Valve body tester is a crucial tool used in various industries to evaluate the performance, efficiency, and reliability of valves. Whether it’s for oil and gas, chemical, or manufacturing sectors, having a well-functioning valve system is vital for smooth operations and safety. A valve body tester allows for comprehensive testing of valves under different conditions, ensuring that they meet industry standards and requirements.

One of the main advantages of using a valve body tester is the ability to simulate real-world operating conditions. By subjecting valves to varying pressure levels, temperatures, and flow rates, the tester provides a realistic assessment of their performance. This helps identify any potential issues or weaknesses in the valve, allowing for timely repairs or replacements, and preventing costly damages or accidents.

Another key feature of valve body testers is their ability to measure and analyze key parameters such as leakage rate, pressure drop, and flow characteristics. These tests provide valuable data for engineers and technicians to optimize valve design, identify any defects or abnormalities, and ensure that valves operate within desired parameters. This helps improve the overall efficiency and reliability of the valve system, leading to enhanced productivity and reduced downtime.

In addition to testing individual valves, valve body testers can also evaluate the performance of valve assemblies. This is particularly important in complex systems where multiple valves work together to control and regulate fluid flow. By testing the entire assembly, engineers can ensure that all valves interact correctly and operate as desired. This comprehensive testing approach minimizes the chances of system failure, improves system performance, and enhances overall operational safety.

In conclusion, valve body testers play a crucial role in maintaining the efficiency and reliability of valve systems in industrial settings. By simulating real-world conditions and providing comprehensive testing capabilities, these tools help identify potential issues, optimize valve design, and ensure that valves meet industry standards. Investing in a valve body tester is a wise decision for industries looking to enhance operational safety, productivity, and cost-effectiveness.

Valve Body Tester: Improve your Equipment Efficiency

In the automotive industry, the efficiency of valve bodies is crucial for the overall performance of a vehicle. A valve body tester is an essential tool for evaluating the functionality and efficiency of valve bodies. By simulating real-world operating conditions, this tester allows technicians to diagnose and troubleshoot any issues in the valve body, ensuring optimal performance.

Key Features:

- Realistic simulation: The valve body tester replicates actual operating conditions, providing accurate and reliable results. This realistic simulation allows technicians to identify any potential problems and make necessary adjustments.

- Detailed analysis: The tester provides detailed analysis of the valve body’s performance, including flow rates, pressure levels, and shift timing. This information helps technicians understand the overall efficiency of the valve body and make data-driven decisions.

- Fault detection: The valve body tester can detect and diagnose faults in the valve body, such as sticking valves or worn out components. By identifying these issues early on, technicians can prevent further damage and improve the longevity of the valve body.

- Time-saving: Using a valve body tester significantly reduces the time required to diagnose and troubleshoot valve body problems. This allows technicians to efficiently address any issues and minimize downtime.

Overall, a valve body tester is a valuable tool for automotive technicians looking to improve the efficiency of their equipment. By accurately diagnosing and troubleshooting valve body problems, technicians can optimize the performance of vehicles and ensure customer satisfaction.

Overview

The Valve Body Tester is a specialized testing device used in the automotive industry to assess the functionality and performance of valve bodies in automatic transmissions. The valve body is a crucial component responsible for controlling the flow of transmission fluid, directing it to various clutches and gears to enable smooth gear shifting. It is essential to ensure that the valve body is functioning correctly to maintain the overall performance and efficiency of the transmission system.

The Valve Body Tester is designed to simulate the real-world conditions that the valve body will encounter during operation. It allows technicians and engineers to evaluate the valve body’s response to different pressures, fluid temperatures, and shifting patterns. By subjecting the valve body to controlled testing scenarios, potential issues and malfunctions can be identified and addressed before they cause major problems or failures in the transmission.

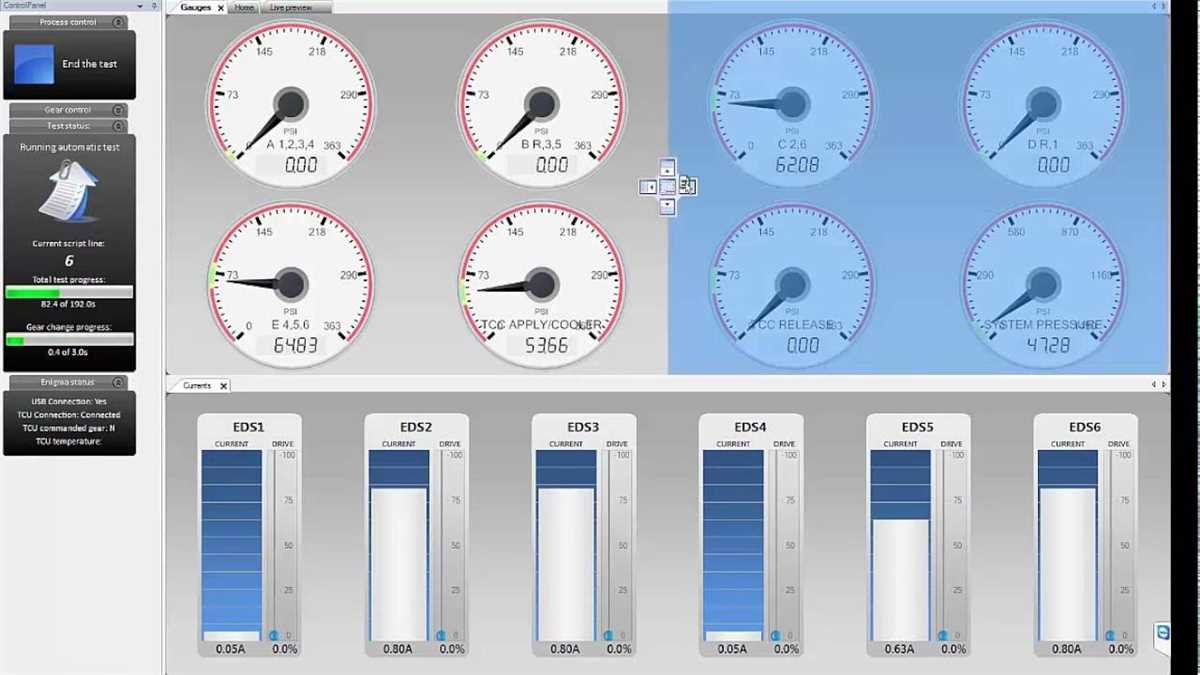

One of the key features of the Valve Body Tester is its ability to measure and analyze the hydraulic pressures generated by the valve body. It provides detailed pressure readings for each control channel, allowing technicians to identify any inconsistencies or abnormalities that may affect the performance of the valve body. The tester also enables the visualization of fluid flow patterns, which can help detect any blockages or restrictions in the valve body passages.

The Valve Body Tester offers a user-friendly interface that allows technicians to input and adjust the testing parameters easily. It provides real-time data and graphical representations of the valve body’s performance, making it easier to interpret and analyze the results. Additionally, the tester can store and retrieve testing profiles, allowing for efficient testing procedures and comparisons between different valve bodies.

In summary, the Valve Body Tester is an essential tool for automotive professionals involved in transmission maintenance and repair. It enables accurate and comprehensive testing of valve bodies, ensuring their optimal performance and preventing potential transmission failures. By using the Valve Body Tester, technicians can diagnose and address issues early on, leading to safer and more efficient vehicles.

Benefits of Using a Valve Body Tester

Valve body testers are essential tools in the automotive industry for testing and diagnosing issues with the valve bodies of automatic transmission systems. These testers offer numerous benefits for both mechanics and customers, ensuring the efficient functioning of vehicles and reducing repair costs.

1. Accurate and reliable diagnosis: A valve body tester allows mechanics to accurately diagnose issues with the valve body and pinpoint the exact problem areas. It provides real-time data and feedback, ensuring precise analysis and reducing the risk of misdiagnosis. This leads to more efficient repairs and saves both time and money for both the mechanic and the customer.

2. Cost-effective repairs: By using a valve body tester, mechanics are able to identify the specific issues within the valve body, allowing them to perform targeted repairs rather than replacing the entire valve body assembly. This significantly reduces the cost of repairs, as only the faulty components need to be repaired or replaced. Additionally, it helps avoid unnecessary replacement of parts, minimizing overall repair expenses.

3. Improved vehicle performance: A valve body tester enables mechanics to optimize the hydraulic pressure in the valve body, ensuring proper shifting and smooth transmission operation. By accurately adjusting the pressure, mechanics can improve the vehicle’s overall performance, including acceleration, shifting, and fuel efficiency. This enhances the driving experience for customers and prolongs the lifespan of the transmission system.

4. Increased customer satisfaction: By utilizing a valve body tester, mechanics are able to provide accurate diagnoses and efficient repairs, resulting in improved customer satisfaction. Customers benefit from reduced downtime, lower repair costs, and improved vehicle performance. They can rely on the expertise of the mechanic and have confidence in the repairs performed, leading to enhanced trust and loyalty.

In conclusion, the use of a valve body tester offers numerous benefits in the automotive industry. It ensures accurate diagnosis, cost-effective repairs, improved vehicle performance, and increased customer satisfaction. Mechanics can rely on these tools to deliver precise results and provide efficient services, resulting in a win-win situation for both mechanics and customers.

Main Features of Valve Body Tester

The Valve Body Tester is a specialized device designed to test and diagnose the functionality of valve bodies in automatic transmissions. It is an essential tool for automotive technicians and professionals in the transmission repair industry. The tester is equipped with various features that allow for accurate and efficient testing of valve bodies.

One of the main features of the Valve Body Tester is its ability to simulate different operating conditions and pressures that a valve body would experience in a real transmission. This allows technicians to verify the performance and responsiveness of the valves and solenoids within the valve body. The tester can replicate the various positions and movements of the valves, providing a comprehensive evaluation of their functionality.

- Simulates real-life operating conditions

- Verifies performance and responsiveness of valves and solenoids

- Replicates positions and movements of valves

Another key feature of the Valve Body Tester is its ability to measure and display the hydraulic pressure generated by the valves. By accurately measuring the pressure, technicians can detect any irregularities or blockages in the valve body, which may indicate potential issues in the transmission. The tester provides real-time pressure readings, allowing for immediate diagnosis and troubleshooting.

The Valve Body Tester also comes equipped with a user-friendly interface and intuitive controls, making it easy to operate and navigate through the various testing procedures. It provides detailed test reports, which can be used for documentation and analysis. Additionally, the tester is compatible with a wide range of valve body models, making it a versatile tool for transmission repair shops.

- Measures and displays hydraulic pressure

- Detects irregularities or blockages in the valve body

- User-friendly interface and intuitive controls

- Generates detailed test reports

- Compatible with a wide range of valve body models

In conclusion, the Valve Body Tester offers a comprehensive and reliable solution for testing valve bodies in automatic transmissions. Its ability to simulate operating conditions, measure hydraulic pressure, and provide detailed test reports makes it an indispensable tool for efficient and accurate diagnosis of valve body issues.

Choosing the Right Valve Body Tester for your Needs

When it comes to testing valve bodies, having the right equipment is crucial. A valve body tester is an essential tool for accurately evaluating the performance and functionality of valve bodies. With so many options available in the market, it can be overwhelming to choose the right one for your needs.

1. Compatibility: The first and foremost factor to consider is the compatibility of the valve body tester with the valve bodies you will be working with. Different testers may be designed for different types of valve bodies, so it is important to ensure that the tester you choose is compatible with the specific valve bodies you will be testing. This will ensure accurate and reliable results.

2. Pressure Range: Another important aspect to consider is the pressure range of the valve body tester. It is crucial to choose a tester that can provide the required pressure levels for testing the valve bodies you work with. Ensure that the tester can generate the necessary pressure range to accurately simulate real-world conditions.

3. Features: Assess the features offered by different valve body testers and determine which ones are essential for your testing needs. Some important features to consider include the ability to simulate different driving conditions, customizable testing parameters, data logging capabilities, and user-friendly interface. Make a list of features that are crucial for your specific testing requirements and select a tester that offers them.

4. Reliability and Durability: A valve body tester is a significant investment, so it is important to choose one that is reliable and durable. Look for a tester that is built with high-quality materials and has a solid construction. Read reviews and seek recommendations from industry professionals to gauge the reliability and durability of different valve body testers.

5. After-sales Support: Lastly, consider the after-sales support provided by the manufacturer. A reliable manufacturer should offer technical support, training, and maintenance services for their valve body testers. Look for manufacturers who provide comprehensive support and have a good reputation in the industry.

By considering these factors, you can select the right valve body tester that meets your needs and ensures accurate and reliable testing of valve bodies.

How to Use a Valve Body Tester

A valve body tester is an essential tool for testing and diagnosing various valve bodies used in automatic transmissions. It is designed to simulate the conditions and pressures that the valve body will experience during normal operation. Here are the steps on how to use a valve body tester effectively:

Step 1: Preparation

- Ensure that the valve body tester is connected to the appropriate power source and turned on.

- Inspect the valve body for any signs of damage or wear. Replace any faulty components before testing.

- Connect the valve body to the tester using the appropriate adapters and fittings.

Step 2: Set up the Test Parameters

- Refer to the manufacturer’s instructions or specifications to determine the correct test parameters for the valve body being tested.

- Adjust the pressure settings on the tester to match the recommended values for the specific valve body.

- Set the test duration and any other relevant parameters as specified.

Step 3: Conduct the Test

- Activate the valve body tester to apply the desired pressure and simulate normal transmission conditions.

- Observe the valve body’s response to the applied pressure, noting any irregularities or malfunctions.

- If necessary, adjust the test parameters to replicate different operating conditions and assess the valve body’s performance under varying circumstances.

Step 4: Interpret the Results

- Evaluate the valve body’s performance based on the observed response and compare it to the expected behavior.

- Identify any issues or abnormalities, such as excessive pressure drops, inconsistent shifting, or improper valve operation.

- Based on the test results, determine the appropriate course of action, such as repairing or replacing the valve body components.

By following these steps, you can effectively use a valve body tester to diagnose and troubleshoot issues with automatic transmission valve bodies, helping to ensure optimal performance and reliability.

Maintenance and Care Tips for Valve Body Tester

Proper maintenance and care of your valve body tester is essential for ensuring its longevity and optimal performance. By following these tips, you can significantly extend the lifespan of your equipment and minimize the risk of malfunctions or damage.

Maintenance Tips:

- Regular Cleaning: Clean the valve body tester regularly to remove any dirt, debris, or residue that may accumulate. Use a soft cloth or brush to gently wipe the exterior surfaces and ensure that the internal components are free from any contaminants.

- Lubrication: Apply lubrication to the moving parts of the valve body tester as recommended by the manufacturer. This will help reduce friction and ensure smooth operation.

- Inspect and Replace Parts: Regularly inspect the valve body tester for any signs of wear or damage. Replace any worn-out or damaged parts promptly to prevent further issues.

- Keep it Dry: Avoid exposing the valve body tester to excessive moisture or humidity. Moisture can cause corrosion and damage to the internal components. Store the equipment in a dry and controlled environment when not in use.

Care Tips:

- Handle with Care: Handle the valve body tester with care and avoid dropping or mishandling it. Rough handling can lead to damage to the equipment and affect its accuracy and performance.

- Follow Operating Instructions: Always follow the manufacturer’s instructions when using the valve body tester. Improper operation can lead to damage or inaccurate results.

- Store Properly: Store the valve body tester in a safe and secure location when not in use. Protect it from dust, extreme temperatures, and other potentially damaging elements.

- Regular Calibration: Schedule regular calibrations for your valve body tester to ensure accurate readings. This will help maintain the reliability and precision of the equipment.

By following these maintenance and care tips, you can ensure the longevity and optimal performance of your valve body tester. Regular cleaning, lubrication, inspection, and proper handling will help minimize the risk of malfunctions and extend the lifespan of your equipment. Remember to always refer to the manufacturer’s instructions and schedule regular calibrations to maintain accuracy and reliability.