiratory protection quiz questions. These answers will provide you with a better understanding of respiratory protection principles and help you enhance your respiratory protection practices in the workplace. Remember, it’s essential to consult your employer’s respiratory protection program and follow their guidelines to ensure the highest level of protection for yourself and your colleagues.

Respiratory Protection Quiz Answers

Respiratory protection is a crucial aspect of workplace safety, especially in environments that expose workers to harmful substances or airborne contaminants. To ensure that workers are adequately protected, it is important to train them on the proper usage and maintenance of respiratory protective equipment (RPE). This quiz aims to test your knowledge of respiratory protection and provide answers to common questions.

1. What is the purpose of respiratory protective equipment (RPE)?

- Answer: The purpose of RPE is to protect the wearer’s respiratory system from inhaling hazardous substances, such as dust, fumes, gases, or vapors, that may be present in the workplace environment.

2. When should respiratory protective equipment be used?

- Answer: RPE should be used when there is a risk of inhaling harmful substances that cannot be controlled through other measures, such as engineering controls (e.g., ventilation) or administrative controls (e.g., reducing exposure time).

3. How should you select the appropriate RPE?

- Answer: The selection of RPE should be based on the type and concentration of contaminants present in the workplace, as well as the duration and frequency of exposure. It is important to consider factors such as the respiratory protection factor (RPF), fit testing requirements, and comfort of the equipment.

4. What are the key steps for properly using RPE?

- Answer: The key steps for using RPE include inspecting the equipment before use, ensuring a proper fit, conducting seal checks, donning and adjusting the equipment correctly, and performing regular maintenance and cleaning.

5. What are the common types of RPE?

- Answer: Common types of RPE include disposable masks, half-face respirators, full-face respirators, powered air purifying respirators (PAPRs), and self-contained breathing apparatus (SCBA). The choice of RPE depends on the level of protection required and the specific hazards present.

By understanding the importance of respiratory protection and knowing how to properly use and maintain RPE, workers can effectively safeguard their health and well-being in hazardous work environments.

Understanding Respiratory Hazards

Respiratory hazards refer to substances that can potentially harm the respiratory system. These hazards can be present in various environments, such as workplaces, homes, and outdoor settings. It is crucial to have a good understanding of these hazards and their potential effects in order to take appropriate measures for protection.

Common Respiratory Hazards:

- Dust: Dust particles can be found in many industries, such as construction, mining, and agriculture. Inhaling dust can lead to respiratory irritation, allergies, and even long-term lung diseases.

- Chemicals: Many chemicals, such as solvents, gases, and fumes, can have harmful effects on the respiratory system. They can cause irritation, inflammation, or damage to the lungs.

- Smoke: Smoke from fires or tobacco contains various toxic substances, including carbon monoxide and fine particles. Breathing in smoke can lead to respiratory distress and increase the risk of lung diseases.

- Biological Agents: Biological agents, such as bacteria, viruses, and fungi, can also pose respiratory hazards. They can cause infections and respiratory diseases, especially in healthcare settings.

Protection Measures:

- Proper Ventilation: Ensuring adequate ventilation in workplaces and other indoor environments can help reduce the concentration of respiratory hazards.

- Personal Protective Equipment (PPE): Wearing appropriate respiratory protection, such as masks or respirators, can help filter out harmful particles or gases.

- Safe Practices: Following safe work practices, such as proper handling and storage of hazardous substances, can minimize exposure to respiratory hazards.

- Regular Monitoring: Regular monitoring of air quality and respiratory health can help identify potential hazards and take necessary actions to prevent respiratory problems.

- Education and Training: Providing education and training on respiratory hazards and their prevention is essential to ensure that individuals are aware of the risks and know how to protect themselves.

By understanding respiratory hazards and implementing appropriate measures, individuals can reduce the risk of respiratory problems and maintain a healthy respiratory system. It is important to stay informed and take proactive steps to protect respiratory health in various environments.

Types of Respiratory Protection

The use of respiratory protection is crucial in certain work environments where employees may be exposed to harmful airborne contaminants. There are several types of respiratory protection devices available, each designed to provide a specific level of protection. Here are some common types:

- N95 Respirators: N95 respirators are designed to filter out at least 95% of airborne particles, including small droplets and aerosols. They are commonly used in healthcare settings and construction sites where workers may be exposed to infectious diseases or hazardous materials.

- Half-face Respirators: Half-face respirators cover the nose, mouth, and chin of the wearer. They use replaceable filters to remove particulates from the air. This type of respiratory protection is often used in industries such as painting, construction, and mining.

- Full-face Respirators: Full-face respirators cover the entire face, providing both respiratory protection and eye protection. They use the same filter cartridges as half-face respirators and are used in environments with higher levels of airborne contaminants or gases.

- Air-purifying Respirators: Air-purifying respirators use filters or cartridges to remove contaminants from the air. They are often used in environments with known airborne hazards, such as chemicals, gases, or particulate matter.

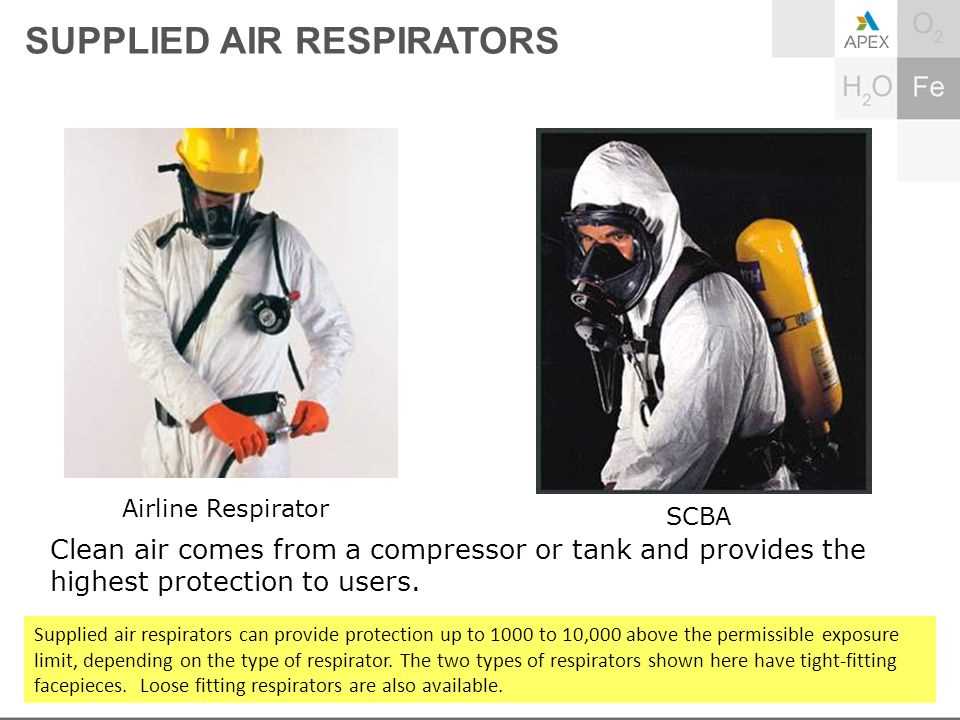

- Supplied-air Respirators: Supplied-air respirators provide clean, breathable air from a remote source, such as an air tank or an air compressor. They are used in environments where the air quality is compromised or where workers need to be protected from oxygen-deficient atmospheres.

It is important to select the appropriate type of respiratory protection based on the specific hazards present in the work environment. Regular training and fit testing should also be conducted to ensure that the respirators fit properly and provide effective protection for the wearer.

Respirator Fit Testing

Respirator fit testing is a critical part of ensuring the proper fit and effectiveness of respiratory protection equipment. It is important for individuals who are required to wear respirators in the workplace to undergo fit testing to ensure that the respirator forms a tight seal on their face, minimizing the risk of exposure to harmful airborne contaminants.

There are two main types of fit testing: qualitative fit testing and quantitative fit testing. Qualitative fit testing involves the use of specific test agents, such as irritant smoke or saccharin solution, to determine if the respirator wearer can detect the agent’s taste or smell. This method relies on the wearer’s subjective response and is used for non-quantitative respirators. Quantitative fit testing, on the other hand, uses instruments to measure the concentration of particles inside and outside the respirator to determine the fit factor, which is a quantitative measure of the respirator’s fit.

Fit testing should be conducted:

- Before an individual starts wearing a respirator for the first time

- Annually or when there are changes to the individual’s facial characteristics that may affect the respirator fit

- If a different model or size of respirator is used

- If there are changes to the respirator’s design, such as the addition of a new seal or valve

It is important for employers to provide employees with proper training on how to wear and fit test respirators correctly. In addition, employees should be knowledgeable about the importance of fit testing and the potential consequences of wearing a poorly fitting respirator. By conducting regular fit testing and ensuring the proper fit of respirators, employers can help protect their employees from hazardous airborne contaminants and maintain a safe working environment.

Maintenance and Care of Respiratory Equipment

Ensuring the proper maintenance and care of respiratory equipment is crucial for its effectiveness in protecting the user from harmful airborne contaminants. Regular cleaning and inspection help to identify any damage or wear that may compromise the equipment’s ability to provide adequate respiratory protection.

1. Cleaning: Cleaning respiratory equipment should be done regularly to remove any dirt, dust, or debris that may accumulate on the surfaces. Use mild detergent or soap and warm water to gently clean the equipment. Avoid using harsh chemicals or abrasive materials that could damage the equipment. Rinse thoroughly and allow the equipment to air dry before storing or using it again.

2. Inspection: Conducting regular inspections of respiratory equipment is essential to identify any signs of damage or wear. Inspect the straps, seals, valves, and filters for any cracks, tears, or deterioration. Check that the equipment is properly assembled and functioning correctly. Any damaged or worn parts should be replaced immediately to ensure the proper functioning of the respiratory equipment.

3. Storage: Proper storage of respiratory equipment is crucial to maintain its effectiveness and prolong its lifespan. Store the equipment in a clean, dry, and well-ventilated area away from direct sunlight, extreme temperatures, and chemicals. Use a storage bag or case to protect the equipment from dust, dirt, and damage. Ensure that the equipment is stored in a way that prevents distortion or deformation of any parts.

4. Training and Education: Users of respiratory equipment should receive proper training and education on its use, maintenance, and care. They should be aware of the manufacturer’s instructions and guidelines for cleaning, inspection, and storage. Regular training sessions can help reinforce proper maintenance practices and ensure that users understand the importance of taking care of their respiratory equipment.

By following these guidelines for maintenance and care, users can ensure that their respiratory equipment remains in good working condition and provides the necessary protection when needed. Proper care and maintenance not only extend the lifespan of the equipment but also contribute to the overall safety and well-being of the user.

Common Mistakes in Respiratory Protection

Proper respiratory protection is essential in protecting workers from harmful airborne contaminants. However, there are several common mistakes that can compromise the effectiveness of respiratory protection equipment. It is important for employers and employees to be aware of these mistakes and take steps to avoid them.

1. Incorrect Fit

One of the most common mistakes in respiratory protection is wearing a mask or respirator that does not fit properly. An ill-fitting mask can create gaps between the mask and the face, allowing contaminants to enter. Workers should be trained on how to properly fit and adjust their masks for a secure and comfortable fit.

2. Failure to Perform Seal Check

Another mistake is failing to perform a seal check before entering a contaminated area. A seal check involves covering the filtering facepiece with your hands and exhaling to check for any air leakage. If air escapes from the sides of the mask, it indicates a poor seal and the mask should be adjusted or replaced.

3. Improper Storage and Maintenance

Respiratory protection equipment should be stored in a clean and dry area to prevent damage and contamination. Additionally, regular maintenance and inspection should be performed to ensure that the equipment is in good working condition. Failure to properly store and maintain respiratory protection equipment can compromise its effectiveness.

4. Incorrect Selection of Respirator

Selecting the wrong type of respirator for the specific hazard is another common mistake. Different types of respirators are designed to protect against specific hazards, such as particulates, gases, or chemicals. It is important to correctly identify the hazard and select the appropriate respirator for maximum protection.

By avoiding these common mistakes, employers and employees can ensure that respiratory protection is properly implemented and effectively protects workers from harmful airborne contaminants.

Important Considerations for Respiratory Protection

When it comes to respiratory protection, there are several important factors to consider to ensure the safety and well-being of individuals. These considerations include:

- Fitting: It is crucial to select respirators that fit properly and provide a secure seal to the face. The use of fit testing techniques can help determine the appropriate size and fit for individuals.

- Filtering Efficiency: Respirators should have appropriate filtering efficiencies to ensure the protection against airborne contaminants. The effectiveness of the filters should be evaluated based on the specific hazards present.

- Comfort: Comfort is an essential aspect of respiratory protection. Uncomfortable respirators may discourage individuals from wearing them consistently, which can compromise their safety. It is important to choose respirators that are comfortable and do not cause excessive breathing resistance.

- Training and Education: Proper training and education are vital to ensure the correct use of respiratory protection. Individuals should be educated on the proper donning and doffing procedures, maintenance, and storage of the respirators.

- Regulatory Compliance: Compliance with applicable regulations and standards is imperative. Employers should ensure that the selected respiratory protection meets the regulatory requirements set by local authorities.

In conclusion, respiratory protection is a critical aspect of ensuring the safety and health of individuals exposed to respiratory hazards. By considering factors such as fitting, filtering efficiency, comfort, training, and regulatory compliance, individuals can select and use the appropriate respiratory protection to minimize the risk of respiratory illnesses and injuries.